A method for efficient utilization of high manganese pig iron

A high manganese, pig iron technology, applied in the field of pig iron, can solve problems such as many shortcomings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

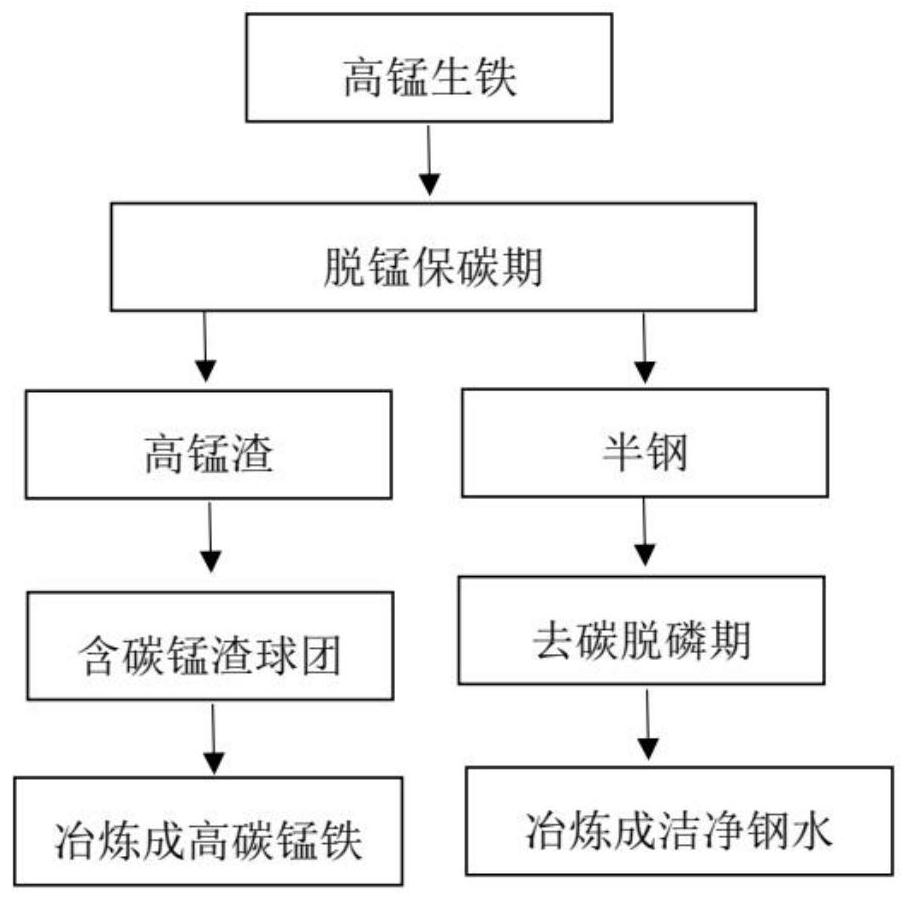

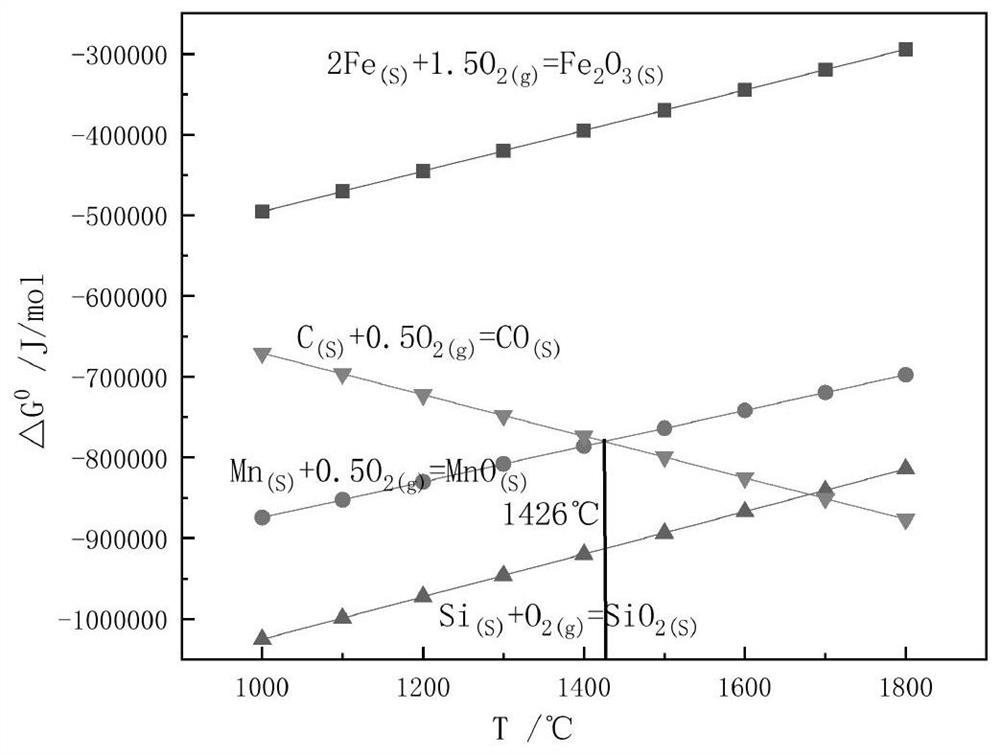

[0068] In the method for high-efficiency utilization of high manganese pig iron provided in this embodiment, the purpose of smelting high manganese pig iron is to achieve the purpose of smelting high manganese pig iron by supplying oxygen through an oxygen lance in a 500t induction furnace and blowing nitrogen into the bottom blowing to stir the molten pool.

[0069] In the demanganization and carbon preservation period, 200kg of high manganese pig iron, its chemical composition is C 3.6%, Si≤0.01%, Mn 8.34%, P0.14%, S 0.02%, the rest is Fe and trace unavoidable impurities; The power is 120kw; the oxygen supply intensity is 0.6Nm 3 / (t·min), the end point temperature is controlled at 1350°C, iron ore is added to cool down during the blowing process, 13kg / t iron ore is added every 2min, and the amount of iron ore added is 130kg / t. The oxygen supply time is 34min, and the oxygen supply volume is 4.08m 3 , the bottom blowing gas supply intensity is 0.12Nm 3 / (t min); After blow...

Embodiment 2

[0072] In the method for high-efficiency utilization of high-manganese pig iron provided in this embodiment, oxygen is supplied through an oxygen lance in a 500 t induction furnace, and nitrogen is blown into the bottom blowing to stir the molten pool, so as to obtain the purpose of smelting high-manganese pig iron.

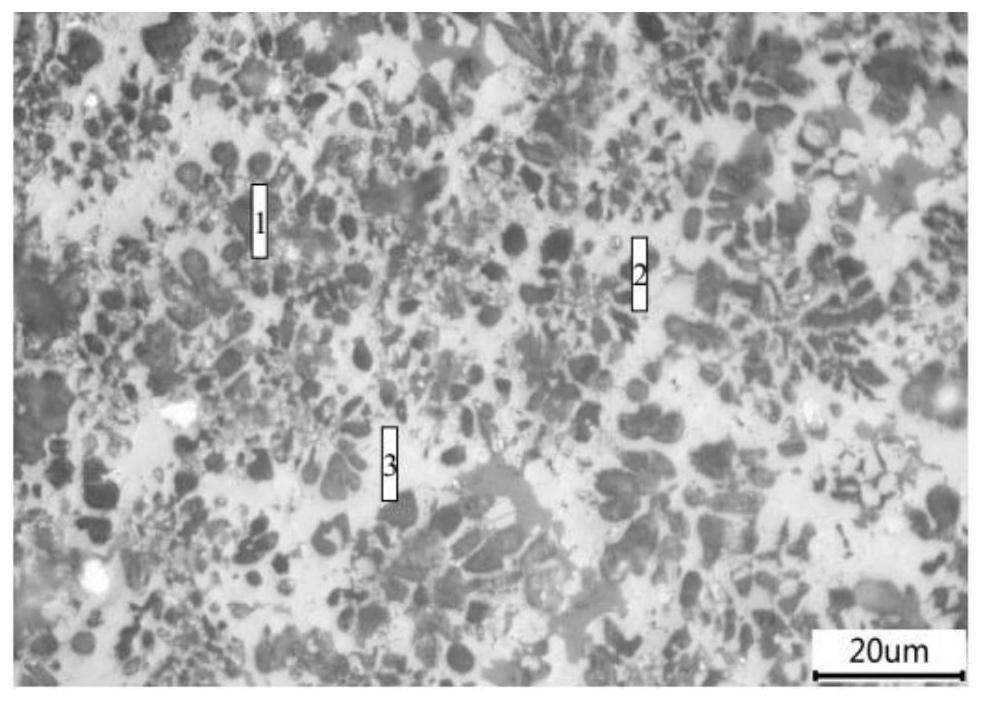

[0073] In the demanganization and carbon preservation period, 250kg of high manganese pig iron, its chemical composition is C 4.0%, Si 0.008%, Mn 9.42%, P0.13%, S 0.02%, the rest is Fe and trace unavoidable impurities; the heating power 120kw; oxygen supply intensity is 1.0Nm 3 / (t min), the end point temperature is controlled at 1300°C, iron ore is added to cool down during the blowing process, and the amount of iron ore added is 138kg / t; the oxygen supply time is 25min, and the oxygen supply amount is 6.25m 3 , the bottom blowing gas supply intensity is 0.12Nm 3 / (t·min). After blowing, pour out high manganese slag, its chemical composition is Fe 2 o 3 15.2...

Embodiment 3

[0076] In the method for high-efficiency utilization of high manganese pig iron provided in this embodiment, the purpose of smelting high manganese ferromanganese is obtained by supplying oxygen through an oxygen lance in a 500t induction furnace, and blowing nitrogen into the bottom blowing to stir the molten pool.

[0077] In the demanganization and carbon preservation period, 150kg of high manganese pig iron, its chemical composition is C 4.2%, Si 0.009%, Mn 10.12%, P 0.11%, S 0.021%, the rest is Fe and trace unavoidable impurities; the oxygen supply intensity is 1.2Nm 3 / (t·min), the end point temperature is controlled at 1400°C, iron ore is added to cool down during the blowing process, and the amount of iron ore added is 140kg / t. The oxygen supply time is 25min, and the oxygen supply volume is 4.5m 3 , the bottom blowing gas supply intensity is 0.10Nm 3 / (t·min). After blowing, pour out high manganese slag, its chemical composition is Fe 2 o 3 15.6%, MnO 76.4%, SiO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com