Superhigh-temperature flat gate valve

A flat gate valve, ultra-high temperature technology, applied in the direction of sliding valves, valve devices, engine components, etc., can solve the problems of high cost, complex processing, unreliable sealing, etc., achieve small erosion and erosion, good manufacturing process, and valve opening powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

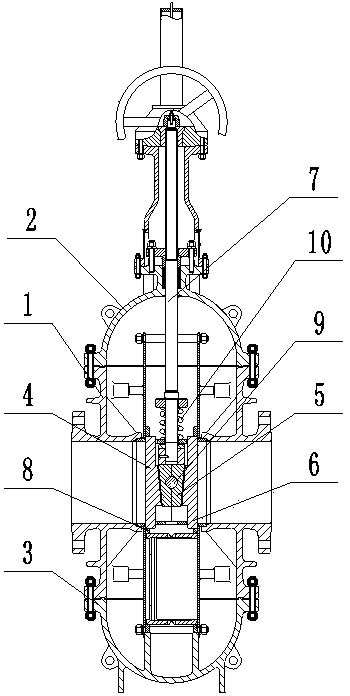

[0013] Such as figure 1 As shown, the ultra-high temperature slab gate valve of the present invention includes a valve body 1, an upper bonnet 2, a lower bonnet 3 and a valve stem 7, the valve body 1 is arranged between the upper bonnet 2 and the lower bonnet 3, and the valve body 1 It is fixedly connected with the upper bonnet 2 and the lower bonnet 3, and the inside of the valve body 1 is provided with a gate assembly 4 and a gate fixing frame 8, and the gate assembly 4 includes an inner gate 5 and an outer gate 6 , the inner flashboard 5 is movably arranged inside the outer flashboard 6, and the outer flashboard 6 is fixedly arranged on the flashboard fixing frame 8, and the inside of the inner flashboard 5 is provided with a steel ball 9, and the valve stem 7 can be rotated 90° by driving and installed in the valve body 1, the steel ball 9 is fixedly connected with the valve stem 7, so that the valve stem 7 drives the steel ball 9 to rotate in the valve body 1, thereby rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com