Backwash spray nozzle for granular filter material filter device

A filter device and backwashing technology, which is applied in the direction of loose filter material filter, filter separation, gravity filter, etc., can solve the problem of affecting the use effect of granular filter material, the particle size of granular filter material becomes smaller, and sticks together and other problems, to achieve the effect of reducing maintenance workload, eliminating backwash dead angle, and reducing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

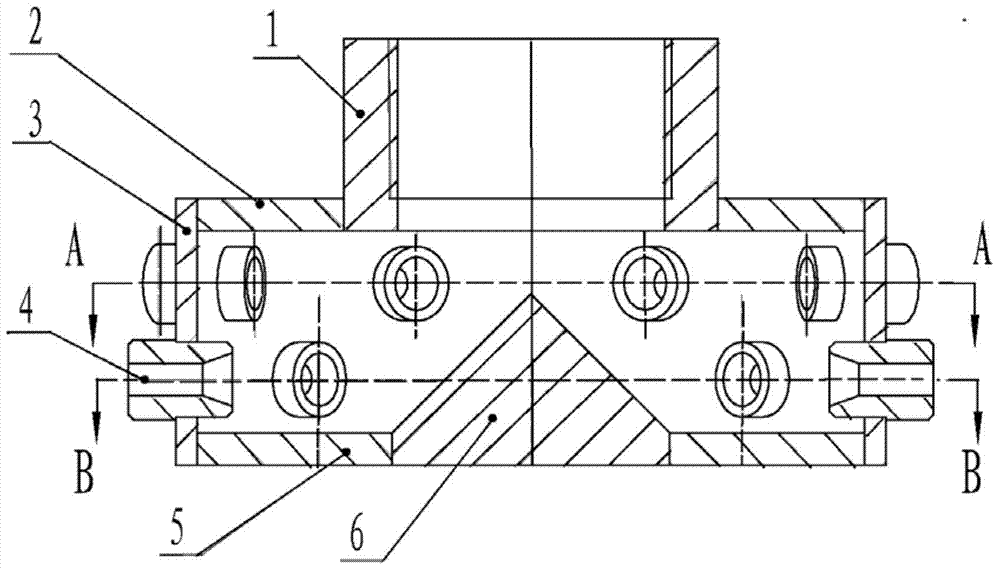

[0018] Embodiment 1: a kind of backwashing nozzle that is used for granular filter material filtering device provided by the present invention, its structure is as follows figure 1 As shown, it includes a connecting head 1, an upper ring 2, a cylindrical body 3, a spout 4, a bottom plate 5 and a cone head 6. One end of the cylindrical body 3 is provided with an upper ring 2, and the upper ring is connected with the connecting head 1. The other end of the cylinder body 3 is provided with a bottom plate 5, and the bottom plate is provided with a cone head 6, and the cylinder body 3 is provided with two rows of evenly arranged spouts 4;

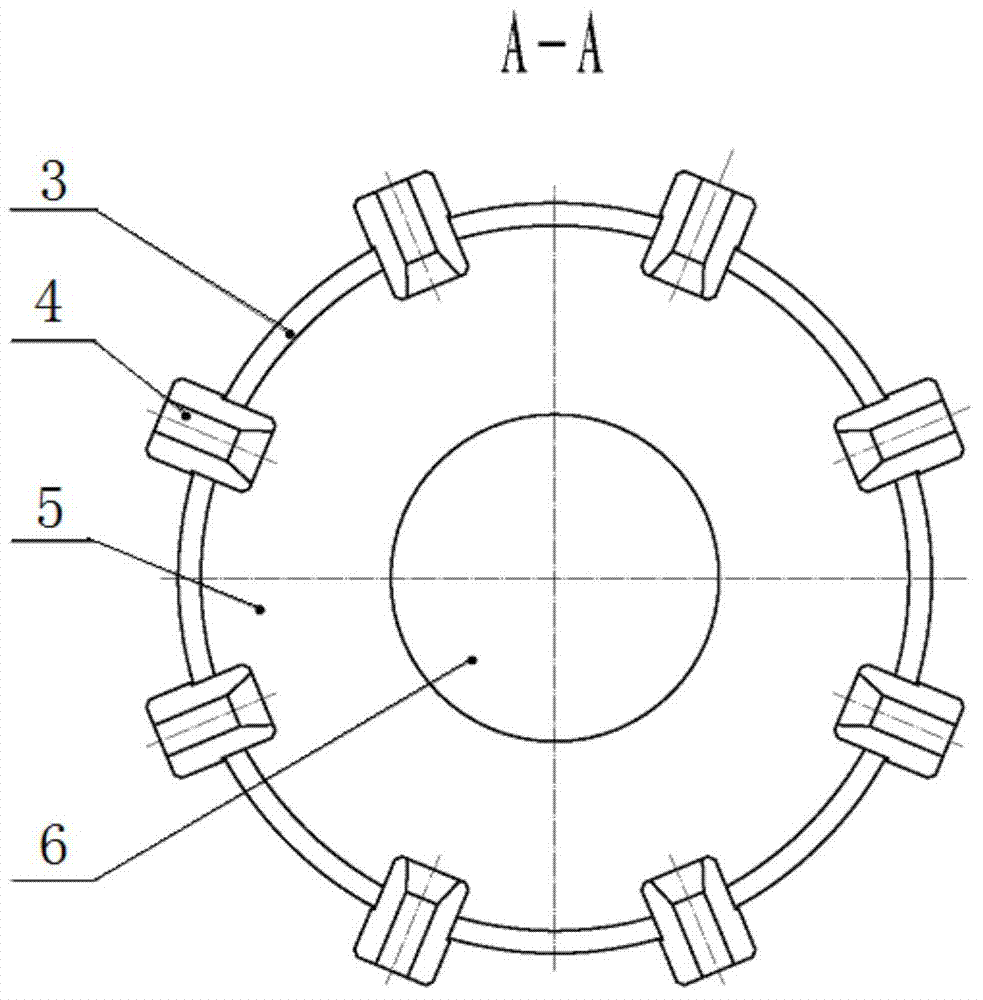

[0019] see figure 2 , 3 , the shape of the spout 4 of the nozzle of the present invention is cylindrical, the inner cavity of the spout is a combined structure of a trumpet tube and a straight circular tube, the spout 4 is installed on the wall of the cylinder 3, and the spout at the end of the cylinder 3 lumen The trumpet has a large mouth, ...

Embodiment 2

[0020] Embodiment 2: A kind of backwashing nozzle provided by the present invention, its structure is basically the same as that of Embodiment 1, the only difference is that only one row of nozzles 4 is arranged on the cylinder body 3, there are 18 nozzles in total, and the center of circle between the two nozzles The angles are equal, α=20°.

Embodiment 3

[0021] Embodiment 3: A kind of backwashing nozzle provided by the present invention, its structure is basically the same as Example 1, the difference is that three rows of nozzles are arranged on the cylinder, each row has 6 nozzles, and the central angles between the two nozzles are equal , α=60°, the first row of nozzles is aligned with the third row of nozzles, the second row of nozzles is misaligned with the first and third rows of nozzles, and the misalignment angle is 30°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com