Trigger board connector for thyristor valve

A technology of thyristor valve and trigger board, which is applied in the direction of connection, two-part connection device, and parts of the connection device, etc., can solve the problems of small contact area between pins and jacks, poor electrical conductivity, and long connector terminals. , to achieve the effect of light weight, low contact resistance, long plug life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

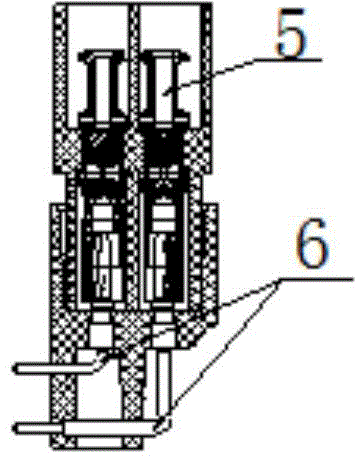

[0037] In this embodiment, the trigger board connector for a thyristor valve is taken as an example, such as Figure 1 to Figure 10 As shown, the thyristor valve trigger plate connector provided by the embodiment of the present invention includes: plug 1, socket 2, limit groove 3, long knurled captive screw 4, socket 5, pin 6, positioning hole 7, Fixing hole 8, trigger plate 9, wire 10, wire spring wire 11, test hole 12, test pin 13.

[0038] Both the plug 1 and the socket 2 are provided with chamfers at the entrance of the insulator, and are provided with a corresponding convex and concave limit groove 3. The limit groove 3 is a rectangle with a gap, which has a preliminary guiding effect on the connector and the plug 1 is inserted into the socket. 2. The anti-error function enables the plug 1 to enter the socket 2 smo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com