Advanced fusion-fission subcritical energy source reactor core fuel assembly

A fuel assembly, subcritical technology, applied in the direction of fuel elements, reactor fuel materials, nuclear power generation, etc., can solve the problem of coolant pressure and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

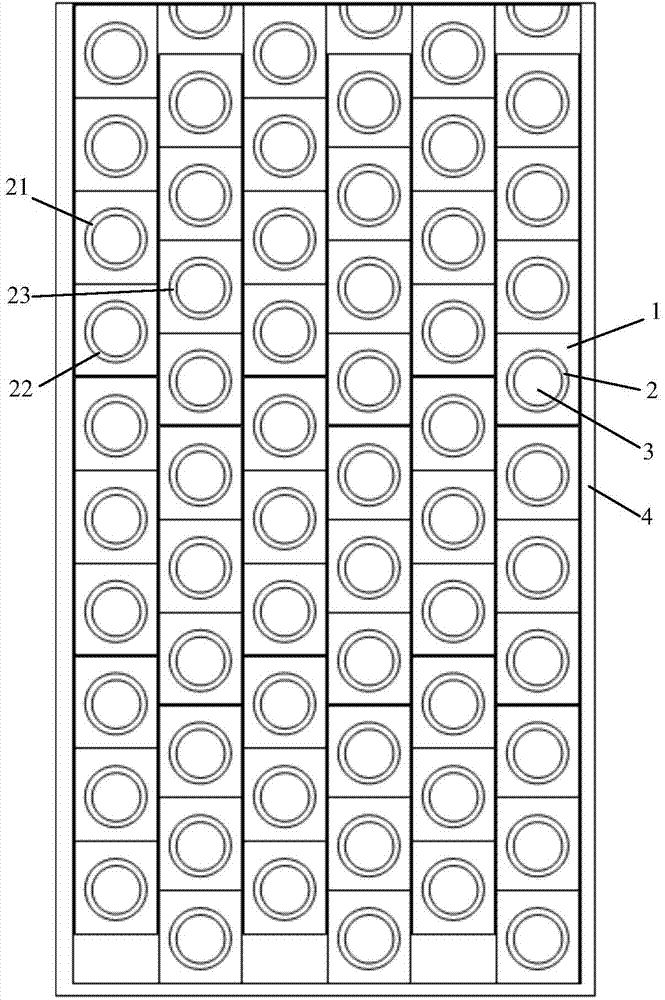

[0017] figure 1 A schematic diagram of the fuel assembly is given. The fuel assembly includes a multilayer structure arranged in sequence along the thickness direction, each layer structure includes several grid units arranged along the height direction, and each grid unit is composed of uranium-zirconium alloy fuel 1, water coolant 3 and cooling pipe 2 , the cooling tube 2 is used for bearing pressure and passes through the uranium-zirconium alloy fuel horizontally. The extension direction of the cooling tube is perpendicular to the thickness direction of the fuel assembly, and is arranged in an equilateral triangle in the fuel assembly, that is, three cooling tubes adjacent to each other in the fuel assembly The cross sections of the tubes 21, 22, 23 are equilateral triangles. Each fuel grid contains cylindrical cooling water 3, cylindrical zircon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com