Method for drying a fibrous web in a drying device, and drying device

A technology for drying equipment and fiber materials, which is applied in the field of drying fiber webs and drying equipment in drying equipment, can solve the problem of high cost of fiber webs, and achieve the effect of small expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

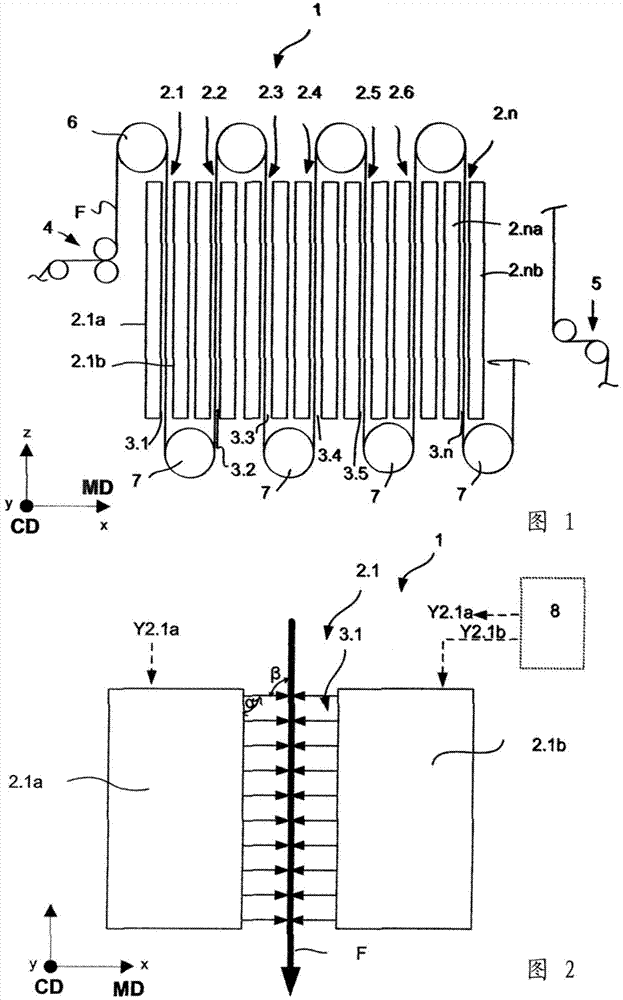

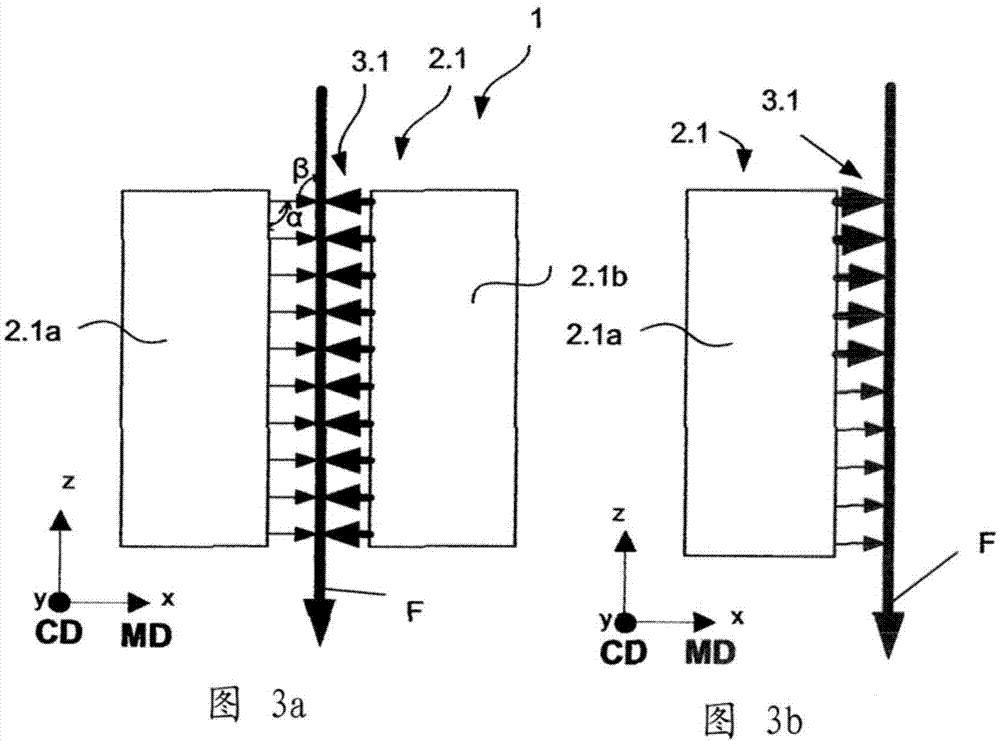

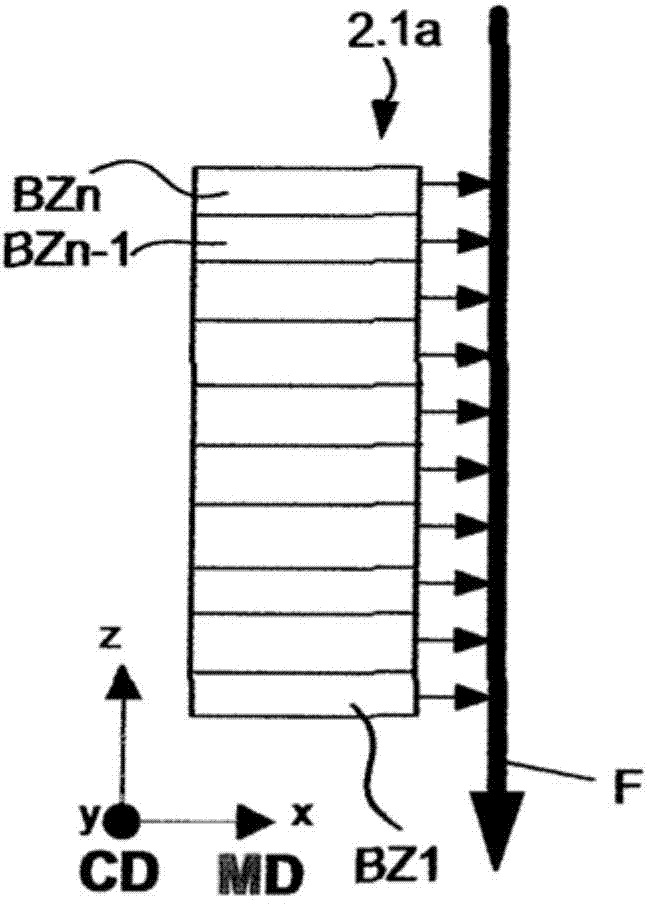

[0069] figure 1 The basic structure and basic functions of the drying plant 1 designed according to the invention are shown very schematically. In order to illustrate the individual direction indications, a coordinate system is established thereon. The X direction corresponds to the basic direction of travel of the fibrous web F through the drying device 1 . It coincides with the longitudinal direction of the drying device 1 and is therefore also referred to as machine direction MD. The Y direction describes the direction perpendicular to the machine direction MD, ie the width direction of the device 1 and is called the machine cross direction CD. The Z direction corresponds to the height direction, ie the extension along the vertical direction.

[0070]According to the invention, the drying device 1 is a vertical drying device according to the impact principle. The fibrous web F is guided through the drying device by multiple deflections, that is to say alternating multip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com