Plasma processing equipment

A plasma and processing equipment technology, applied in the field of plasma processing equipment, can solve the problems that affect the efficiency of plasma processing equipment, the mechanical parts are easily damaged, and the structure is complicated, and achieve the effects of good fixation, reduced maintenance costs, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

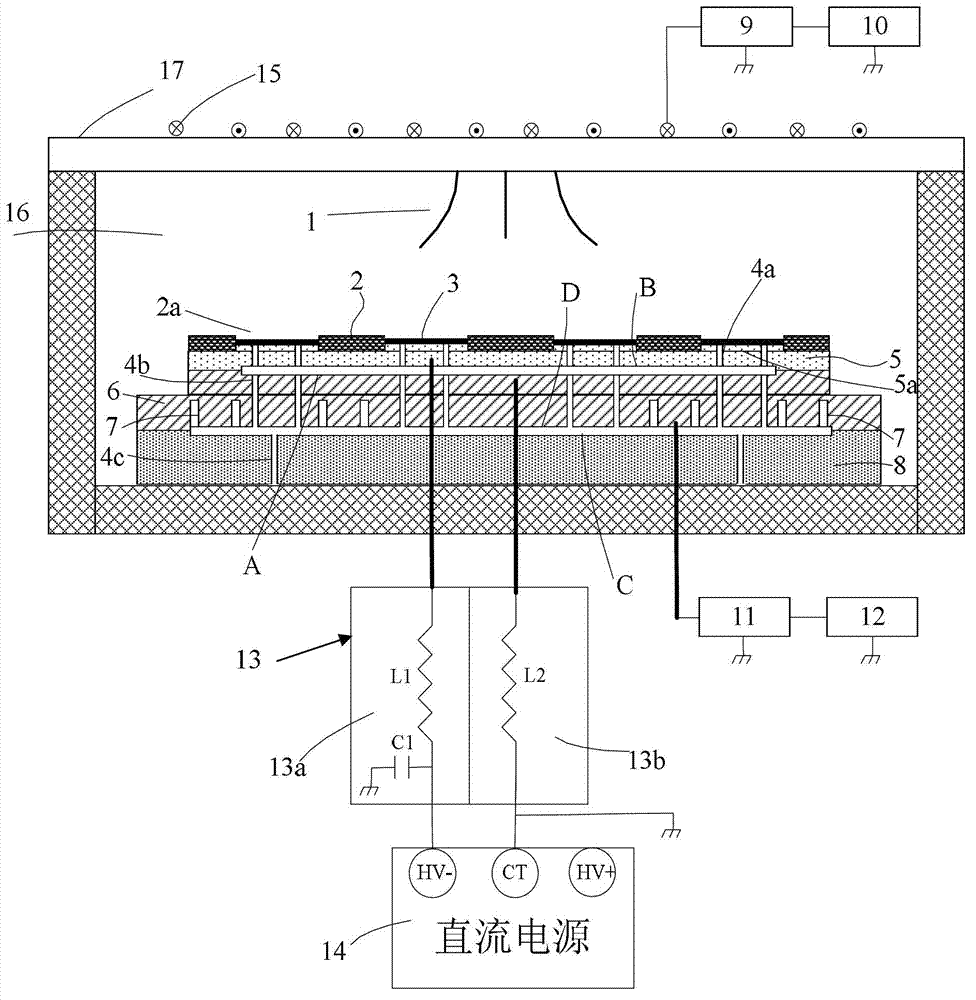

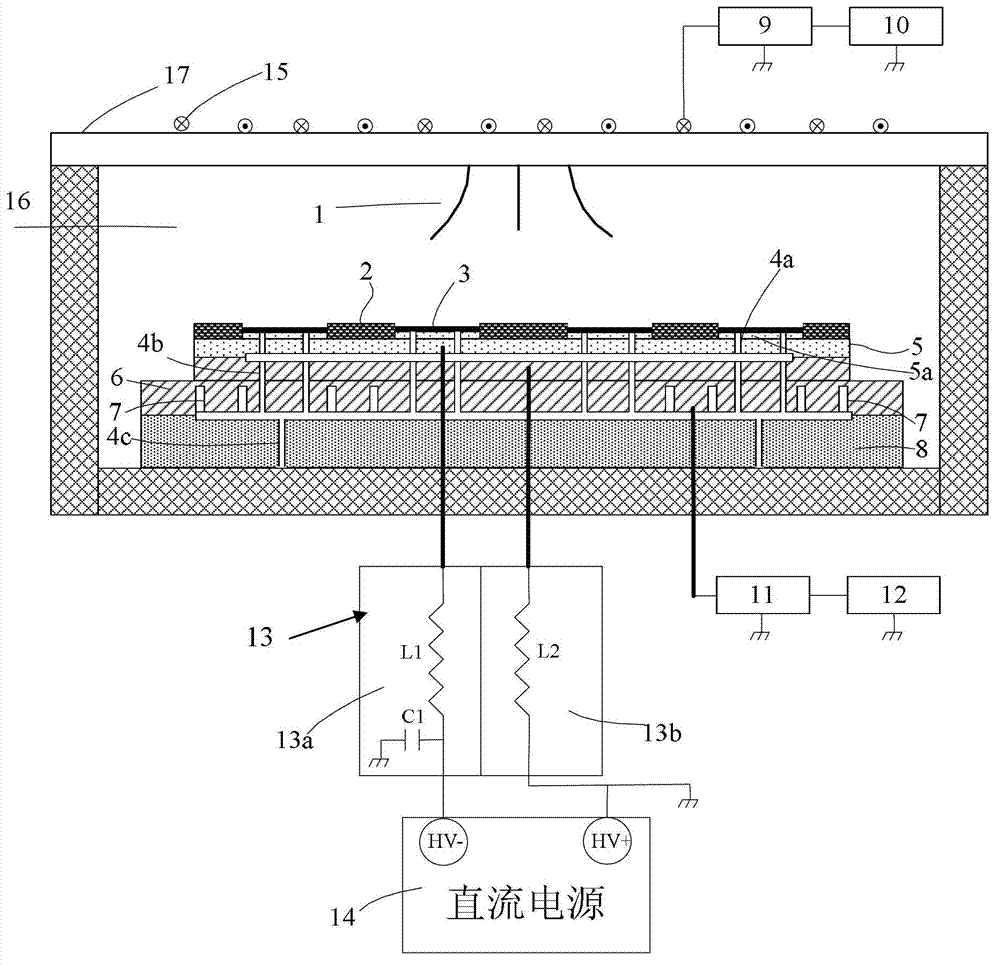

[0053] In order to enable those skilled in the art to better understand the technical solution of the present invention, the plasma processing device provided by the present invention will be described in detail below with reference to the accompanying drawings.

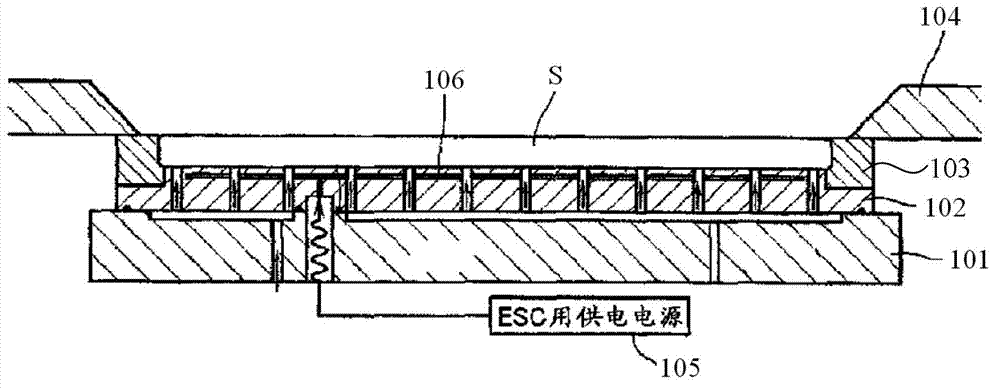

[0054] An embodiment of the present invention provides a plasma processing device, figure 2 It is a schematic cross-sectional view of a partial structure of a plasma processing device according to an embodiment of the present invention. Such as figure 2 As shown, the plasma processing apparatus includes a reaction chamber 16, the walls of which are grounded. The bottom of the reaction chamber 16 is provided with a chuck base 8, the chuck 6 is fixed on the top of the chuck base 8, and the tray 5 is placed on the bearing surface of the chuck 6 (the upper surface of the chuck shown in the figure). 5 is used to carry the wafer 3. A dielectric window 17 is provided on the top of the reaction chamber 16 , and the indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com