Intelligent self-propelling belt-conveyor tail and application method thereof

A technology of belt conveyor and self-moving tail, which is applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of complex and cumbersome belts, belt deviation and wear, and ineffective effects, etc. Nursing, prevents severe wear, avoids tedious effects of the adjustment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following embodiments will further describe the present invention in conjunction with the accompanying drawings.

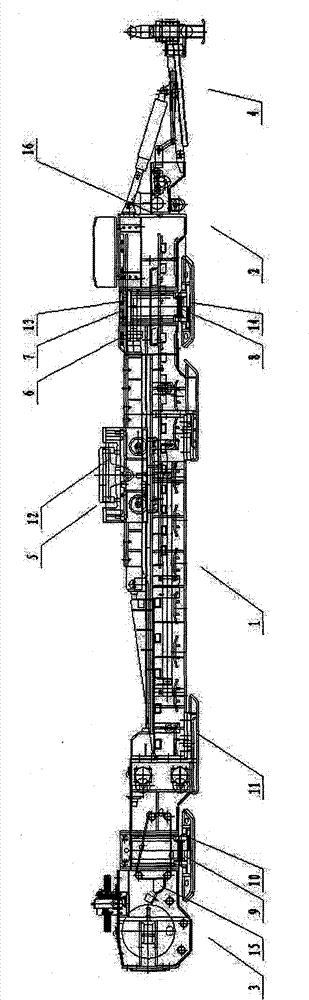

[0029] Such as figure 1 As shown, the intelligent belt conveyor self-moving tail, the main structure consists of the middle frame 1, the head end frame 2, the tail end frame 3, the floating frame 4, the traveling trolley 5, the push cylinder 6, the column cylinder 7, Horizontal oil cylinder 8, sliding shoe 9, sliding seat 10, and base composition 11; the right part of the middle frame 1 is connected to the head end frame 2, the head end frame 2 is connected to the floating frame 4, and the left part of the middle frame 1 is connected to the tail end frame 3. A traveling trolley 5 is provided on the upper part of the middle frame 1 and the head end frame 2; a sliding shoe 9, a sliding seat 10, a base 11, and a sliding seat 10 are provided on the lower parts of the head end frame 2 and the tail end frame 3 There is a column oil cylinder 7, and a horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com