Bimetal composite pipe end sealing weld technology based on R-shaped groove

A bimetallic composite pipe and groove technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of poor welding seam quality and easy quality defects of bimetallic composite pipes, so as to facilitate construction and labor production. The effect of improving efficiency and reducing the difficulty of sealing and welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

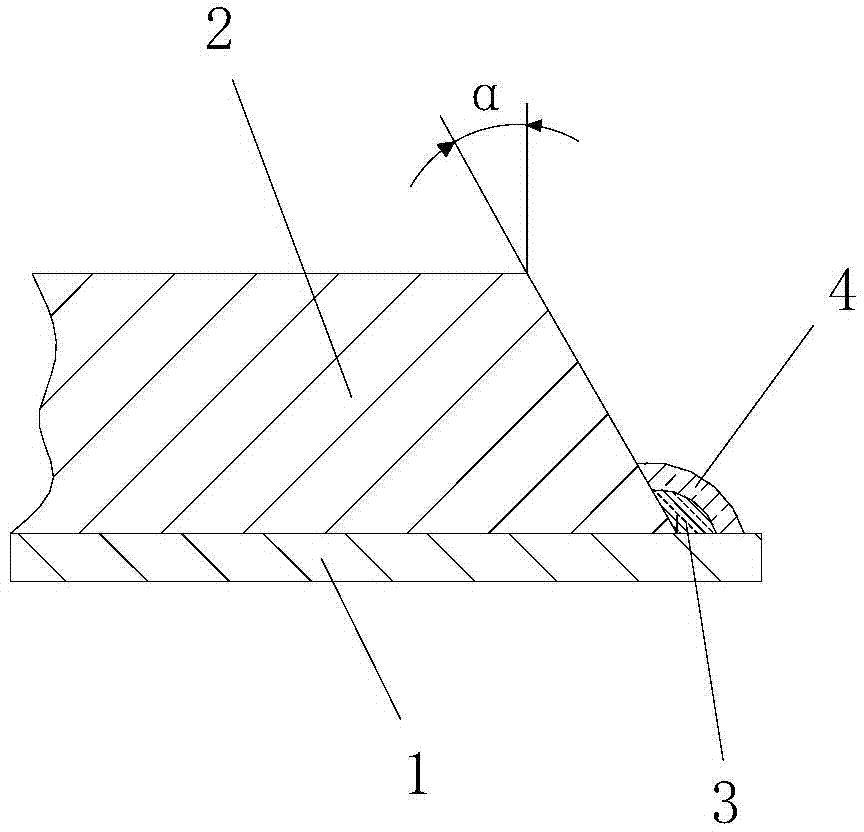

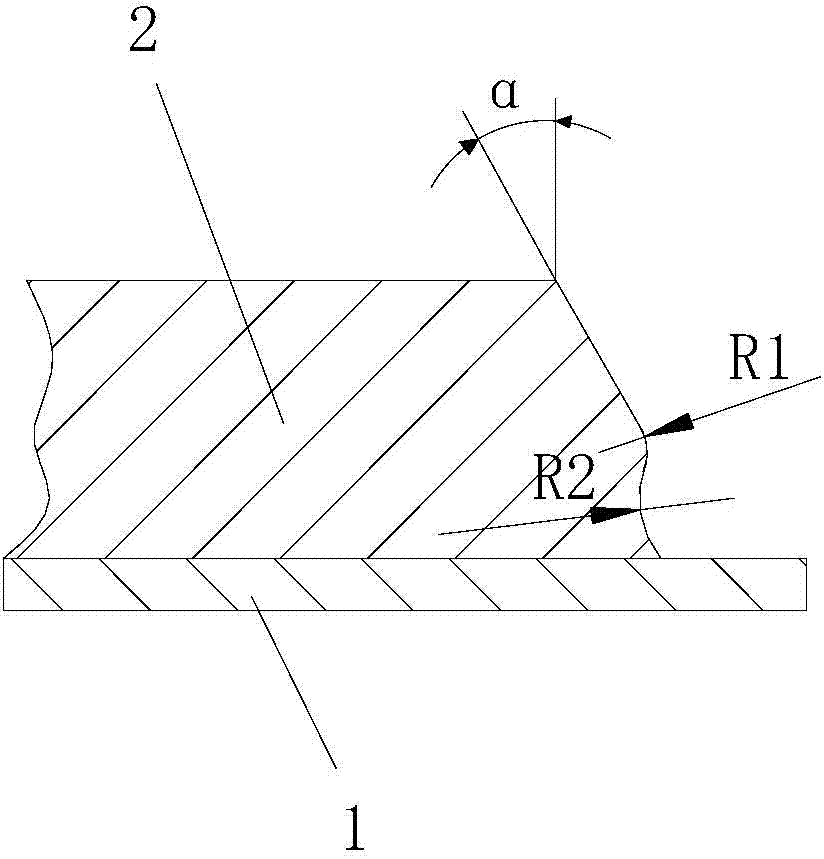

[0066] In this embodiment, the difference from Embodiment 1 is that the specification of the bimetal composite pipe to be sealed and welded is Φ114×(10+3) mm, and the material of the carbon steel base pipe 2 of the bimetal composite pipe to be sealed and welded is L360NS carbon steel and its wall thickness is 10mm, the material of the stainless steel lining pipe 1 of the bimetal composite pipe to be sealed and welded is 825 stainless steel and its wall thickness is 3mm, and the arc radius R2 of the arc section=2.5mm , the arc radius R1=3.5mm of the arc-shaped transition section, the height of the arc section is 4mm, α=30°; when root welding is performed in step 2, the welding current is 85A and the welding voltage is 16V When carrying out cover welding in step 3, welding current is 110A and welding voltage is 17V; When carrying out bottom welding in step 2 and carrying out cover welding in step 3, the stainless steel welding wire that adopts is 625 welding wire, wherein The di...

Embodiment 3

[0070] In this embodiment, the difference from Embodiment 1 is that the specification of the bimetallic composite pipe to be sealed and welded is Φ76×(7+2) mm, and the material of the carbon steel base pipe 2 of the bimetallic composite pipe to be sealed and welded is 20G carbon steel and its wall thickness is 7mm, the material of the stainless steel lining pipe 1 of the bimetal composite pipe to be sealed and welded is 316L stainless steel and its wall thickness is 2mm, the arc radius R2 of the arc section=2mm, The arc radius R1=3mm of the arc-shaped transition section, the height of the arc section is 3mm, α=20°; when performing bottom welding in step 2, the welding current is 70A and the welding voltage is 15V; the step When the cover welding is performed in the third step, the welding current is 90A and the welding voltage is 15V; when the bottom welding is performed in the step 2 and the cover welding is performed in the step 3, the stainless steel welding wire used is the...

Embodiment 4

[0074]In this embodiment, the difference from Embodiment 1 is that the specification of the bimetallic composite pipe to be sealed and welded is Φ168×(12.7+3) mm, and the material of the carbon steel base pipe 2 of the bimetallic composite pipe to be sealed and welded is 20G carbon steel and its wall thickness is 12.7mm, the material of the stainless steel lining pipe 1 of the bimetallic composite pipe to be sealed and welded is 316L stainless steel and its wall thickness is 3mm, α=35 °; carry out back welding in step 2 , the welding current is 90A and the welding voltage is 22V; when the cover welding is performed in step 3, the welding current is 110A and the welding voltage is 22V; The stainless steel welding wires are all stainless steel welding wire HS316L; the stainless steel welding wire HS316L contains the following chemical composition: 0.024%C, 1.57%Mn, 0.65%Si, 0.001%S, 0.015%P, 18.37%Cr, 11.36% Ni and 2.10% Mo, the balance is iron; the diameter of the stainless ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com