Casing coring drill and casing coring drilling method

A core drilling tool and casing technology, applied in the direction of extracting undisturbed core devices, drill bits, drilling equipment, etc., to achieve the effect of flexible and reliable convergence action, flexible and reliable convergence, and elimination of influencing factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

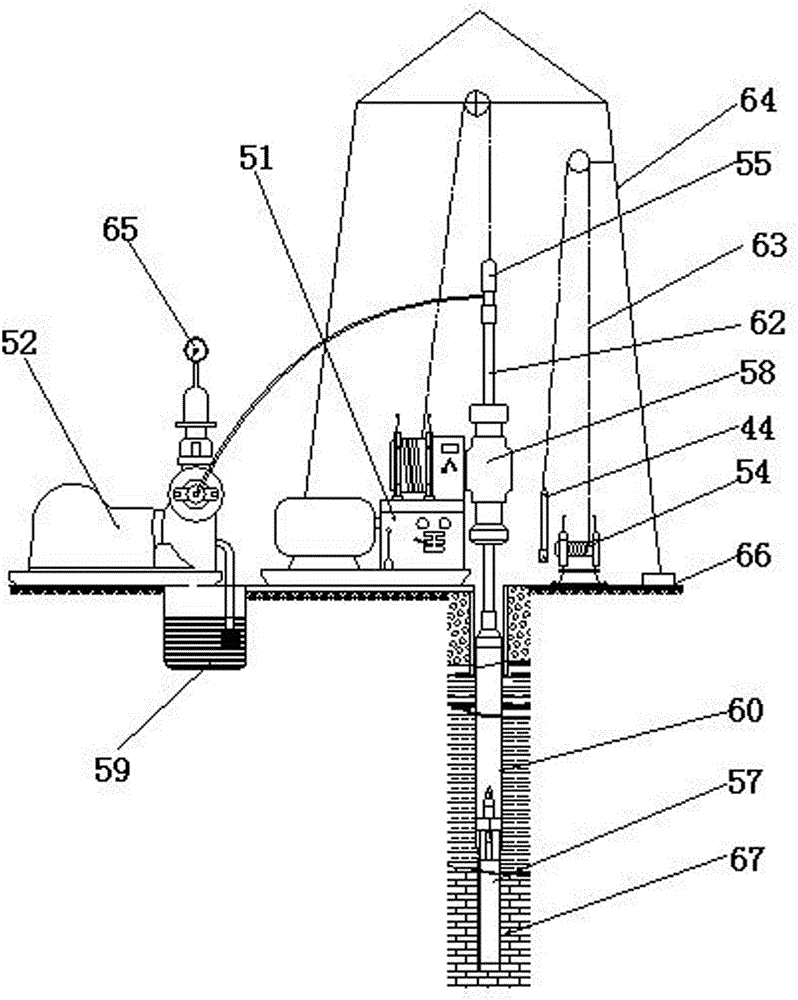

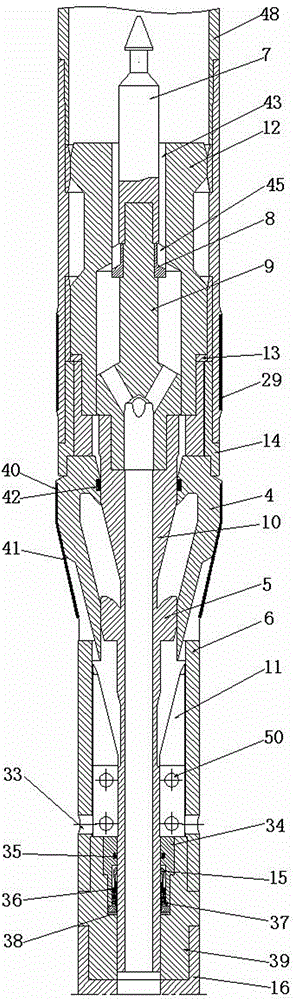

[0050] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, a casing coring drilling tool, the gyrator 58 of the core drilling machine 51 drives the upper drill rod 62 to rotate, drives the casing 56 in the hole instead of the drill rod to rotate, and drives the casing at the bottom of the hole in the working state of drilling. The core drilling tool 57 rotates; the drilling pressure applied by the core drilling machine 51 through its gyrator 58 is transmitted to the casing core drilling tool 57 at the bottom of the hole through the drill pipe 62 and casing 56 on the machine; the mud 59 from the mud pump 52 passes through the The casing is transported to the bottom of the hole, and the casing coring drill 57 performs coring drilling at the bottom of the hole. After the core containing pipe 17 is filled with the core 61, the drilling is stopped, and the casing is clamped by the orifice holder 53 56, the drill pipe ...

Embodiment 2

[0053]In this embodiment, on the basis of Embodiment 1, the upper cylindrical surface of the suspension joint 12 and the centralizing ring 24, and the double centralizing mechanism formed by the lower cylindrical surface of the suspension joint 12 and the sealing ring 26, make the inner pipe drilling tool 2 and the outer pipe drilling tool 1 Maintain a high coaxiality, and after the auxiliary drill bit 4 is opened, the casing core drilling tool has good rigidity, so that the drill tool can adopt a core containing tube with a length of more than 3 meters, and can operate at 400 rpm or more Normal drilling under the condition of a certain rotational speed; the lower part of the inner groove 32 of the bit frame 14 is provided with a sand discharge hole 33, and the cuttings ( Rock powder, gravel particles, sand, mud and other mixed solid phase substances) are excluded to prevent them from settling inside the drill bit frame, thereby eliminating the influence factors of cuttings sed...

Embodiment 3

[0055] Such as figure 1 , figure 2 , Figure 12 As shown, a casing coring drilling method, the ground device is a core drilling machine 51, a mud pump 52, an orifice holder 53, a winch 54, a rope fisher 44, and a puller 55, and the drilling device in the hole includes Casing coring tool 57 and casing 56; the casing 56 is used to replace the drill pipe and connected to the drill pipe 62 on the machine, and the core drilling machine 51 is used to drive the casing to rotate, and the casing coring tool 57 connected to the lower end of the casing is driven to carry out Coring drilling; the mud pump 52 sends the mud 59 to the hole through the inner cavity of the casing to cool the drilling tool, carry the rock powder and maintain the stability of the hole wall; The overshot 44 lifts the inner pipe drilling tool of the casing core drilling tool 57 in the hole to the ground 66, while taking the rock core 61, checks or replaces the service drill bit at the bottom of the hole, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com