A method for locating the position of railway line sleepers

A technology for railway lines and positioning methods, which is applied to roads, tracks, track maintenance, etc., can solve the problems of large operation errors, unstable operation status, and low degree of automation, and achieves small operation errors, no manual intervention, and high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

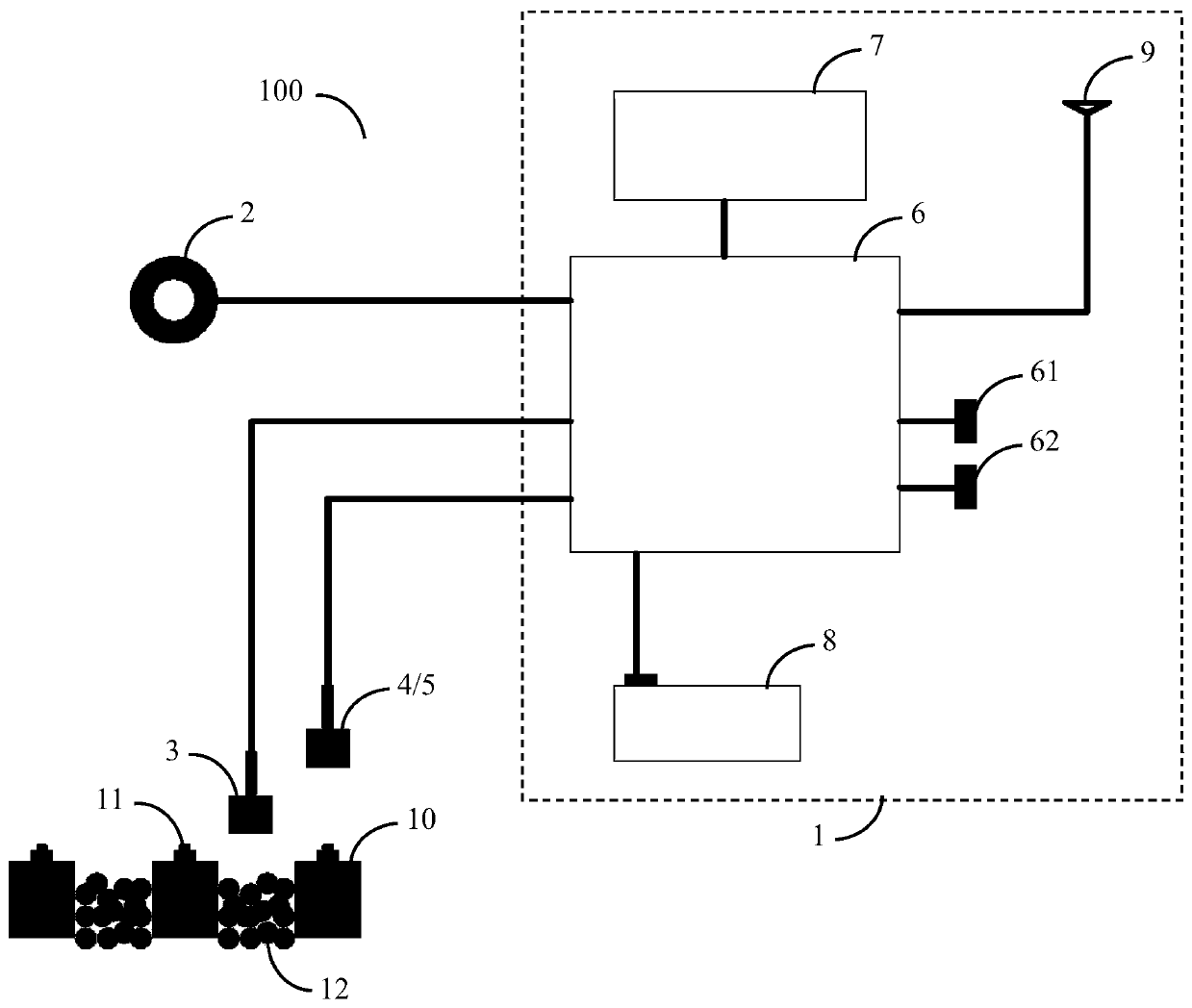

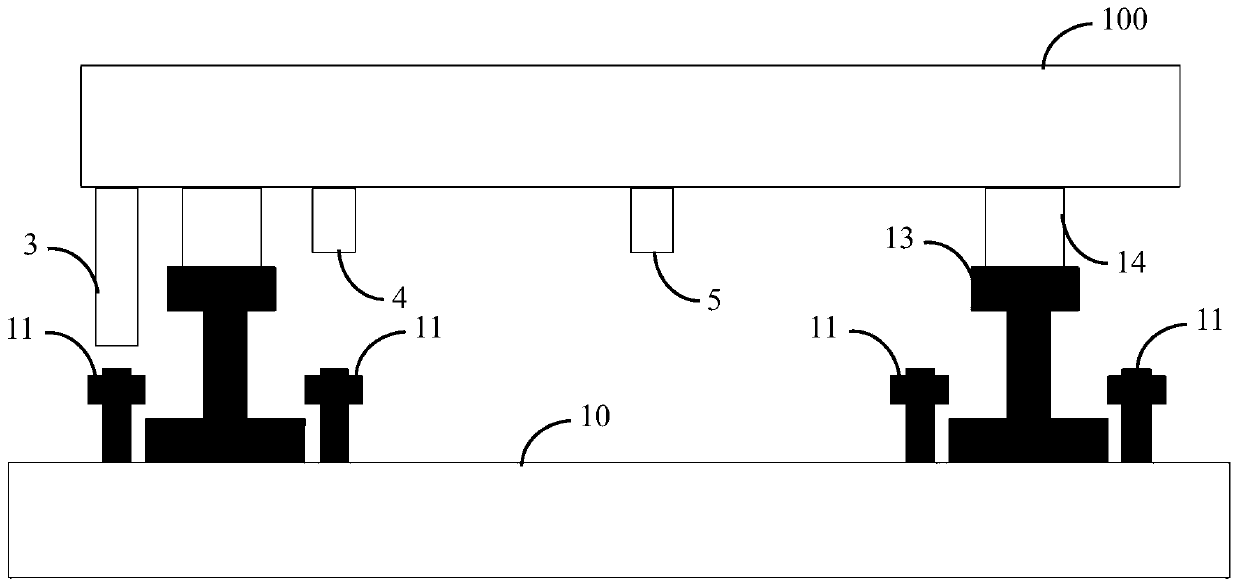

[0043] as attached figure 1 And attached figure 2 As shown, a specific embodiment of the railway line sleeper position measuring device based on the method of the present invention includes:

[0044] Measurement module 1;

[0045] The measuring wheel 2 connected with the measuring module 1 is used to measure the mileage of the railway line;

[0046] The magnet induction switch 3 connected with the measurement module 1 is used to detect the spike 11 on the sleeper 10;

[0047] The first distance proximity switch 4 connected with the measurement module 1 is used to detect the spike 11 on the sleeper 10;

[0048] The second distance proximity switch 5 connected with the measuring module 1 is used for detecting the sleeper 10 .

[0049] The railway line sleeper position measuring device 100 is placed (supported by the wheel set 14) on the rail 13, the magnetic induction switch 3 measures the spike 11 on the sleeper 10, the first distance proximity switch 4 measures the spike ...

Embodiment 2

[0060] as attached Figure 7 As shown, a specific embodiment of the railway line sleeper position positioning method of the present invention comprises the following steps:

[0061] S101) When located at the starting point of the railway line, the railway line sleeper position measuring device 100 will mark the kilometer to the starting point;

[0062] S102) The railway line sleeper position measuring device 100 begins to measure along the railway line, and the kilometer mark moves forward. When the sleeper 10 is detected, the center position of the sleeper 10 is marked, and the corresponding kilometer mark is marked;

[0063] S103) When it is detected that there is an obstacle 16 between the sleepers 10, an obstacle mark is marked between the two sleepers 10, and a corresponding kilometer mark is marked;

[0064] S104) When it is detected that there is a joint 17 between the two rails 13, a rail joint mark is marked between the corresponding two sleepers 10, and the correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com