Control device and method based on phase angle of phase current of direct-current brushless motor

A brushless DC motor and control device technology, applied in the direction of a single motor speed/torque control, electronic commutator, etc., can solve the problems of increasing reactive power and reducing the power factor of the input side, and reducing heat generation. , the effect of reducing network loss and reducing usage costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

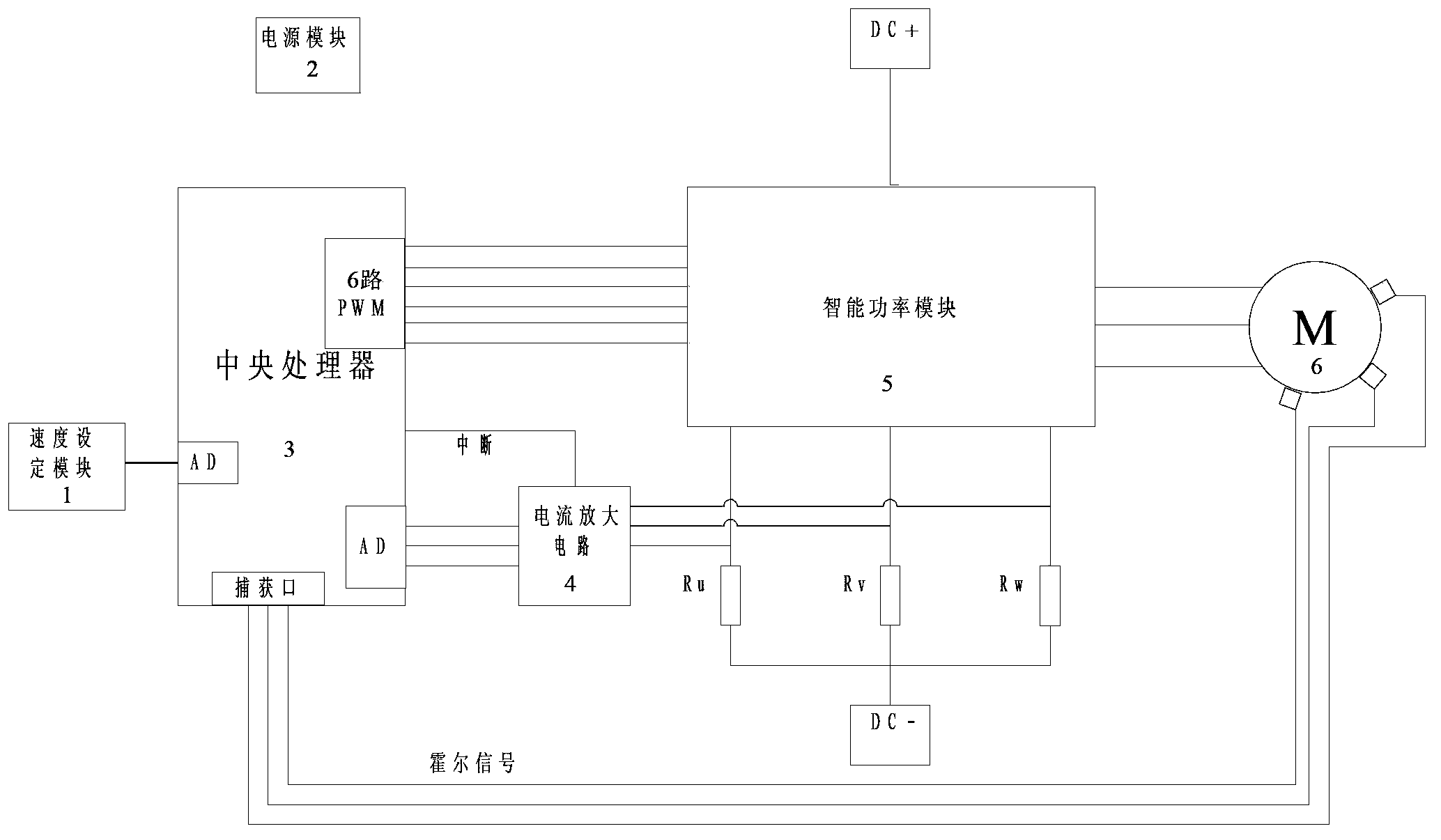

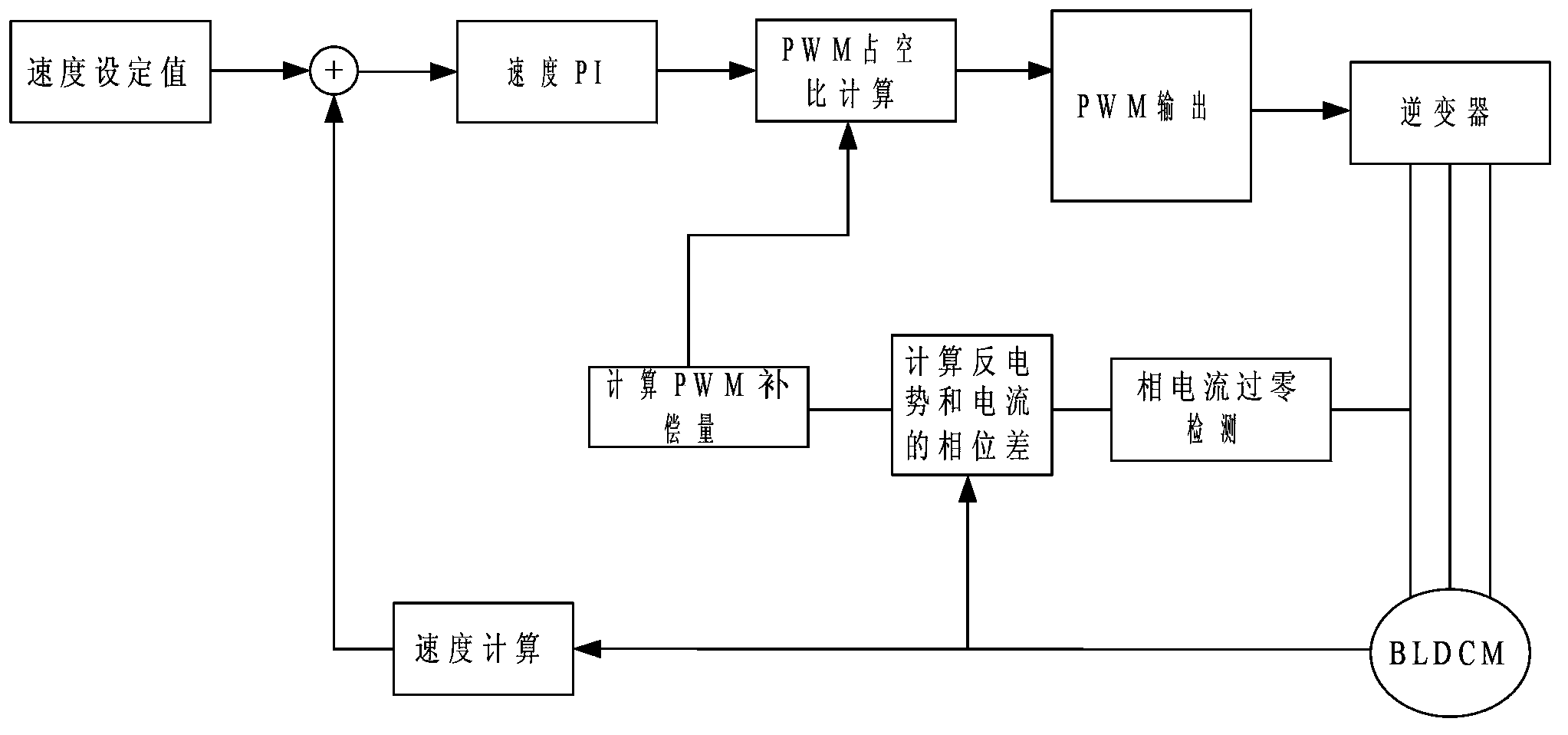

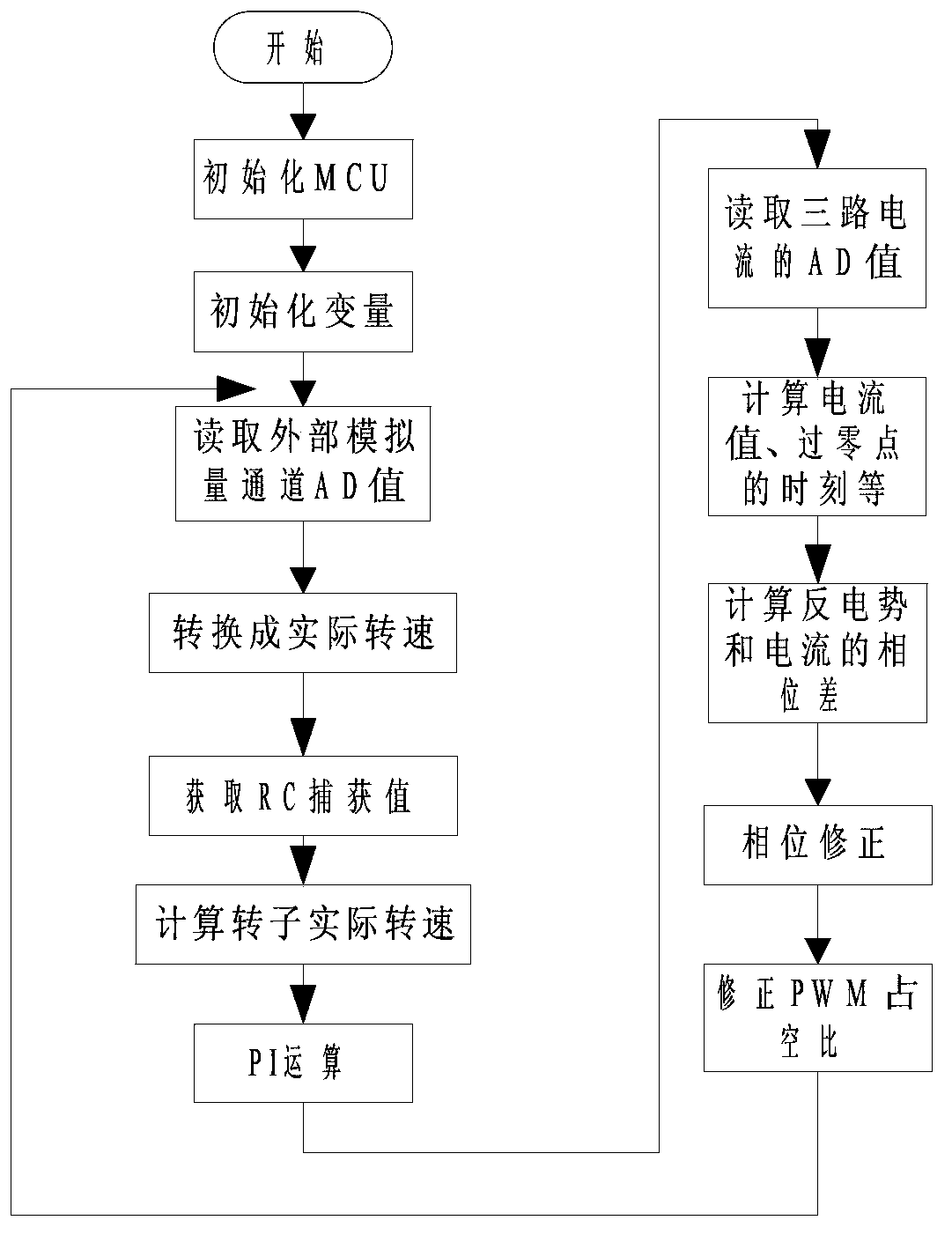

[0018] Such as figure 1 As shown, this high-efficiency control device based on the phase current phase angle of the brushless DC motor includes a speed setting module 1, a central processing unit 3, a current amplification circuit 4, an intelligent power module 5, a Hall sensor and a power supply module 2, and the central Processor 3 is 8-bit, and contains the following peripherals: 8-channel 10-bit AD converter, 6-way complementary PWM output with dead zone function, and a dedicated timer capture port. The CPU 3 includes 6 digital outputs, 4 analog inputs, 3 capture inputs, and 1 interrupt input. 6 channels of PWM include: three channels of PWM waves on the upper bridge arm and three channels of PWM waves on the lower bridge arm, respectively output to the intelligent power module 5; 4 channels of analog input include: 1 channel for speed setting, which is connected to the speed setting module 1 The remaining 3 channels are respectively used for the acquisition of the 3 phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com