Automatic backwash filter for ballast water management system

A management system and backwashing technology, applied in fixed filter element filters, filtration and separation, chemical instruments and methods, etc., can solve the problem that it is difficult to meet the requirements for installation and use of ballast water systems, the amount of backwashing water is large, and the volume is large. and other problems, to achieve the effect of small footprint, large filter area and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in more detail below in conjunction with accompanying drawing example:

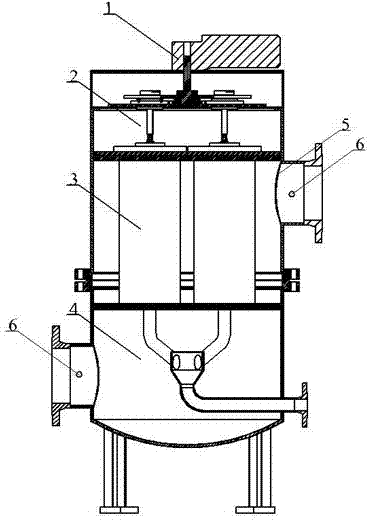

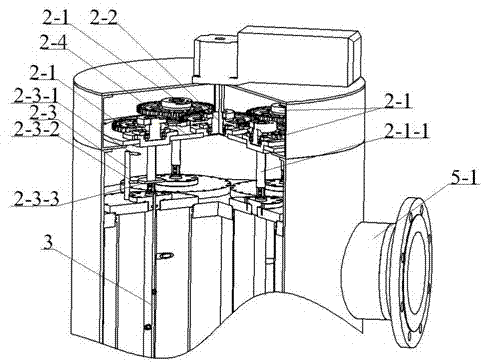

[0024] combine figure 1 , The automatic backwash filter of the present invention is composed of a cleaning motor 1 , a transmission assembly 2 , a filter assembly 3 , a lower cylinder assembly 4 , an upper cylinder assembly 5 and a differential pressure gauge 6 .

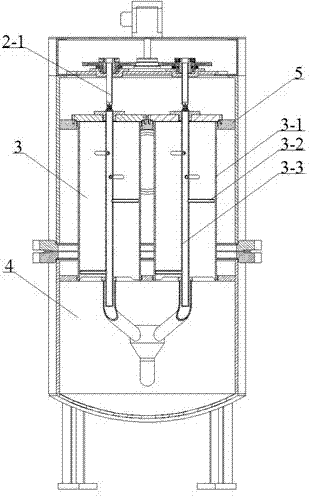

[0025] combine figure 2 , the filter assembly 3 is arranged between the lower cylinder assembly 4 and the upper cylinder assembly 5, and consists of four filter cartridges, each filter cartridge is provided with a filter screen 3-1, a filter nozzle 3-2 and a sewage shaft 3-3 The filter 3-2 is evenly arranged on the sewage shaft 3-3, and the inner hole of the filter 3-2 is connected with the inner hole of the sewage shaft 3-3; the number of the filter 3-2 can be four, 6, 8 pcs, 10 pcs, 12 pcs; the filter tip 3-2 is close to the filter screen 3-1, the distance value can be 3mm, 2mm, 1mm, 0mm, -1mm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com