A tube extruding die and its preparation of special-shaped conductor cables

A conductor cable, special-shaped technology, applied in the direction of conductor/cable insulation, conductor, insulated conductor, etc., can solve the problem that the single wire is easy to be broken or pulled, the strand is easy to be scattered, and the take-up reel is easy to be scattered, etc. problems, to achieve the effect of reducing the total cost of the cable, avoiding the phenomenon of scattering, saving filling materials and sheath materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

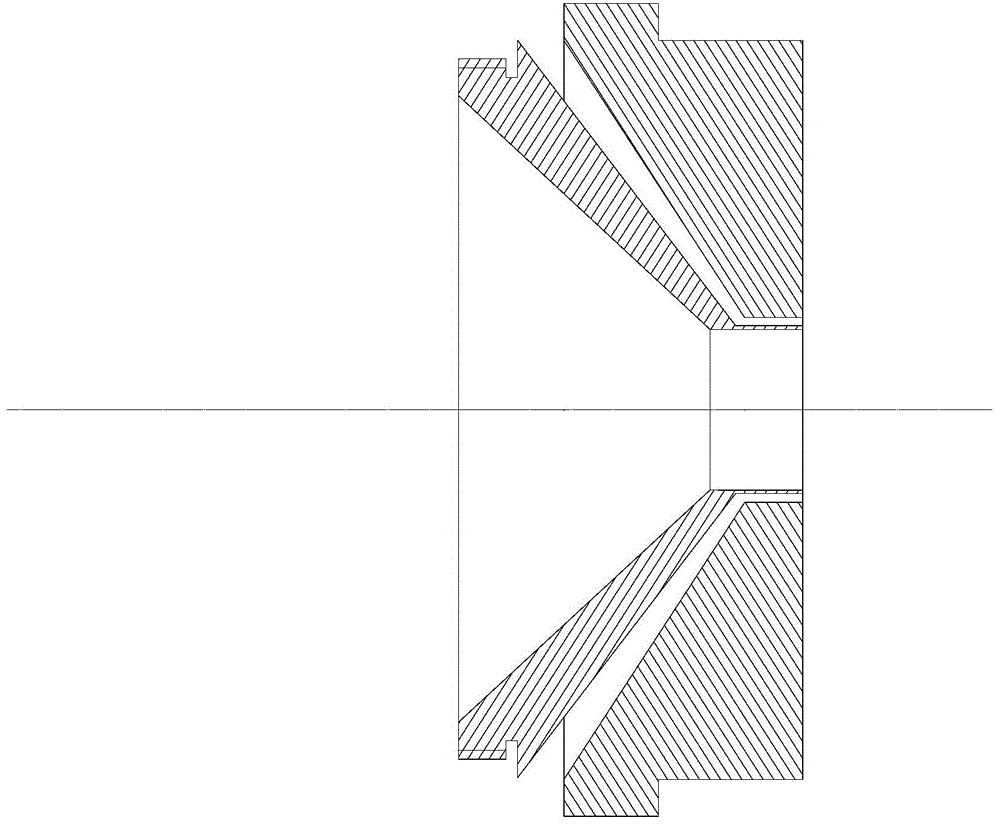

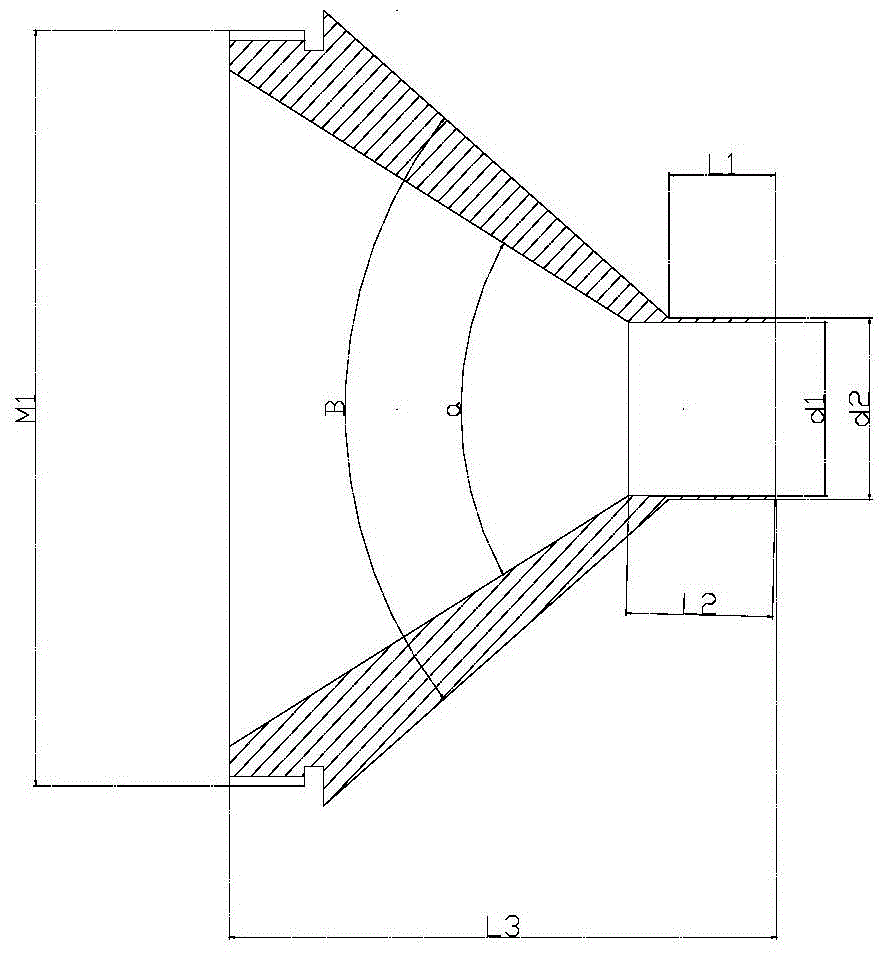

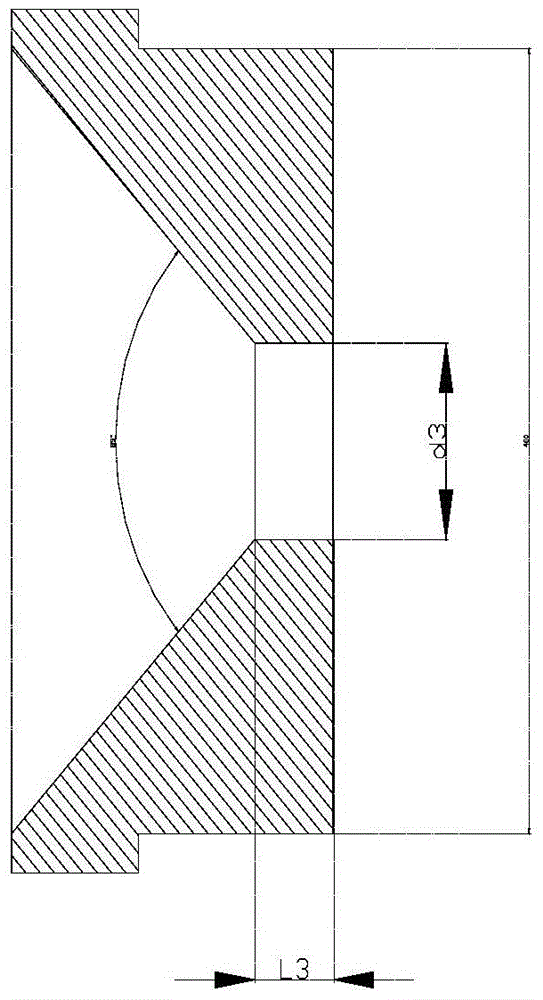

[0036] Please refer to figure 1 , 2 , 3, 4, 5, the size of the core structure is limited by factors such as the diameter of the core sizing area, the diameter of the outer cylinder of the core sizing area, the length of the outer cylinder of the core sizing area, and the length of the cylinder in the sizing area. The diameter d1 in the core sizing area is designed according to the wear resistance of the selected material, the size of the semi-product (wire core or cable core), its material and the degree of regularity of the outer diameter, etc. The general design is: when insulating, d1=d 线芯 +(2~3)mm; when sheathed, d1=d 线芯 +(3~7)mm. Usually, when designing mold specifications, serialization should be considered, and the mold size should be adjusted to an integer; the diameter d2 of the outer cylinder of the core sizing area is determined by d1 and its wall thickness, that is, d2=d1+2, the design of this wall thickness is not only To take into account the life of the mold ...

Embodiment 2

[0041] 1) Selection of molds

[0042]The five types of special-shaped conductors adopt a designed extrusion die with a circular die core and a circular die sleeve when using plastic insulation. When the five types of special-shaped conductors are insulated with rubber, the die core is a circular die sleeve and the die sleeve is an oval extruded tube die sleeve.

[0043] 2) Adjust the conductor pressing wheel to the preset angle, press the five types of conductor 1 to the required angle (such as 90 ° C, 120 ° C, etc.), and then use polyester film 2 for non-overlapping 50% gap wrapping , which results in figure 1 The five types of shaped conductors shown.

[0044] 3) Cable

[0045] Improve the cabling die and runner of the insulated core, pre-twist in advance according to experience, and maximize the insulation thickness of the arc edge covered on the special-shaped conductor to be close to the calculated value, so as to obtain the smallest cabling and finished product outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com