High-efficiency tree peeling machine

A technology of peeling machines and trees, applied in the direction of bark, wood processing equipment, manufacturing tools, etc., can solve the problem that the equipment is difficult to achieve automatic feeding, automatically adjust the cutting depth of the feeding space, the equipment is limited in use, and consumes a lot of manpower and material resources. and other problems to achieve the effect of improving processing quality, realizing adjustability and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

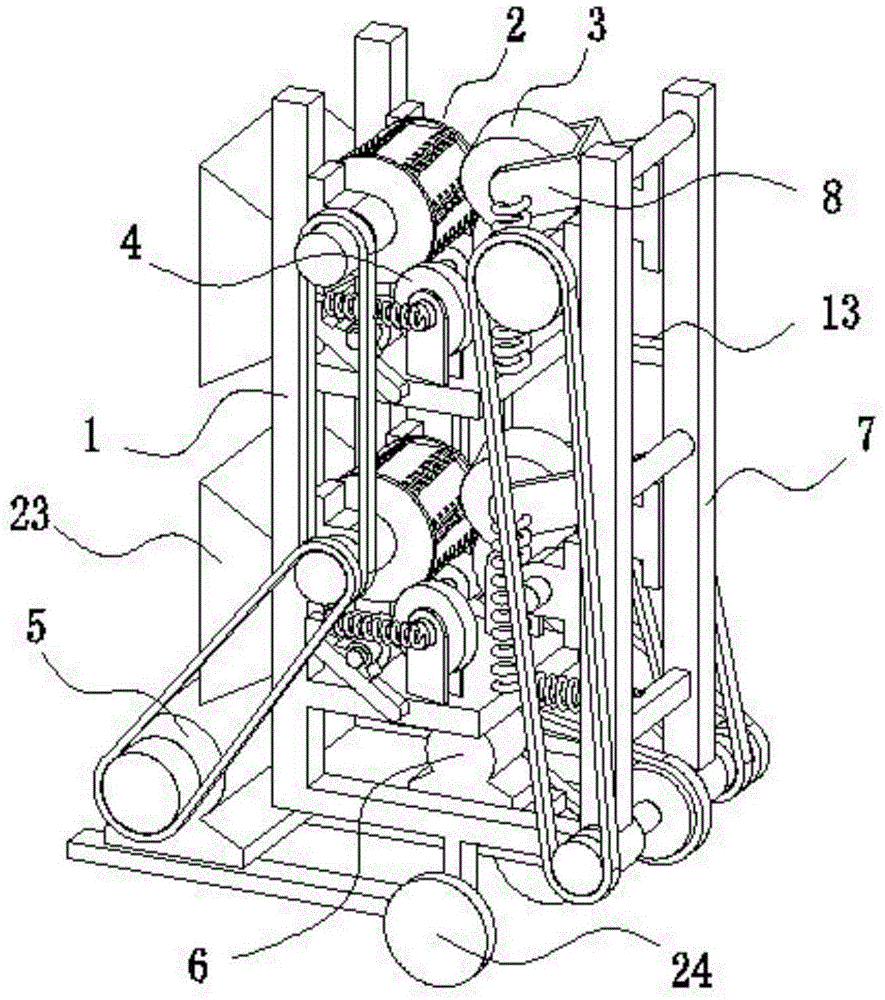

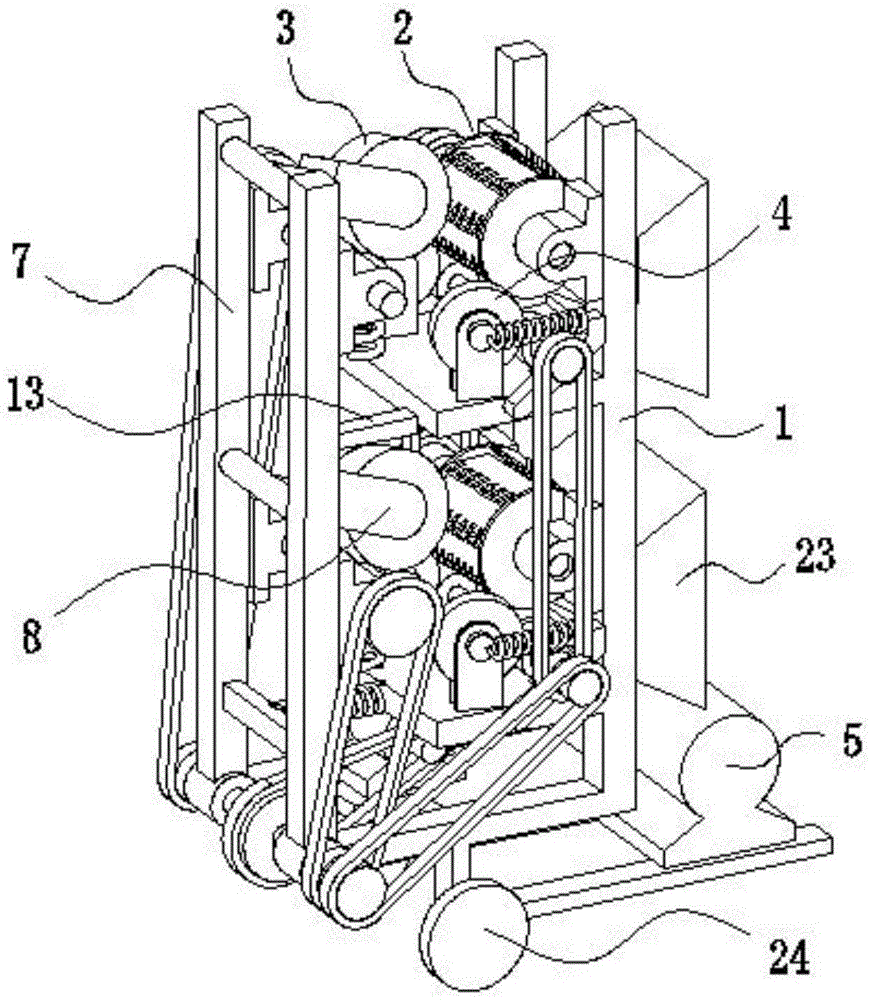

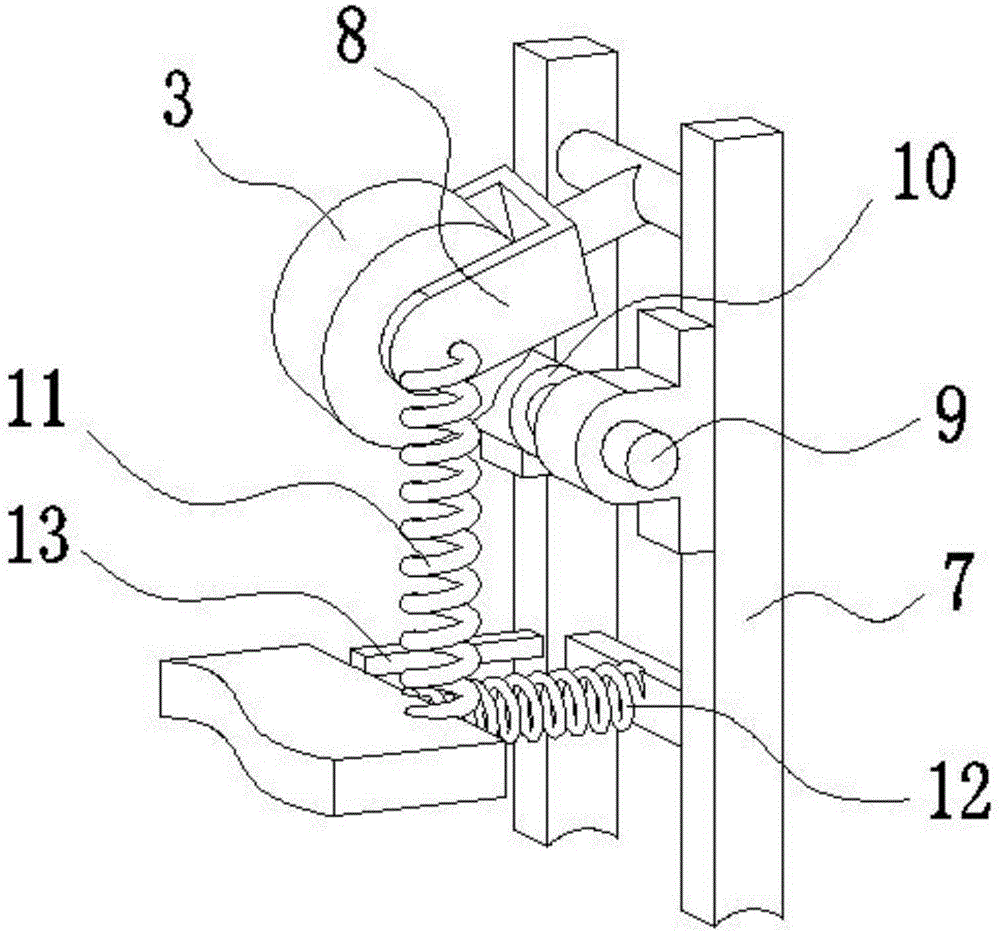

[0023] The present invention is described below in conjunction with accompanying drawing.

[0024] Such as Figure 1-5 As shown, a kind of high-efficiency tree peeling machine of the present invention comprises frame 1, driving device and two groups of cutting and feeding assemblies that are arranged up and down; The rear portion of described frame 1 is provided with rotatable rear frame 7; Each group of described cutting feeding assembly comprises cutterhead assembly 2, upper feeding wheel 3, lower feeding wheel 4, upper feeding wheel connecting arm 8, upper wheel shaft 9, lower connecting arm 14 and lower wheel shaft 15; 2 includes a blade 18, a cutter shaft disk 19 and a limit disk 20; the cutter shaft disk 19 is rotatably arranged on the frame 1, and the axis of the cutter shaft disk 19 is parallel to the feeding direction; the blade 18 has a plurality of , a plurality of blades 18 are obliquely and evenly arranged on the outer circumference of the cutter shaft disc 19; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com