360 degree pneumatic cleaning purger

A purging device and cleaning brush technology, applied in the direction of cleaning methods, cleaning methods and appliances, chemical instruments and methods using gas flow, etc., can solve the problems of insulators not being able to clean 360 degrees, high-voltage insulation safety hazards, and stable operation of the power grid. and other problems to achieve the effect of eliminating hidden dangers of insulation, light weight and small inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

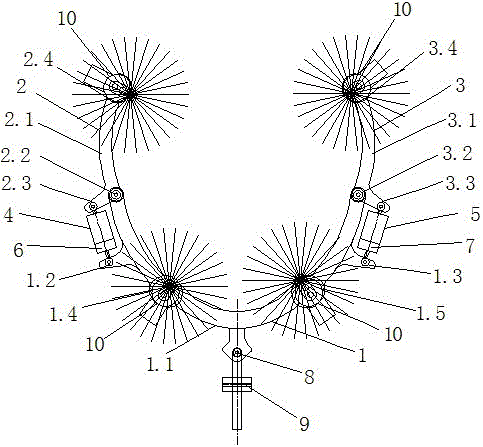

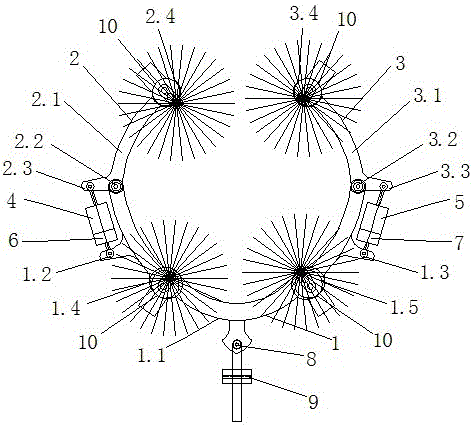

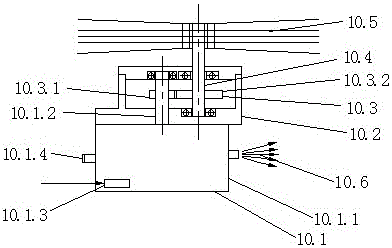

[0029] Such as figure 1 , figure 2 As shown, the 360-degree pneumatic cleaning purger includes: a fixed frame 1, a left movable mechanical arm 2 and a right movable mechanical arm 3, a left cylinder 4 and a right cylinder 5, a left pneumatic solenoid valve 6 and a right pneumatic solenoid valve 7, Horizontal angler 8, vertical angler 9 and four pneumatic sweeping brushes 10.

[0030] The fixed frame 1 includes a fixed frame 1.1, a cylinder connecting frame 1.2, a cylinder connecting frame 1.3, a cleaning brush fixing seat 1.4, and a cleaning brush fixing seat 1.5. The fixed frame 1.1 is an insulating hollow material, and compressed air circulates in the empty hollow cavity.

[0031] The left and right movable mechanical arms are articulated movable mechanical arms, and the left movable mechanical arm 2 and the right movable mechanical arm 3 respectively comprise a left movable arm bar 2.1 and a right movable arm bar 3.1, a left rotating connecting shaft 2.2, a right rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com