Method for production of chemical raw materials by comprehensive utilization of lithium slag

A technology of chemical raw materials and lithium slag, applied in chemical instruments and methods, ammonium halide, silicon oxide, etc., can solve the problems of poor chemical composition, reduced economic benefits, complicated process, etc., to promote comprehensive utilization of decomposition, improve The effect of economic benefits and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

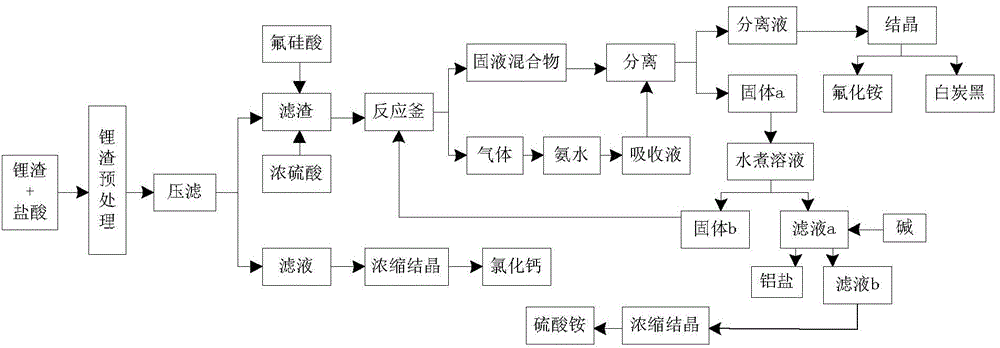

Image

Examples

Embodiment 1

[0028] Put 1g of lithium residue into the reaction kettle and dissolve it with 0.3ml of hydrochloric acid with a concentration of 11% by mass. After reacting for 0.2h, a reaction mixture was obtained. The mixture was washed with water and separated by pressure filtration to obtain a filter residue and a filtrate. Concentrate and crystallize the filtrate to obtain calcium chloride. Then, react the filter residue with 4.5ml of 25% fluosilicic acid and 0.15ml of concentrated sulfuric acid in a reaction kettle at a temperature of 110°C and 2atm for 3h. Absorb the generated gas with ammonia water with a concentration of 25% by mass, and separate the absorption liquid from the reaction mixture in the reactor to obtain solid a and separation liquid, and then crystallize the separation liquid to obtain ammonium fluoride and white carbon black . The solid a product was boiled and dissolved for 25 minutes, and then separated to obtain solid b and filtrate a, and then solid b was return...

Embodiment 2

[0030] Put 1g of lithium slag into the reaction kettle and dissolve it with 0.5ml of hydrochloric acid with a concentration of 11% by mass. After reacting for 0.5h, a reaction mixture was obtained. The mixture was washed with water and separated by pressure filtration to obtain a filter residue and a filtrate. Concentrate and crystallize the filtrate to obtain calcium chloride. Then, react the filter residue with 5ml of 15% fluosilicic acid by mass and 0.3ml of concentrated sulfuric acid in a reaction kettle at a temperature of 100°C and 2atm for 1.5h. Absorb the generated gas with ammonia water with a concentration of 15% by mass, and separate the absorption liquid from the reaction mixture in the reactor to obtain solid a and separation liquid, and then crystallize the separation liquid to obtain ammonium fluoride and white carbon black . The solid a product was boiled and dissolved for 20 minutes, and then separated to obtain solid b and filtrate a, and then solid b was re...

Embodiment 3

[0032] Put 1000g of lithium slag into the reaction kettle and dissolve it with 200ml of hydrochloric acid with a concentration of 15% by mass. After reacting for 0.5h, a reaction mixture was obtained. The mixture was washed with water and separated by pressure filtration to obtain a filter residue and a filtrate. Concentrate and crystallize the filtrate to obtain calcium chloride. Then, react the filter residue with 2000ml of 35% fluosilicic acid and 100ml of concentrated sulfuric acid in a reaction kettle at a temperature of 110°C and 2atm for 1.5h. Absorb the generated gas with ammonia water with a concentration of 25% by mass, and separate the absorption liquid from the reaction mixture in the reactor to obtain solid a and separation liquid, and then crystallize the separation liquid to obtain ammonium fluoride and white carbon black . The solid a product was boiled and dissolved for 30 minutes, and then separated to obtain solid b and filtrate a, and then solid b was retu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com