Diffusion plate, manufacturing method thereof and backlight module

A technology of backlight module and manufacturing method, which is applied in the direction of optics, light source, electric light source, etc., to achieve the effect of increasing the degree of scattering, reducing the H/P value, and suppressing the problem of color cast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

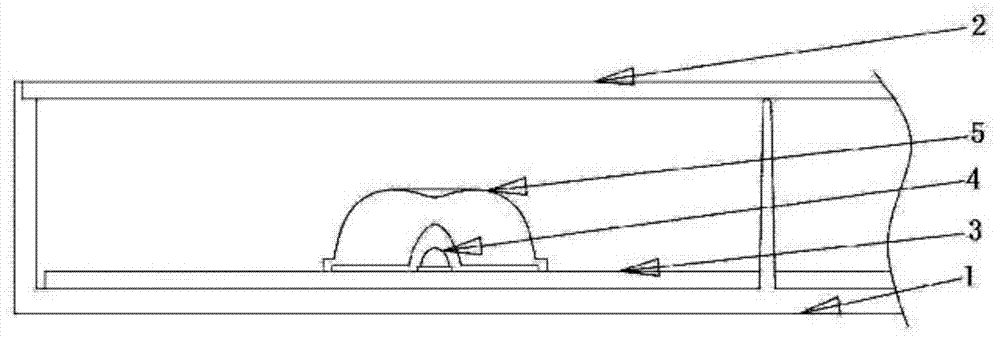

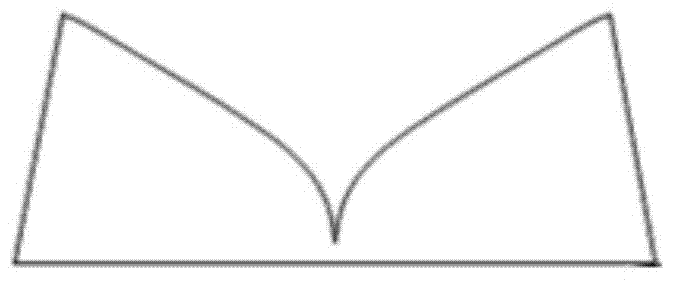

[0034] As mentioned in the background technology, although the reflective secondary lens can reduce the H / P value in the backlight module, but because the existing LED white light source is made by mixing blue light and yellow light, after entering the reflective secondary lens , part of the yellow light is directly refracted from the top of the lens because it does not meet the total reflection condition, so that the light spot formed by the reflective secondary lens has a color cast phenomenon.

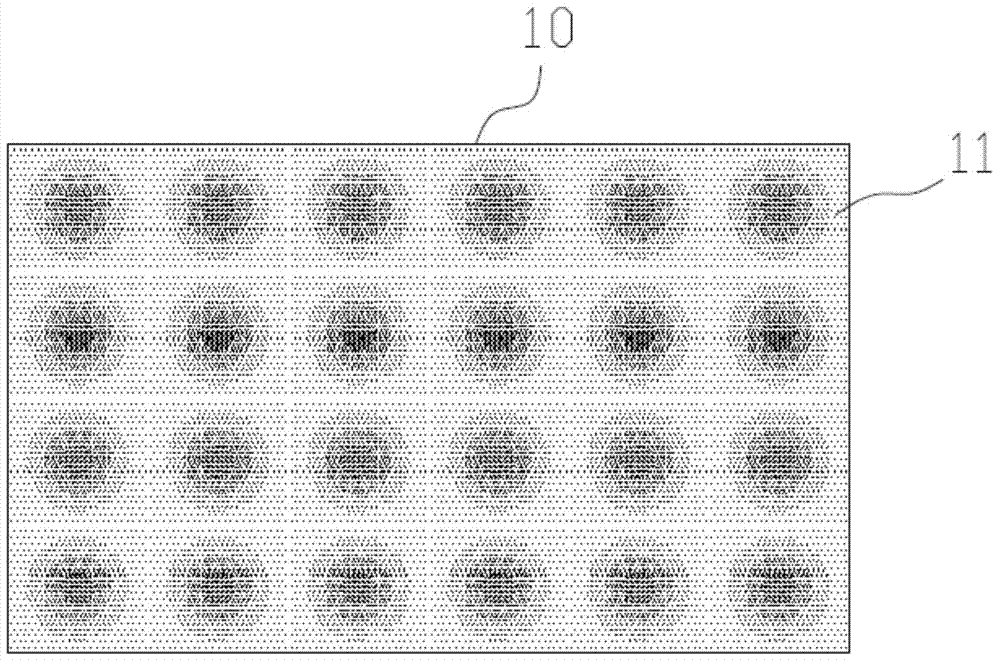

[0035] In order to improve the above problems, the present invention designs a diffuser plate, which is provided with reflective dots that cooperate with yellow light to form white light, and these reflective dots are formed by adding a small amount of blue ink to white ink. According to the complementary color principle of light, after the yellow light is incident on these reflective dots, it can cooperate to form white light, reduce the yellow light component in the mixed color lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com