Method for determining position of root of blast furnace cohesive zone through multi-source information fusion

A technology of multi-source information fusion and reflow zone, which is applied in the field of iron and steel smelting, can solve the problems of backward detection technology of reflow zone position and shape, difficulty in giving accurate results, etc., and achieve low equipment investment and strong operability , the effect of high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The blast furnace used is a 2500m steel plant 3 level blast furnace.

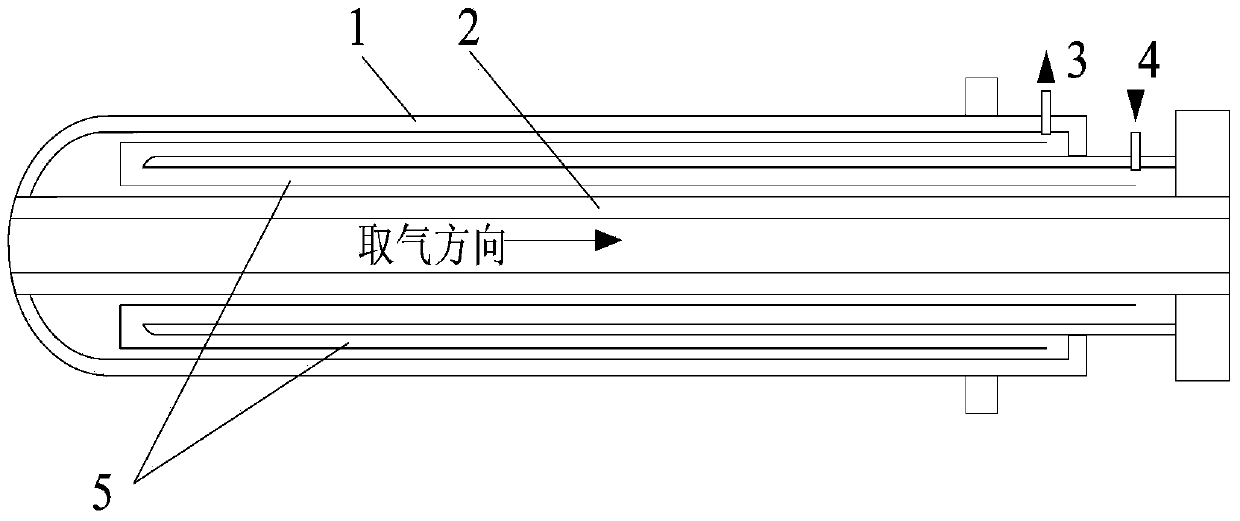

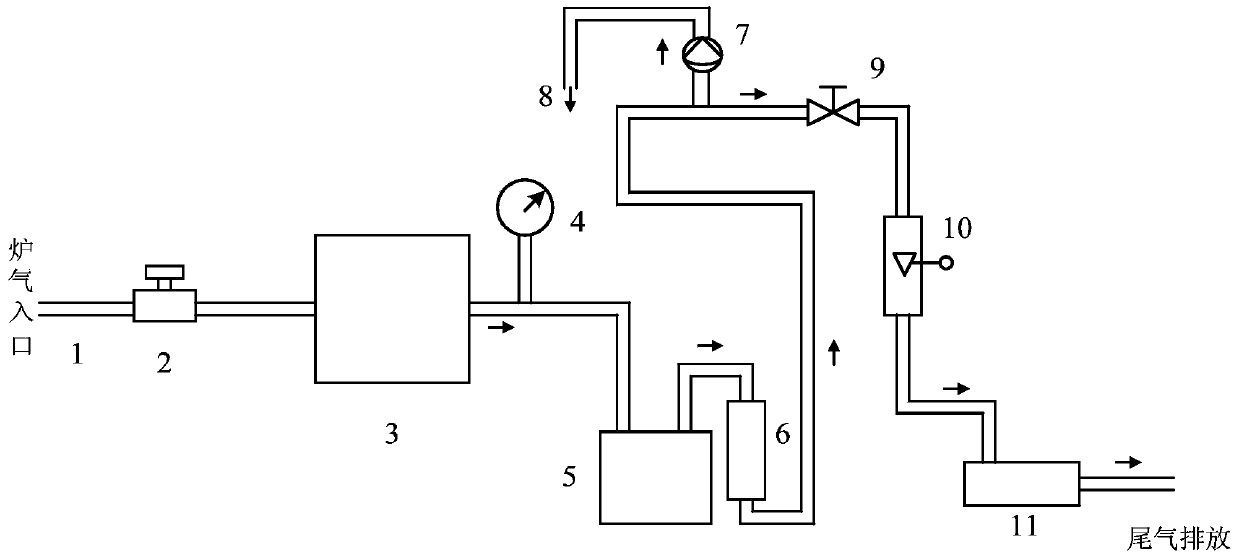

[0056] A Take blast furnace gas along different heights of the blast furnace shaft, measure and draw the distribution curve of gas utilization along the height direction, and use numerical calculation methods to obtain η co The elevation position of zero (the flow chart of blast furnace gas composition extraction and analysis is shown in figure 2 , the blast furnace gas is taken out from the sampling probe 1, and flows through the high-pressure anti-corrosion solenoid valve 2, dust filter 3, alarm pressure gauge 4, gas-water separator 5, dryer 6, explosion-proof air pump 7, residual gas recovery 8, regulation valve 9, gas flow meter 10, gas chromatograph analyzer 11 for extraction and analysis);

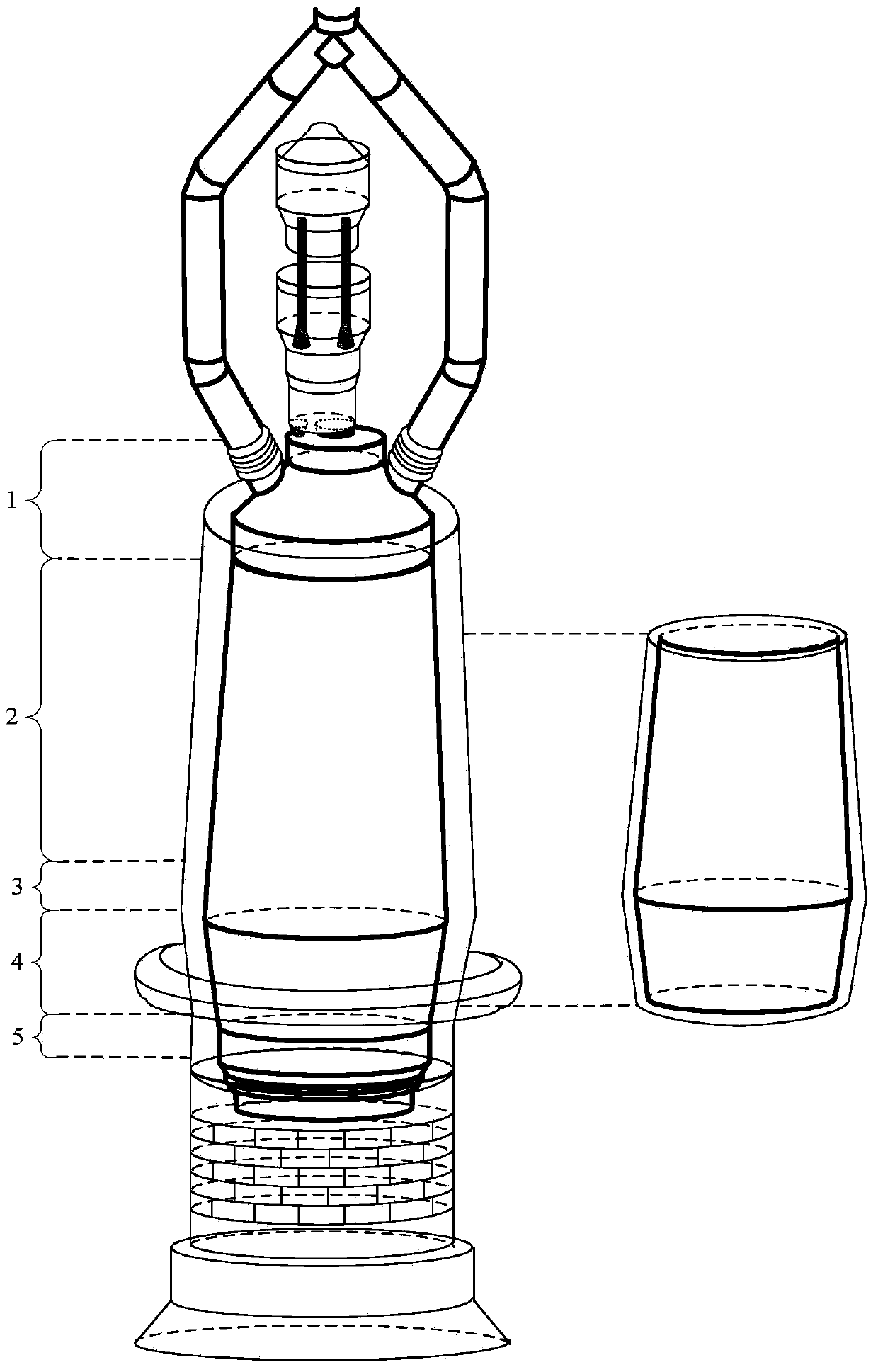

[0057] A1 The blast furnace is equipped with static pressure holes (total 12 points) in the four directions of east, south, west and north on the three floors with the height of the furnace body (relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com