Automatic peeling machine for white gourd

A technology of peeling machine and winter melon, which is applied in the fields of vegetable or fruit peeling, food science, application, etc. It can solve the problems of difficult cutting edge, inability to produce peeling effect, and reduced working efficiency of the whole machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

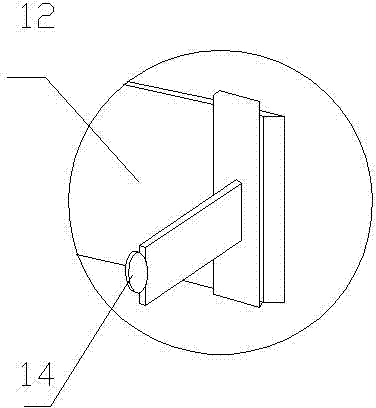

[0016] as attached figure 1 As shown, the wax gourd automatic peeling machine includes a frame 1, and the frame is provided with a clamping device that can drive the wax gourd to rotate freely. The thimble 3 is located on the axis of the turntable 2, and several fixed pins 4 are arranged on the surface of the turntable 2. The thimble 3 can move up and down through the top plate of the frame, and the thimble is locked by bolts as a locking device. During work, one end of the wax gourd sits on the turntable 2, and the other end is inserted by the thimble 3 on the top of the frame, and the wax gourd can rotate with the rotation of the turntable 2. In addition to the turntable and thimble-type clamping device structures listed in this embodiment, the clamping device can also adopt other structures, such as setting chucks that can move up and down at both e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com