An electric locomotive gis high voltage box

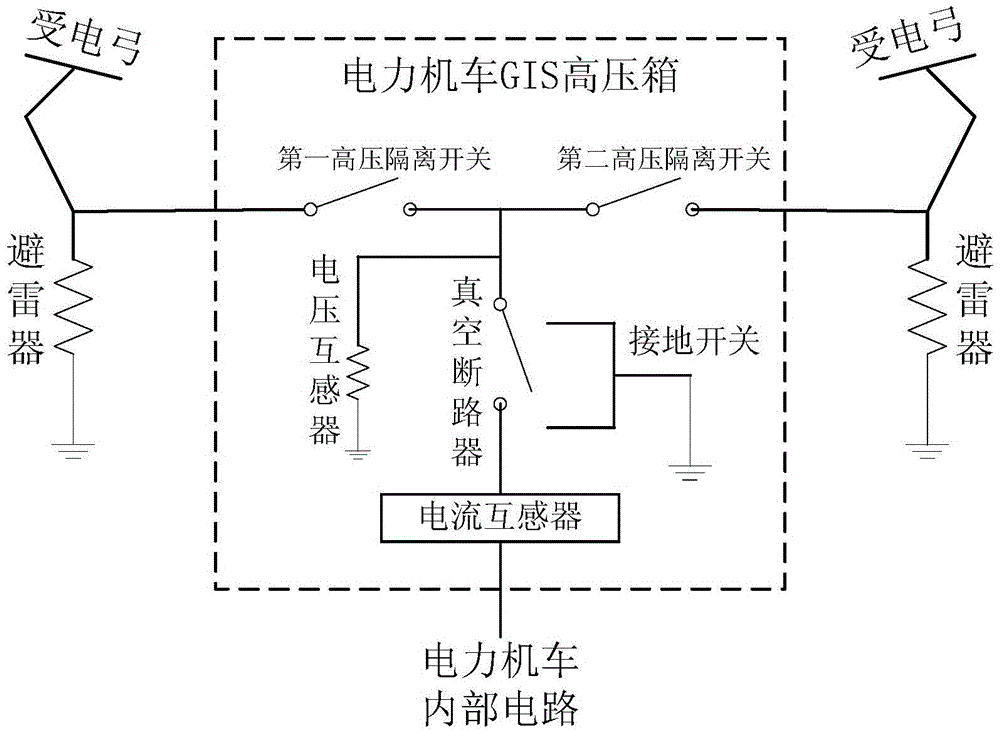

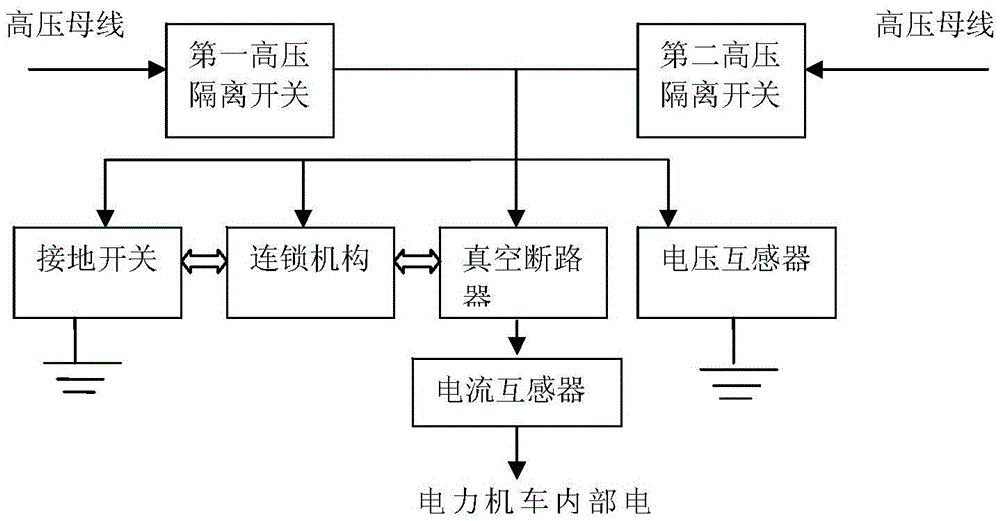

A technology for electric locomotives and high-voltage boxes, which is applied in the direction of electrical components, switchgear, and switchgear settings. It can solve the problems of inconvenient installation and disassembly of high-voltage devices, small space on the top of electric locomotives, and long predetermined electrical safety distances. Efficiency of installation and removal, space reduction, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

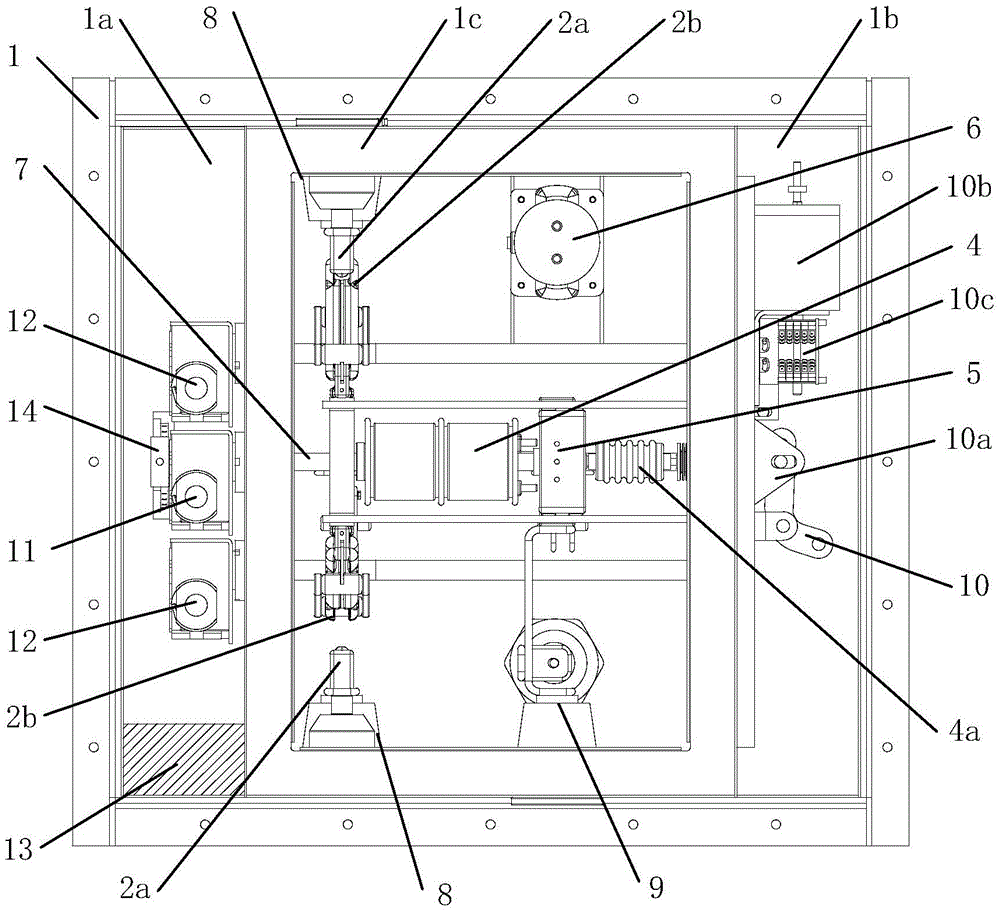

[0024] (1) High-voltage isolating switch: there are two high-voltage isolating switches, which are respectively arranged on the upper and lower parts of the intermediate sealed box 1c; each high-voltage isolating switch includes a isolating switch static contact 2a and an isolating switch moving contact 2b The isolating switch moving contacts 2b of the two high-voltage isolating switches are all installed in the middle of the intermediate sealed box 1c; the isolating switch static contacts 2a of one high-voltage isolating switch are fixed on the top of the intermediate sealed box 1c, and the isolation switch of the other high-voltage isolating switch The switch static contact 2a is fixed on the bottom of the middle sealing box 1c;

[0025] There are two cable inlet terminals 8, which are respectively arranged on the top and bottom of the intermediate sealing box 1c; the static contact 2a of a disconnector switch of a high-voltage isolating switch is electrically connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com