Series gap arrester

A technology of series gap and arrester, applied in the direction of spark gap overvoltage arrester, spark gap, overvoltage protection resistor, etc., can solve the problem of affecting the service life of the arrester and the effect of discharging lightning current, poor corrosion resistance and aging resistance , insulator umbrella leaves burn and flash off and other problems, to achieve the effect of light weight, strong aging resistance and strong ultraviolet rays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

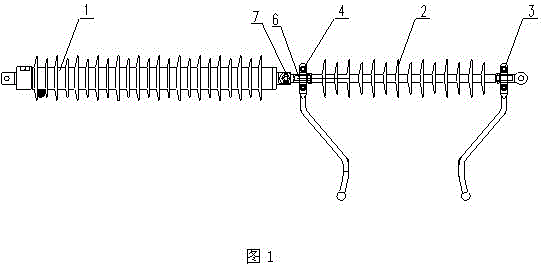

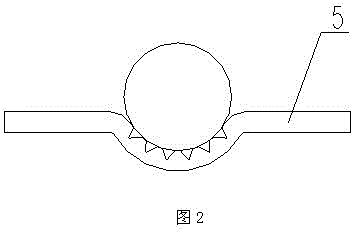

[0018] refer to figure 1 and figure 2 As shown, a series gap lightning arrester includes a lightning arrester main body 1, an insulator 2 arranged on the lightning arrester main body 1, an upper discharge rod 3 and a lower discharge rod 4 arranged at both ends of the insulator 2, the upper discharge rod 3 and the lower discharge rod 4 The discharge rods 4 are relatively arranged and an air gap is formed between the upper discharge rod 3 and the lower discharge rod 4; the gap between the upper discharge rod 3 and the lower discharge rod 4 is fixed on the insulator; the upper discharge rod and the lower discharge rod All are made of carbon fiber, high carbon graphite, copper powder, white steel powder and conductive resin; among them, the weight percentage of carbon fiber is 20%, the weight percentage of high carbon graphite is 40%, and the weight percentage of copper powder is 5%, white steel powder accounts for 5% by weight, and conductive resin accounts for 30% by weight; w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com