External-heated and solid heat carrier combined rotary dry-distillation method and device

A solid heat carrier, external heat technology, which is applied in the combination of direct and indirect heating for dry distillation, special form dry distillation, direct heating dry distillation, etc. It can solve the problems of low calorific value of gas, inability to dry distillation of surface coal, etc., and reduce the amount of waste water. , The amount of dust is small, and the effect of increasing thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

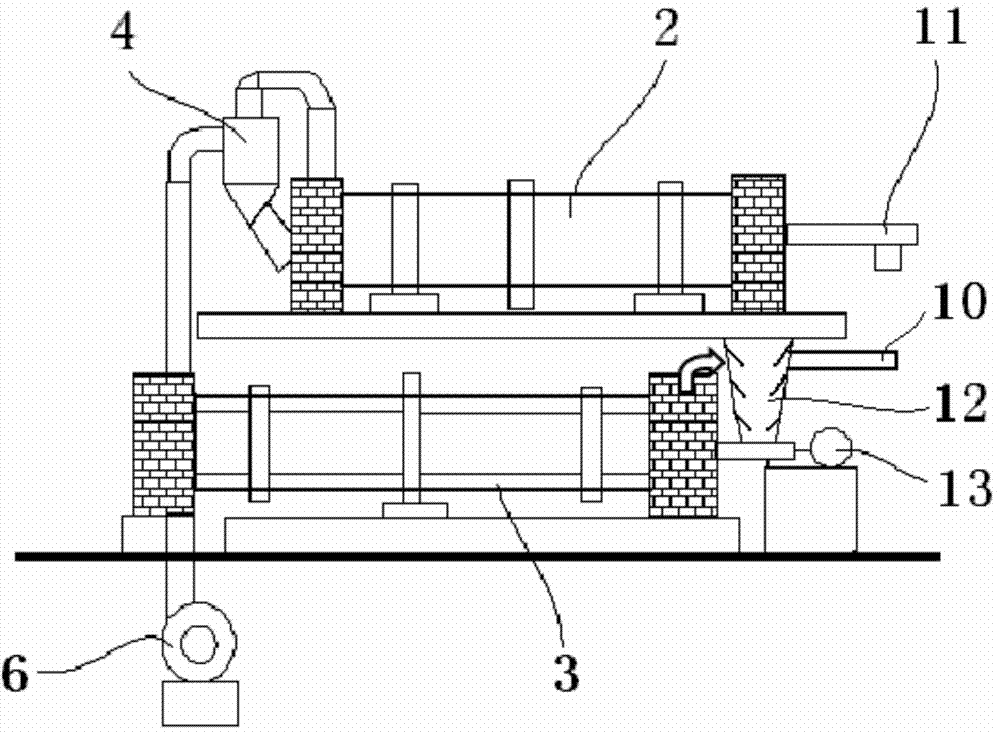

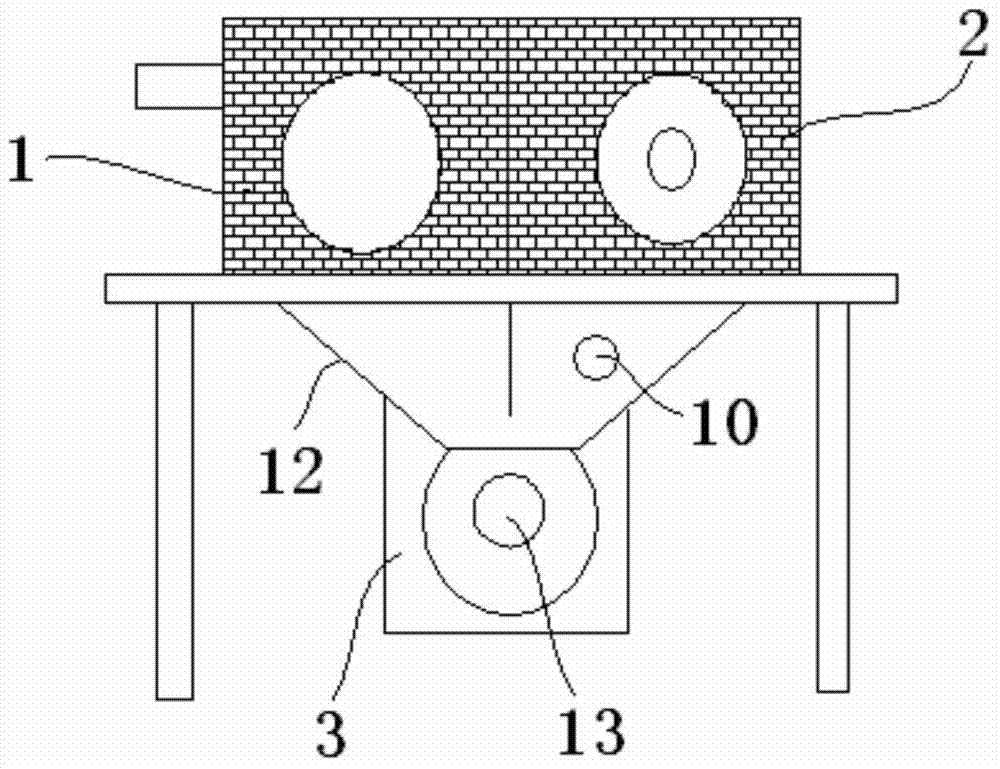

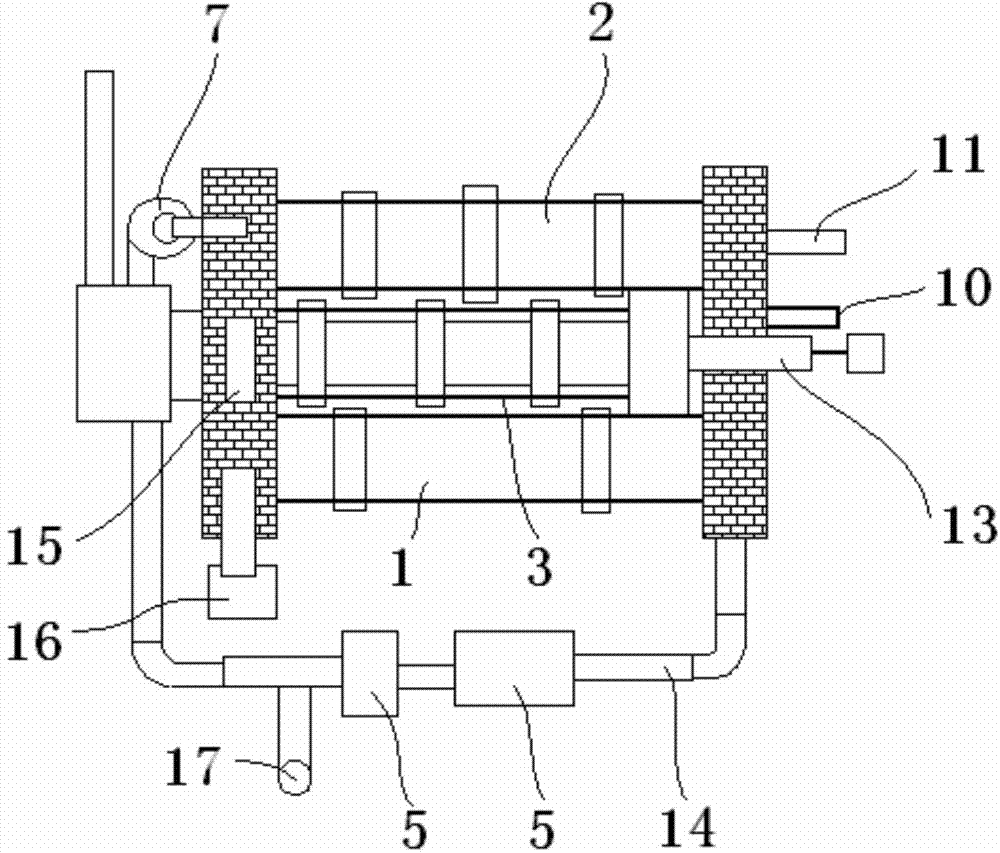

[0049] Following the technical solution of the present invention, the carbonization furnace 3 in this embodiment is an externally heated carbonization furnace, which is heated separately and the hot air inlet and outlet temperatures of the external heating type carbonization furnace 3 are respectively 1000°C and 1000°C. 600°C.

[0050] Combined with the above explanations, the working principle of the device is as follows:

[0051] (1) After the raw coal enters the raw coal preheating and drying furnace 1 through the raw coal bucket elevator 16 for drying and preheating, when the temperature of the raw coal reaches about 150-300°C, it enters the lower bin 12 and the 800-1000°C heat from the semi-coke heating furnace 2 The carrier, according to the ratio of 1: (1~2), is mixed and pushed into the external heating type carbonization furnace.

[0052] (2) After the preheated raw coal and the heated heat carrier exchange heat in the external heating type carbonization furnace 3 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com