Automotive frame fold straightening machine

A technology of automobile girders and straightening machines, which is applied in the field of auto repair machinery and equipment, can solve problems such as unreasonable design of the rotating connection lug plate and hook structure, difficult repair of automobile girders, and low safety factor of operators, so as to simplify manual intervention Strong strength, strong flexibility in repair operation, and the effect of ensuring the same rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

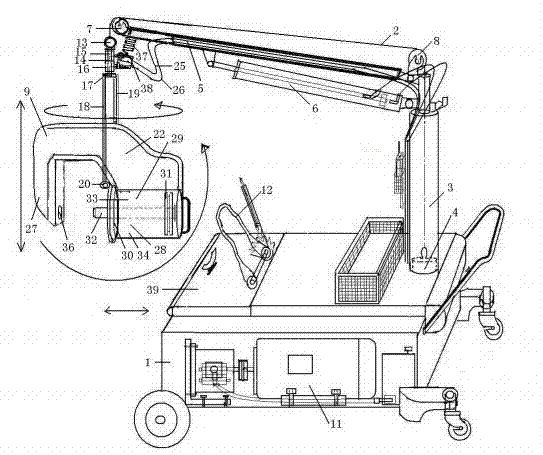

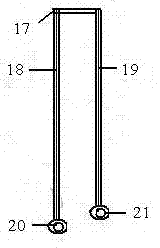

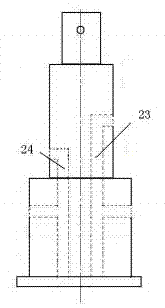

[0034] An automobile girder fold straightening machine, comprising a car body 1, a steel rope 2, a column 3 installed at the rear end of the vehicle body 1, a counterweight 4 installed in the column 3, a rotating bracket 5 installed on the column 3, an installation The adjustment oil cylinder 6 on the rotating bracket 5, the front fixed pulley 7 installed on the front end of the rotating bracket 5 and the rear fixed pulley 8 at the rear end also include an omni-directional rotation straightening device 9 capable of rotating 360 degrees horizontally and vertically. , the remote control receiver 10 installed in the car body 1 for controlling the omnidirectional rotary straightening device 9 and the motor oil pump unit 11 that provides power for the omnidirectional rotary straightening device 9 through oil pipes, the motor oil pump group 11 and the remote control receiver 10 is electrically connected, the omni-directional rotating straightening device 9 is connected to one end of ...

Embodiment 2

[0037] An automobile girder fold straightening machine, comprising a car body 1, a steel rope 2, a column 3 installed at the rear end of the vehicle body 1, a counterweight 4 installed in the column 3, a rotating bracket 5 installed on the column 3, an installation The adjustment oil cylinder 6 on the rotating bracket 5, the front fixed pulley 7 installed on the front end of the rotating bracket 5 and the rear fixed pulley 8 at the rear end also include an omni-directional rotation straightening device 9 capable of rotating 360 degrees horizontally and vertically. , the remote control receiver 10 installed in the car body 1 for controlling the omnidirectional rotary straightening device 9 and the motor oil pump unit 11 that provides power for the omnidirectional rotary straightening device 9 through oil pipes, the motor oil pump group 11 and the remote control receiver 10 is electrically connected, the omni-directional rotating straightening device 9 is connected to one end of ...

Embodiment 3

[0040]An automobile girder fold straightening machine, comprising a car body 1, a steel rope 2, a column 3 installed at the rear end of the vehicle body 1, a counterweight 4 installed in the column 3, a rotating bracket 5 installed on the column 3, an installation The adjustment oil cylinder 6 on the rotating bracket 5, the front fixed pulley 7 installed on the front end of the rotating bracket 5 and the rear fixed pulley 8 at the rear end also include an omni-directional rotation straightening device 9 capable of rotating 360 degrees horizontally and vertically. , the remote control receiver 10 installed in the car body 1 for controlling the omnidirectional rotary straightening device 9 and the motor oil pump unit 11 that provides power for the omnidirectional rotary straightening device 9 through oil pipes, the motor oil pump group 11 and the remote control receiver 10 is electrically connected, the omni-directional rotating straightening device 9 is connected to one end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com