Regulating valve

A regulating valve and valve needle technology, applied in the field of regulating valves, can solve problems such as large cutting parameters, difficult machining procedures, small machining tools, etc., to meet the needs of small flow adjustment, reduce production costs, and improve manufacturing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

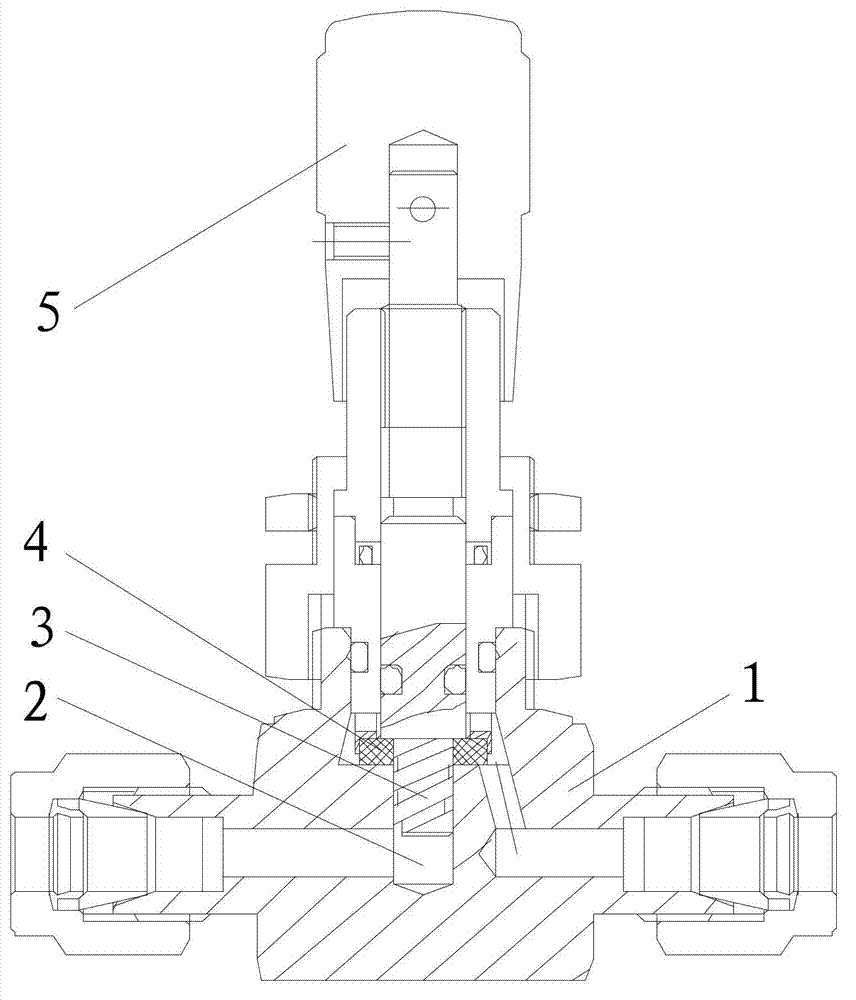

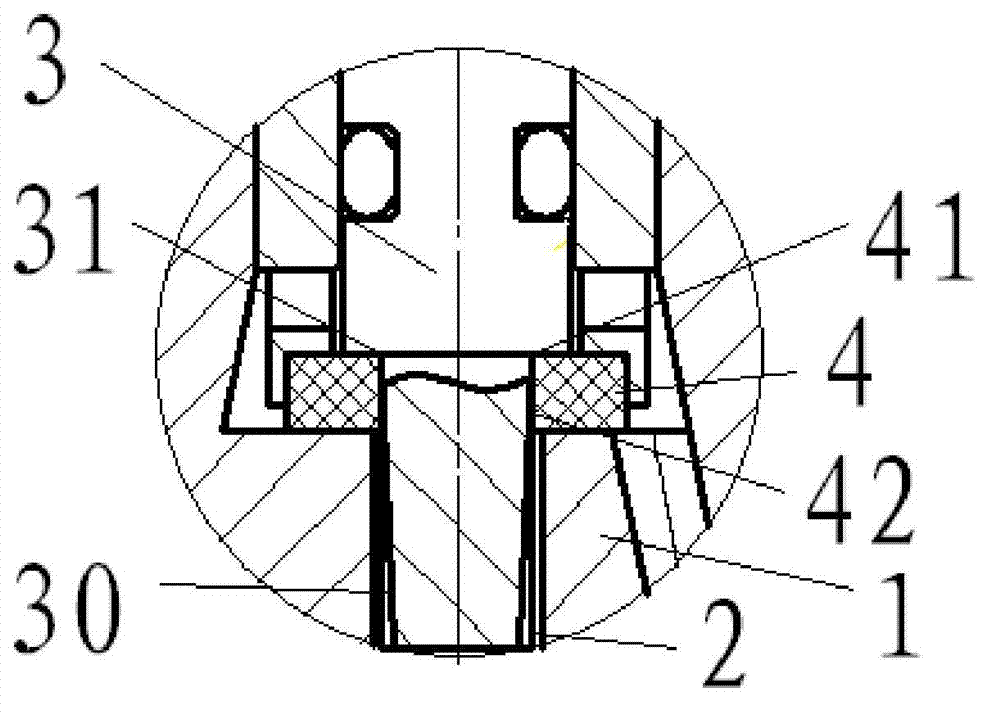

[0055] see figure 1 and figure 2 , a regulating valve, comprising a valve seat 4, a valve seat hole 42 is arranged in the valve seat 4, a valve needle 3 is arranged in the valve seat hole 42, a groove 30 is arranged on the side wall of the valve needle 3, and the groove 30 can Change the size of the flow surface.

[0056] By processing the groove on the side wall of the valve needle, the adjustment of the small flow can be realized, and the invention is easy to process and has low production cost.

[0057] In the present invention, a detailed description is given by taking the cylindrical valve seat hole with the cylindrical valve needle and two axial linear grooves on the side wall as an example:

[0058] On the basis of the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com