A pull-bolt type magnetic lock with spin lock

A magnetic lock and pull-bolt technology, applied in construction locks, non-mechanical transmission-operated locks, buildings, etc., can solve the failure of the brake ring to move, the failure of the pull-bolt-type magnetic lock, and the inability to pull out the pull-bolt, etc. problem to achieve smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

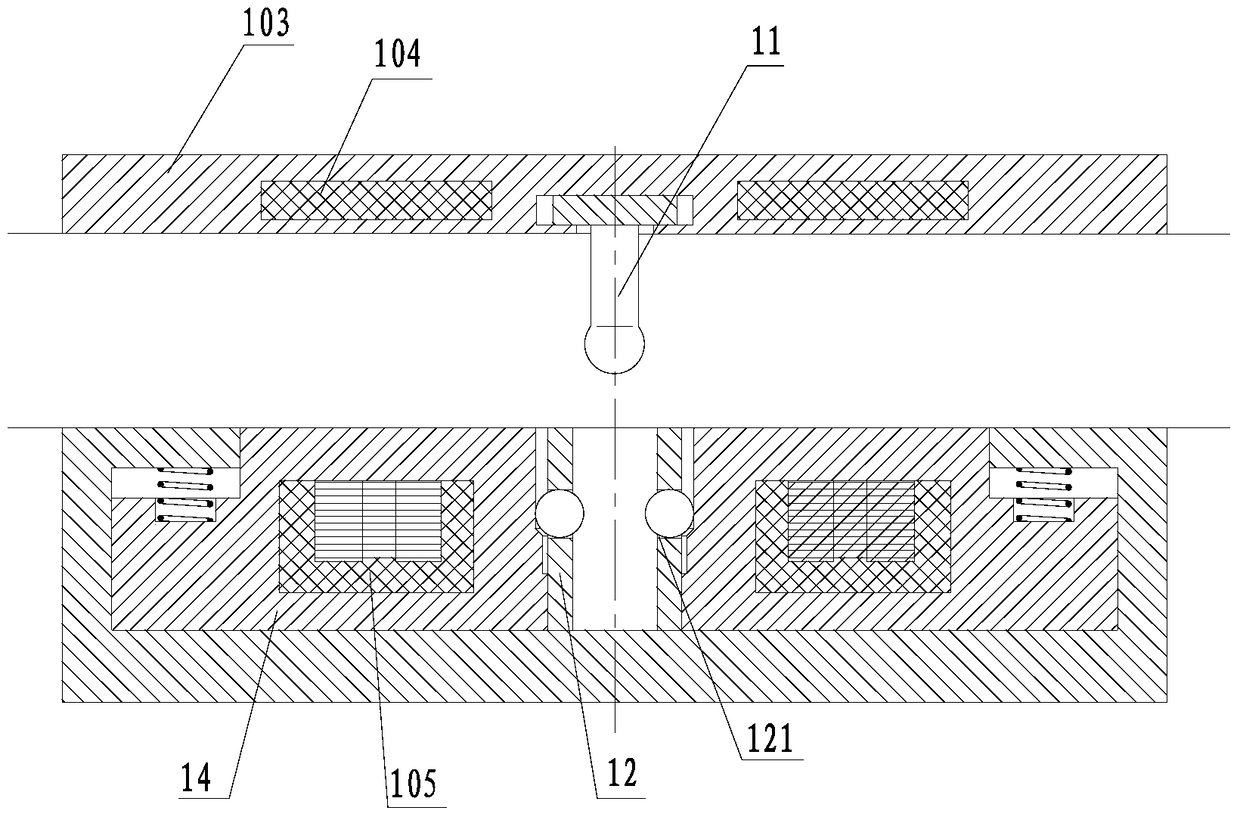

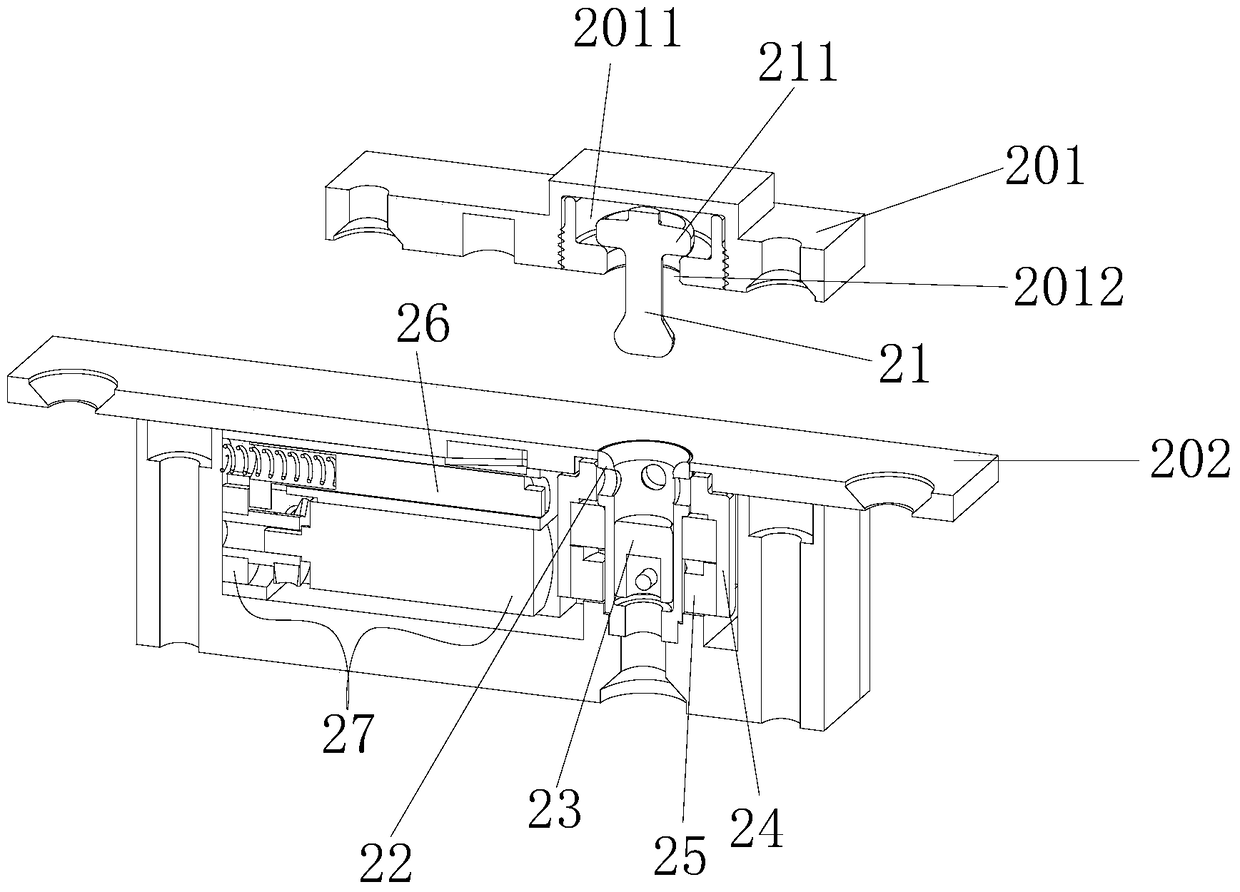

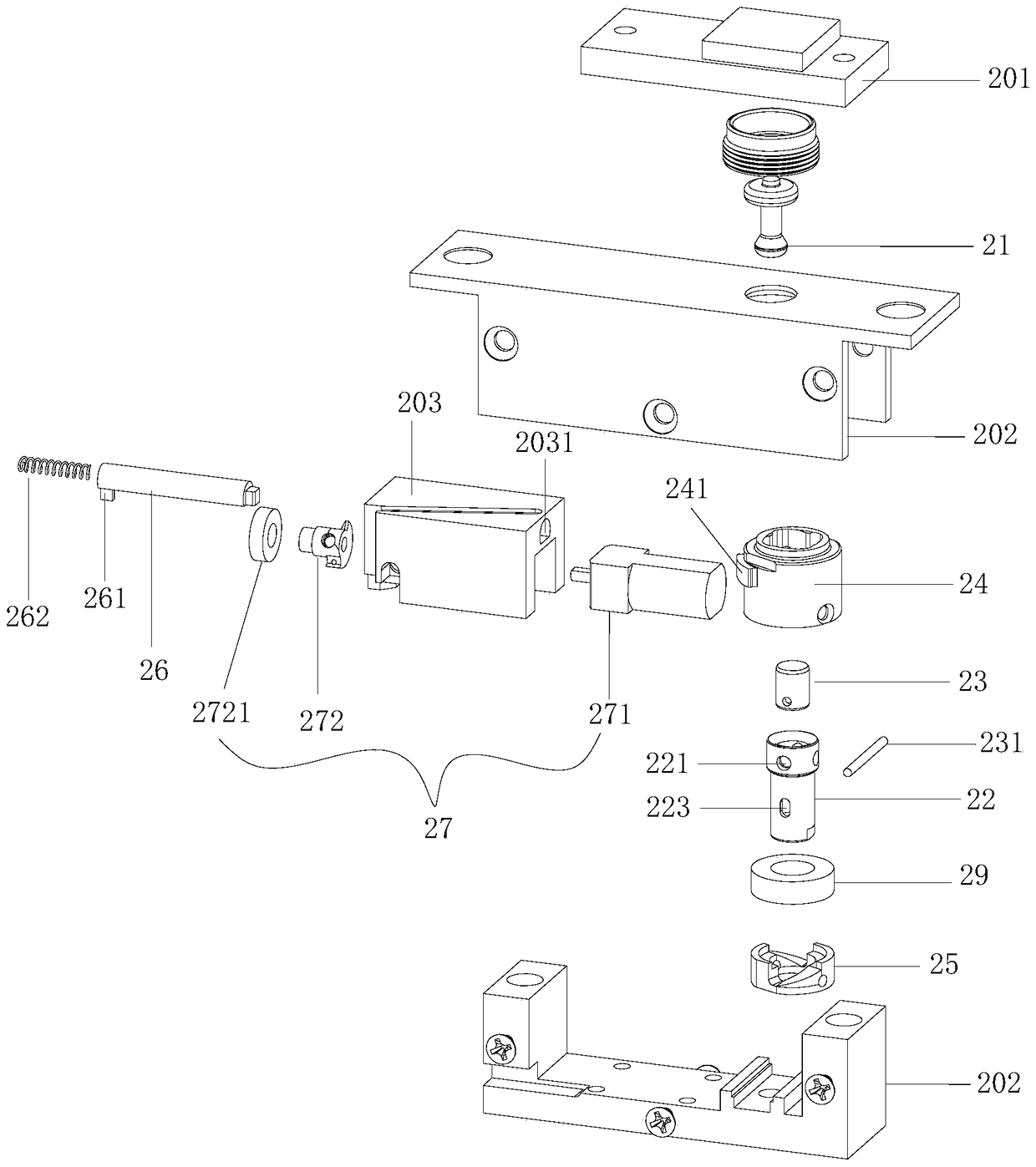

[0028] like figure 2 and image 3 As shown, the spin-locking pull bolt type magnetic lock according to an embodiment of the present invention includes a vertical raised pull bolt 21 with a flange on one side of the door, and an upper opening fixed on the other side of the door. The sleeve 22 which can be inserted into the pull bolt 21, the plug 23 in the sleeve which can move axially relative to the sleeve 22 in the sleeve 22, the brake ring 24 sleeved outside the sleeve 22, the brake ring 24 and A rotating member 25 between the sleeves 22 that can rotate synchronously with the brake ring 24, extends axially perpendicular to the brake ring 24, and one end cooperates with the radial deformation area 241 on the outer wall of the brake ring 24 to stop or release the brake. The pin 26 of the moving ring 24 and the pin drive assembly 27. The sleeve 22 and the brake ring 24 have a mechanism for adjusting the hole diameter of a part of the inner cavity of the sleeve 22 in cooperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com