Composite template for nano-imprinting and preparation method of composite template

A composite template and nano-imprinting technology, which is applied in the field of nano-imprinting, can solve the problems of high cost of electron beam direct writing technology, and achieve the effect of high binding energy and improved compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

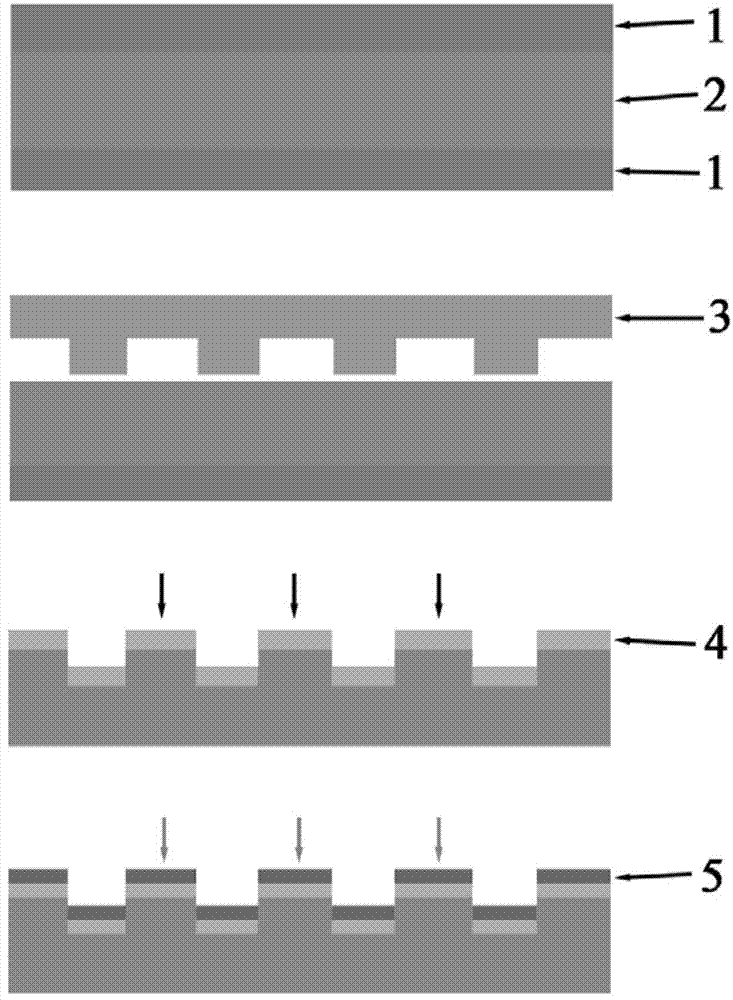

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0025] (1) Preparation of silica-elastomer composite template:

[0026] 1) The elastomer (take SEBS as an example) is made into a smooth and flat film by hot embossing:

[0027] a) Weigh 3.2g of elastomer, place it between two layers of clean PET films, place it in the chamber of the embosser, set the temperature at 200°C, and the pressure at 0.1MPa, and make the elastomer form a film by hot pressing;

[0028] b) Place the preliminarily formed film in the previous step between two 4-inch anti-adhesive silicon sheets, and heat press again to form a smooth elastomeric film.

[0029] 2) Use the nickel template obtained by electroplating to imprint to form a nano-lattice structure on the surface of the film:

[0030] The elastomer and the nickel template are closely attached, placed in the cavity of the imprinter, and the structure on the nickel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com