Control of heavy machines

A machine and control board technology, applied in the direction of motor generator control, AC motor control, motor speed or torque control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

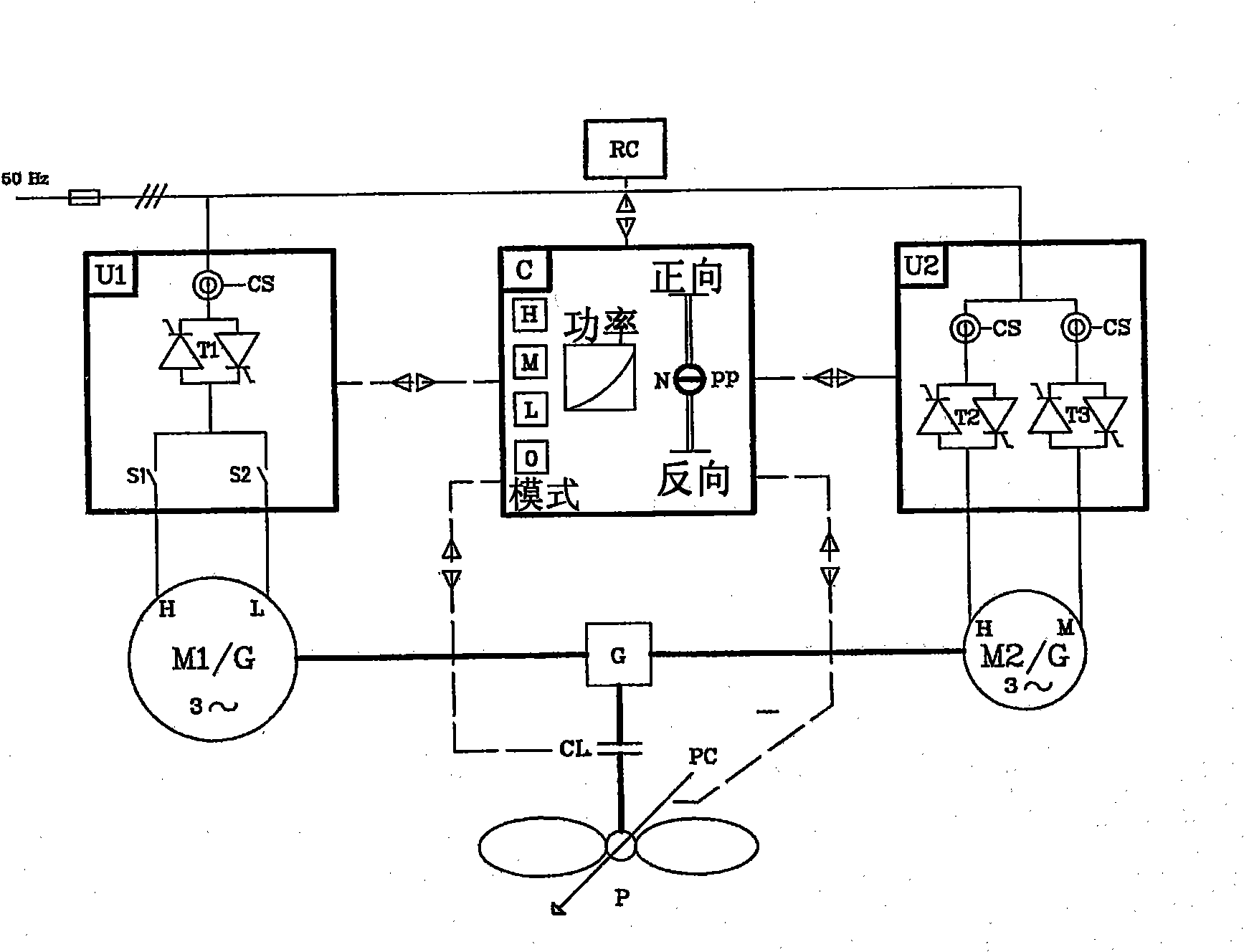

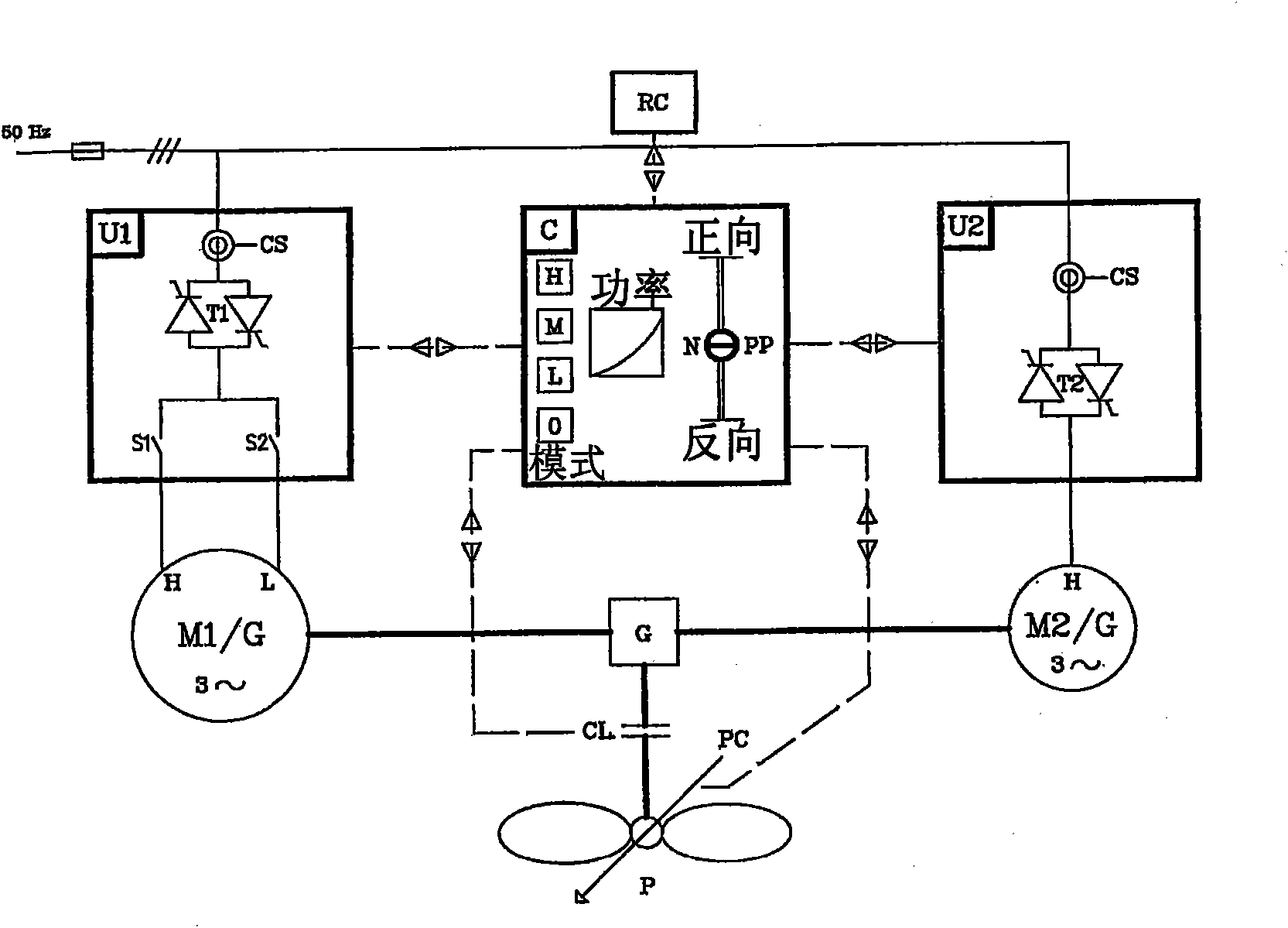

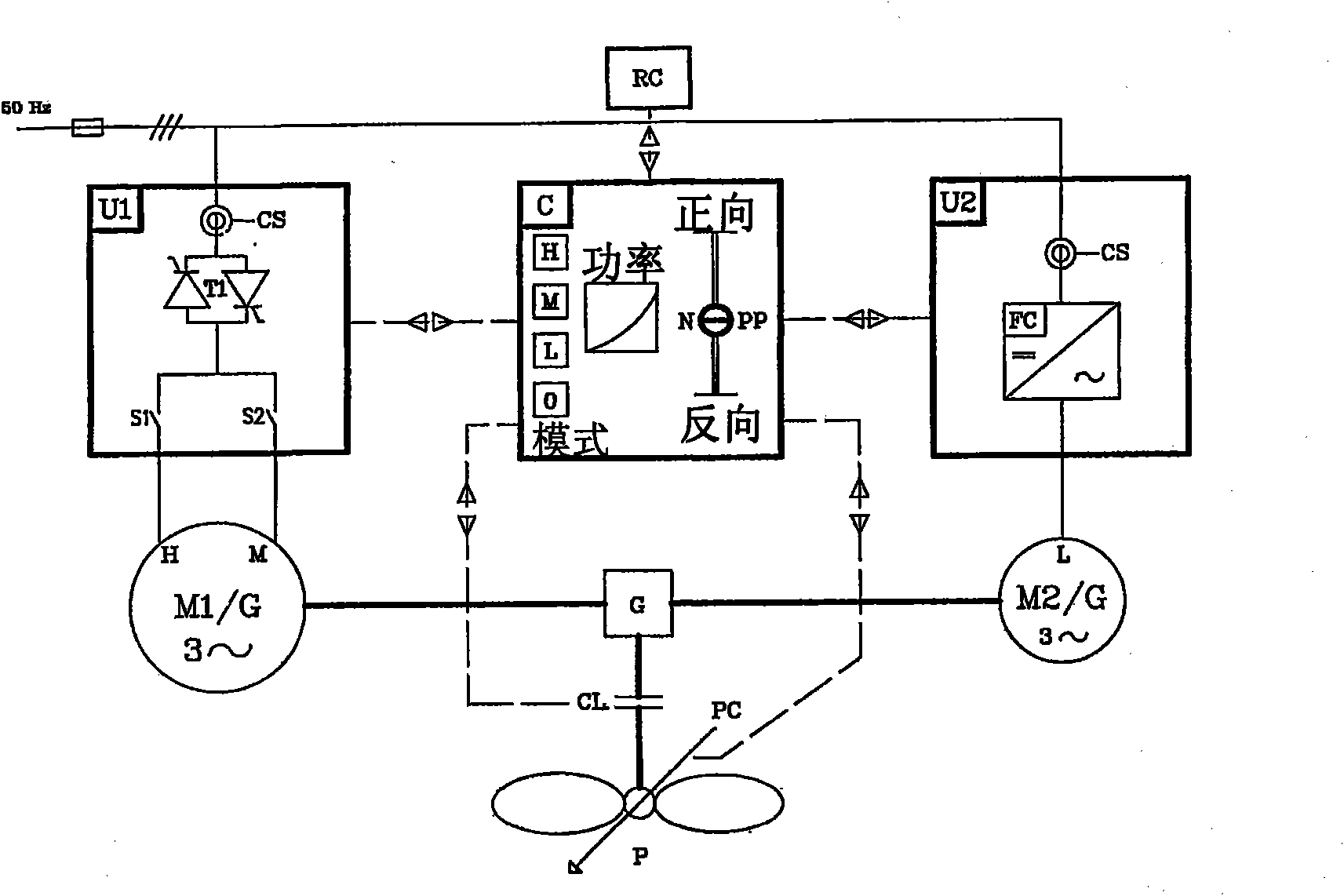

[0040] figure 1 A schematic diagram showing a preferred embodiment of the system according to the invention. Such as figure 1As shown, the system is a three-phase AC system powered by an external power source. The frequency of the external power supply is typically 50 Hz, but other frequencies such as 60 Hz may also be used. A pure sinusoidal waveform current is drawn directly from the grid and delivered to the system, and since the system does not generate significant electrical disturbances, there is no need for example rectification or filtering. Several electric machines can operate as motors and generators, depending only on the direction of the force acting on the mechanical shaft. this is Figure 1 to Figure 8 The M1 / G marked in indicates the cause of the motor or generator.

[0041] The system comprises a three-phase (3~) two-speed electric motor M1, M2, preferably an asynchronous motor, mechanically connected to a gear G and which will drive a processing machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com