Adjustable length tie rod assembly

A technology of oblique tie rods and components, which is applied in the field of fixing devices, can solve the problems of product dumping, failure of tie rod support, increase of gas cutting, and grinding processes, etc., so as to achieve the effect of facilitating assembly and avoiding locking failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

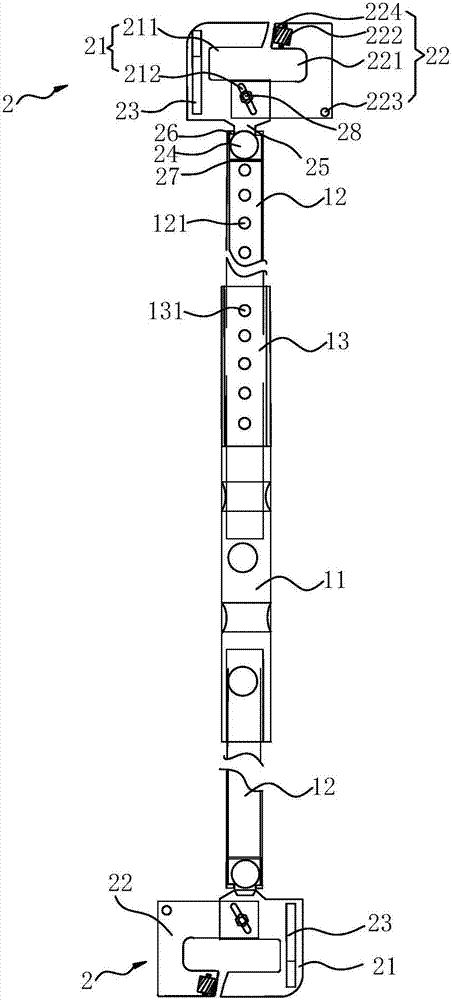

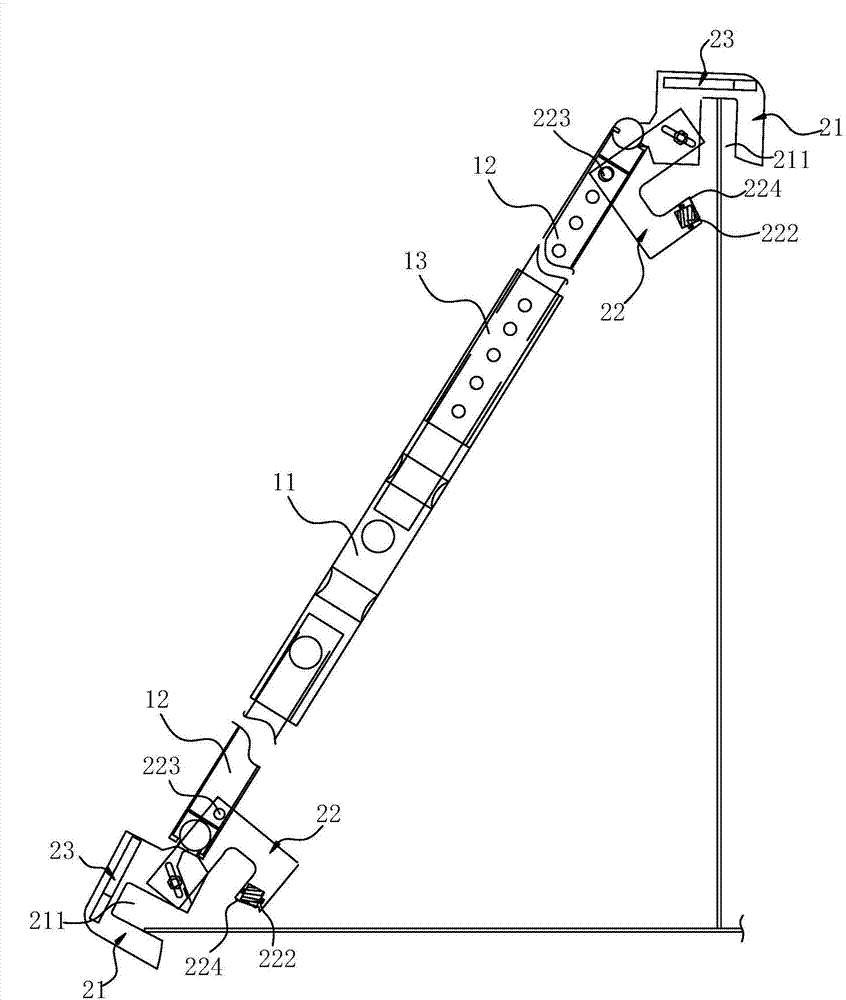

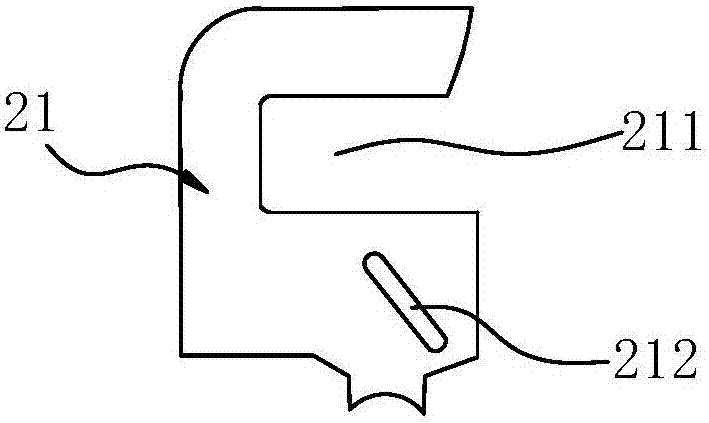

[0046] Such as Figures 1 to 8 As shown, the length-adjustable diagonal tie rod assembly provided by the embodiment of the present invention includes a pull rod mechanism 1 and two jaw mechanisms 2, wherein the pull rod mechanism 1 includes a sleeve rod 11, an elongated steel pipe 13 and a connecting steel pipe 12, and the elongated steel pipe The two ends of 13 are respectively socketed with the sleeve rod 11 and the connecting steel pipe 12, and the sleeve rod 11 and the connecting steel pipe 12 can move relatively along the length direction of the growth steel pipe 13, and the growth steel pipe 13 is A plurality of first fixing holes 131 are arranged at equal intervals along its length direction, and a plurality of second fixing holes 121 are arranged at equal intervals along the length direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com