Waterproof material, waterproof fiberboard, laminated wood floor, production method of waterproof fiberboard, and production method of laminated wood floor

A technology for laminate flooring and waterproof material, which is applied in the production field of waterproof material, fiberboard and laminate flooring, can solve the problems affecting the waterproof performance of the floor, the penetration of high melting point paraffin, poor sealing and adhesion performance, etc. The effect of improving the usability and improving the waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

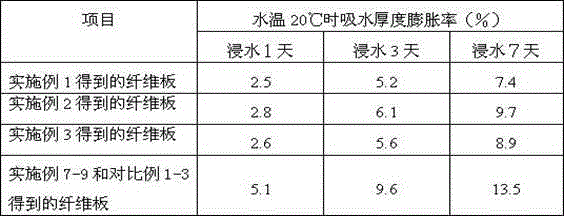

Examples

Embodiment 1

[0024] Embodiment 1: When making fiberboard according to the prior art, carry out the following improvements: 100 parts by weight of paraffin wax with a melting point of 50° C. is added in the wax melting tank, and after the paraffin wax is melted, slowly add a particle size of nano-scale hydrophobic two under stirring conditions. 10 parts by weight of silicon oxide, after uniform dispersion, heat preservation at 130°C for 40 minutes to remove the water-absorbing groups in the paraffin-hydrophobic silica mixture to obtain a fiberboard waterproof material, press the prepared fiberboard waterproof material The proportion of 1wt% is dripped or pumped into the heat refiner for fiberboard production.

[0025] When making laminate flooring according to the existing technology, the following improvements are made: 100 parts by weight of paraffin wax with a melting point of 45°C is added to the wax melting tank, and after the paraffin wax is melted, slowly add hydrophobic silicon dioxi...

Embodiment 2

[0026] Embodiment 2: When making fiberboard according to the prior art, carry out the following improvements: 100 parts by weight of paraffin wax with a melting point of 58° C. is added in a wax melting tank, and after the paraffin wax is melted, slowly add a particle size of micron-sized hydrophobic disulfide under stirring conditions. 3 parts by weight of silicon oxide, evenly dispersed, and kept at 140°C for 25 minutes to remove the water-absorbing groups in the paraffin-hydrophobic silica mixture to obtain a fiberboard waterproof material. The proportion of 2wt% is dripped or pumped into the heat refiner for fiberboard production.

[0027] When making laminate flooring according to the existing technology, the following improvements are made: 100 parts by weight of paraffin wax with a melting point of 50°C is added to the wax melting tank, and after the paraffin wax melts, slowly add hydrophobic silica with a particle size of micron size under stirring conditions 1 part by...

Embodiment 3

[0028] Embodiment 3: When making fiberboard according to the prior art, carry out the following improvements: 100 parts by weight of paraffin wax with a melting point of 54° C. is added in a wax melting tank, and after the paraffin wax is melted, slowly add a particle size of nano-scale hydrophobic two under stirring conditions. 7 parts by weight of silicon oxide, after uniform dispersion, heat preservation at 145°C for 20 minutes to remove the water-absorbing groups in the paraffin-hydrophobic silica mixture to obtain a fiberboard waterproof material, and press the prepared fiberboard waterproof material into dry fiber The proportion of 1.5wt% is dripped or pumped into the heat refiner for fiberboard production.

[0029] When making laminate flooring according to the prior art, the following improvements are made: add 100 parts by weight of paraffin wax with a melting point of 55°C into the wax melting tank, and after the paraffin wax melts, slowly add hydrophobic silica with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com