High-speed rotation testing machine and method for testing high-speed rotation strength performance of rotor

A high-speed rotating and testing rotor technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as easy resonance, and achieve large single-axis bearing capacity, stable operation, maintenance and installation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

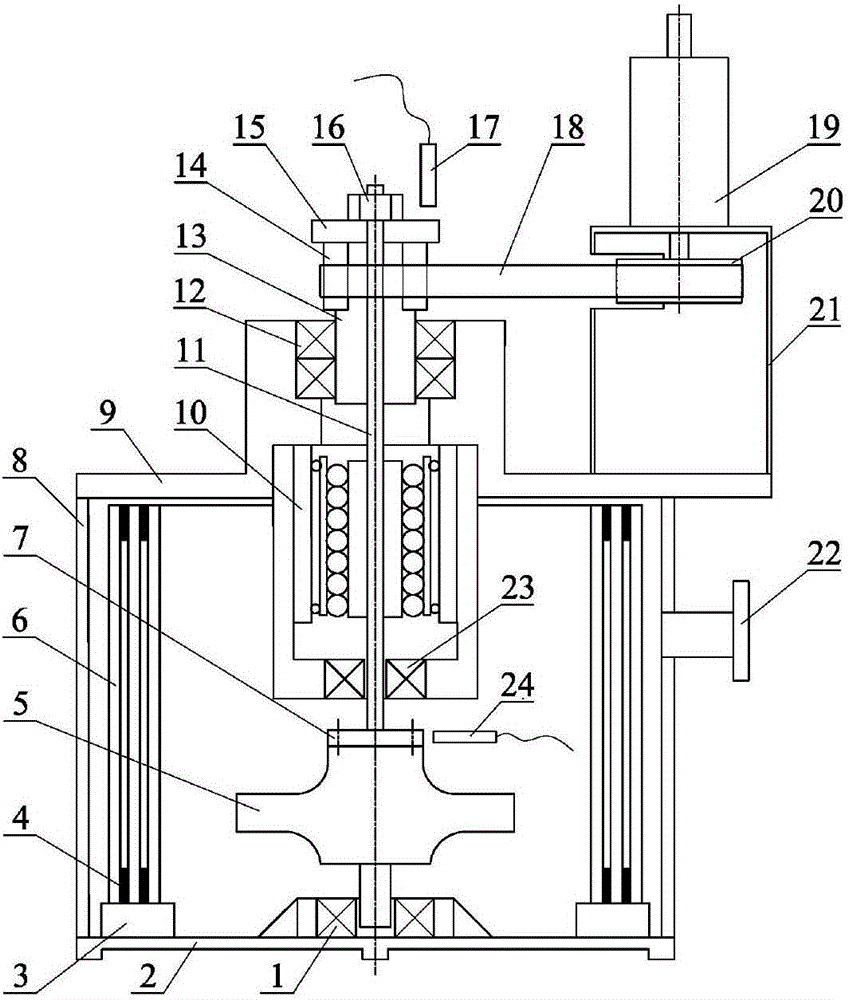

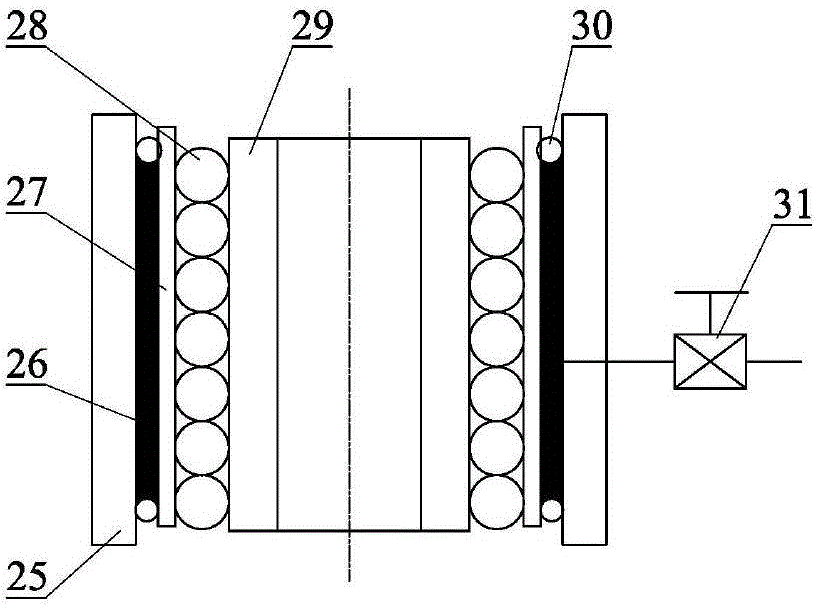

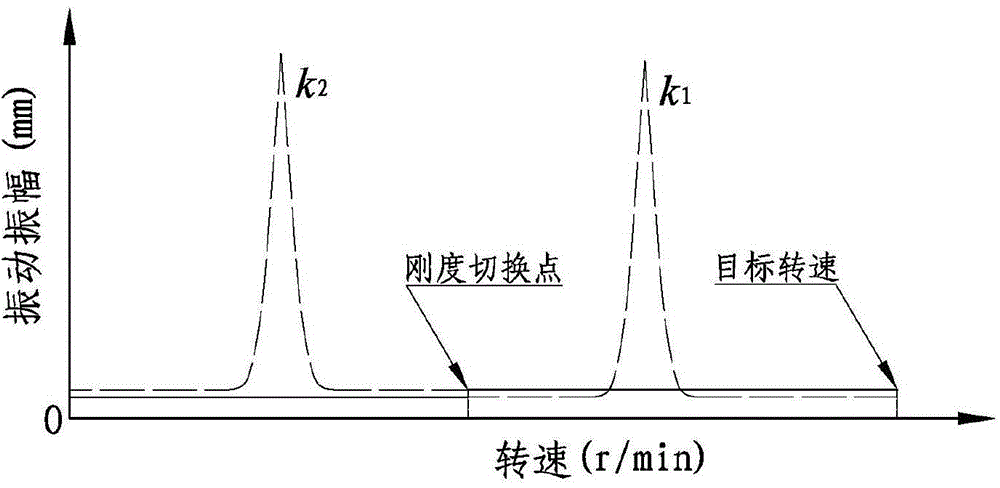

[0058] Such as figure 1 As shown, an inverted high-speed rotary testing machine includes a base plate 2, a test cavity 8 arranged on the base plate 2, a rotor system and a drive rotor accommodated in the test cavity 8 for the test rotor 5 to test The driving motor of the system, the speed increasing device connected with the driving motor and driving the rotor system to rotate, the safety protection device installed in the test chamber 8 and the speed control system for controlling the operation of the rotary testing machine. Wherein, the test cavity 8 is provided with a test cavity cover 9 and a vacuum port 22 , and the vacuum port 22 is connected with a vacuum pump for vacuuming the test cavity 8 . The driving motor is an inverted DC motor 19, the speed increasing device is a variable speed ratio speed increasing device, and the rotor system is an inverted high speed rotor system, which includes the test rotor fixing part 7; it is connected with the test rotor fixing part 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com