Power cable insulation monitoring system

A technology for insulation monitoring and power cables, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems such as the inability to realize random cable detection, hidden dangers to the personal safety of operators, and influence on production and life, and achieve the goal of overcoming close-range operation detection equipment, ensuring accuracy and reliability, and improving the effect of power supply service quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

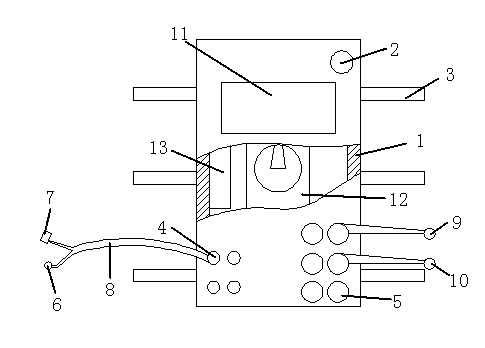

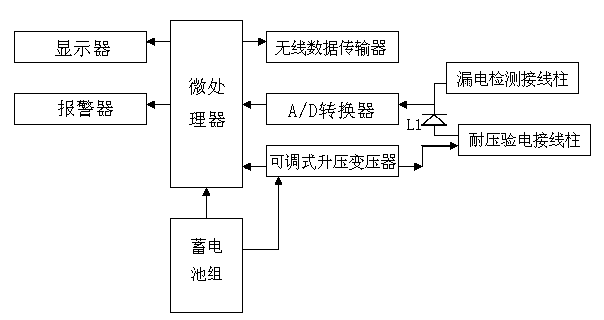

[0015] Such as figure 1 and 2 As shown, a power cable insulation monitoring system, the power cable insulation monitoring system is composed of a housing 1, a leakage electric contact, a withstand voltage electric contact, a controller and an alarm 2, and the outer surface of the housing 1 is An elastic connection belt 3 is provided, and at least two leakage detection terminal posts 4 and at least two withstand voltage test terminal posts 5 are provided on the upper surface of the housing 1, and at least one alarm device 2 is provided in addition, and the leakage test contact is provided by An electrostatic sensor 6 and a Hall closed-loop leakage current sensor 7 are connected in parallel, and are connected to the leakage detection terminal 4 through a wire 8. The pressure-resistant electric contact is composed of an internal contact 9 and an external contact 10. The internal contact 9 and the external contact 10 are both cylindrical, and are respectively connected to the wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com