Display substrate and manufacturing method thereof, display panel and display device

A technology for a display substrate and a manufacturing method, which is applied in the fields of display panels and display devices, display substrates and manufacturing methods thereof, and can solve the problems of poor display effects and reduced light extraction efficiency of display devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical problems, technical solutions, and advantages to be solved by the embodiments of the present invention clearer, a detailed description will be given below with reference to the drawings and specific embodiments.

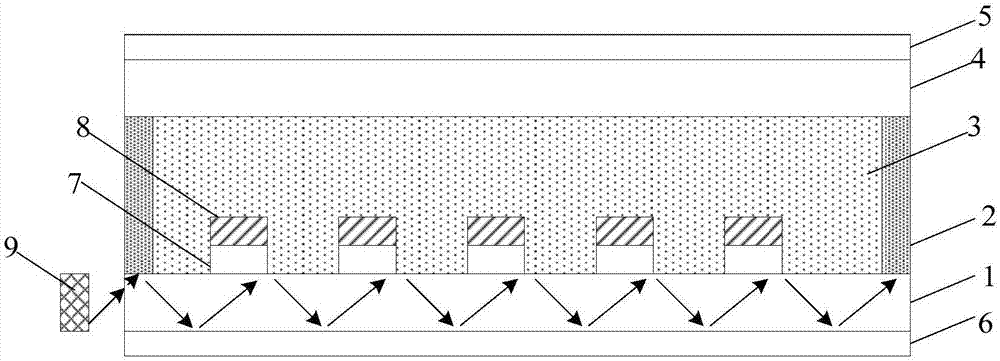

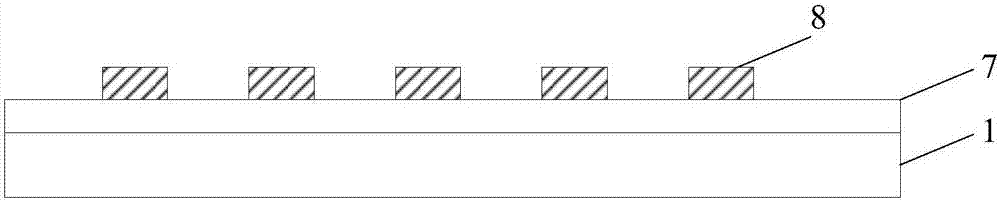

[0043] Such as figure 1 As shown, the existing display device includes a base substrate 1, 4 arranged in a pair of cells up and down, and a liquid crystal layer 3 located between the base substrates 1, 4, and a side of the base substrate 1 close to the liquid crystal layer 3 may be provided The waveguide layer, the refractive index of the waveguide layer is greater than the refractive index of the base substrate 1, or as figure 1 As shown, the base substrate 1 is directly used as the waveguide layer. The base substrate 1 is provided with a plurality of light-transmitting insulating patterns 7 arranged at intervals on the side close to the liquid crystal layer 3, and electrodes 8 are arranged on the light-transmitting insulating patter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com