Eddy current non-contact multi-channel diameter detector in pipeline

An eddy current, multi-channel technology, applied in the direction of electric/magnetic diameter measurement, electromagnetic measuring device, electric/magnetic solid deformation measurement, etc., can solve the problems of low precision, poor anti-interference ability, complex structure, etc., and achieve compact structure, The effect of high precision and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

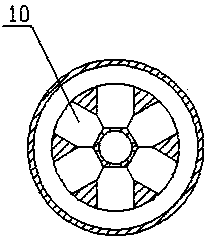

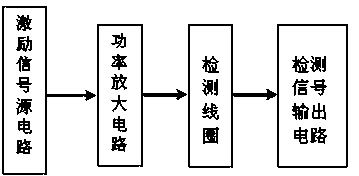

[0022] according to Figure 1 to Figure 2 The present invention is described in detail. The present invention includes a pre-conditioner compartment 2, a computer compartment 4 and a battery compartment 8 which are all tubular. The pre-conditioner compartment 2, the computer compartment 4 and the battery compartment 8 are arranged in sequence, and the adjacent compartment bodies are connected by a coupling 7. , supporting wheels 5 are evenly distributed along the circumferential direction on the outer sides of the pre-driver compartment 2, the computer compartment 4 and the battery compartment 8; a power cup 1 is arranged at the axial front end of the pre-driver compartment 2, and an eddy current detection ring is arranged at the rear end. 3. The eddy current detection ring is provided with six channels of eddy current sensor 10; a single-chip data processing unit is provided in the computer compartment, and a data memory and a USB socket are attached; the eddy current detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com