Assembled tooth-shaped laminated floor

A superimposed floor slab and assembled technology, applied in the direction of floor slabs, building components, buildings, etc., can solve problems such as misalignment and cracks, and achieve the effects of reducing poor deformation, not easy to move, and high rigidity of the slab.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the embodiments shown in the accompanying drawings.

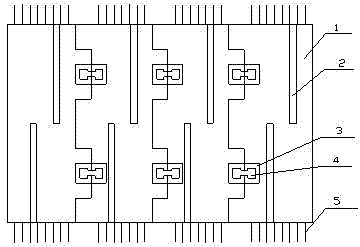

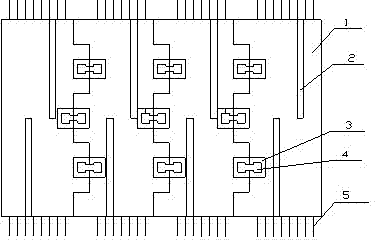

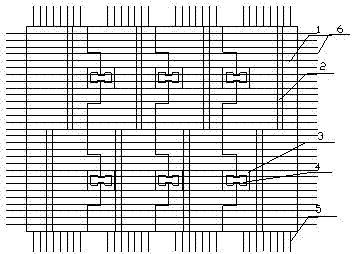

[0026] The present invention has two forms, one is a rectangular tooth superimposed floor slab with a latch, and the other is a trapezoidal tooth superimposed floor without a latch. It is mainly composed of the following parts: bottom plate 1, segmented rib 2, latch groove 3, latch 4, lower longitudinal reinforcement 5, lower horizontal reinforcement 6, rectangular teeth 7, rectangular slots 8, trapezoidal teeth 9, trapezoidal slots 10.

[0027] The bottom plate 1 is wrapped with the lower longitudinal steel bar 5, on which there are two segmented ribs 2, and the longitudinal edge of the plate is set in a tooth shape. Latch groove 3 is set at the bottom plate, segmented rib 2, latch groove 3, bottom longitudinal steel bar 5, rectangular teeth 7, trapezoidal teeth 9, rectangular tooth grooves 8, trapezoidal tooth grooves 10 and other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com