Uncoiling and blanking method

An uncoiling, blanking, and coiling technology, applied in auxiliary devices, laser welding equipment, auxiliary welding equipment, etc., can solve the problems affecting the continuous production of the system, small-area scrap falling, unavoidable indirect cutting contact, etc. Simplified line layout, easy manipulation, and flexible working methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

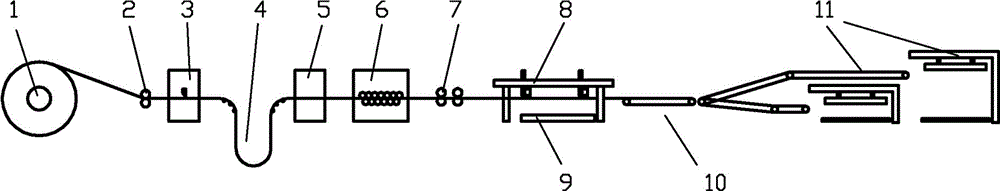

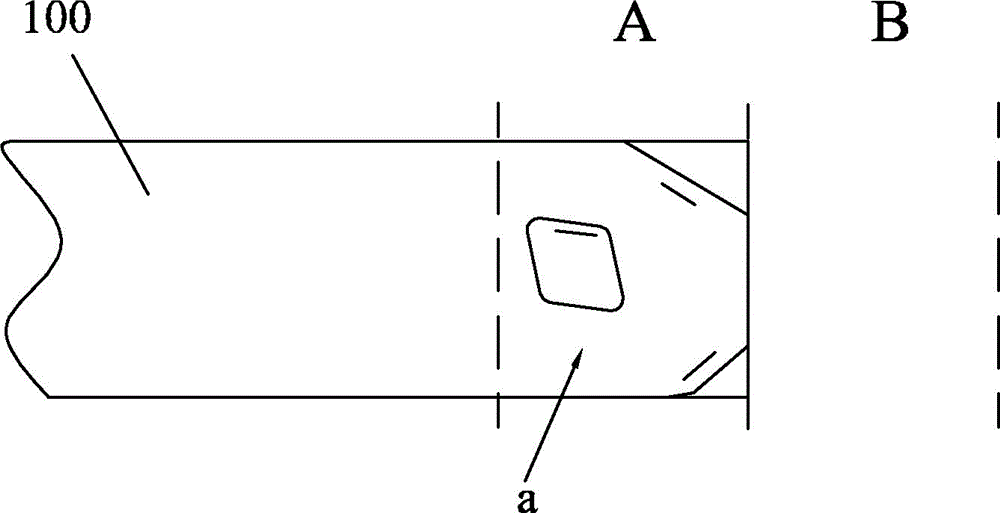

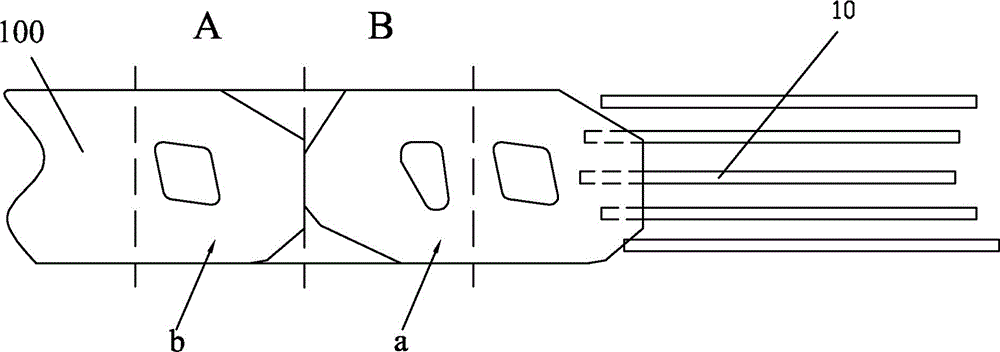

[0020] See figure 1 , An uncoiling blanking method of the present invention, unwinding 1, straightening 2, and cutting head 3 into the looper 4, after the looper 4, the surface of the roll is cleaned 5, leveled 6 and then pinched The rod 7 enters the laser cutting blanking 8. The laser cutting adopts a static double laser cutting head to cut the tape roll. The cutting waste falls in the cutting area and is sent out. After the cutting is completed, the obtained sheet is cut off by the material receiving device. 10 After receiving the material, it is conveyed to the picking and stacking area by the conveyor belt, and the sheet material is stacked by the sheet material picking and stacking device 11.

[0021] In this embodiment, the sheet stack is provided with two stacking positions, one stacking position and two stacking positions.

[0022] In this embodiment, the waste material in the cutting area is dropped and sent out in a manner that the waste material falls into the lateral wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com