Pick-up lens

A camera lens and lens technology, applied in the field of camera lens, can solve the problem of the lens being not portable, and achieve the effect of short overall length of the lens, easy portability and good image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

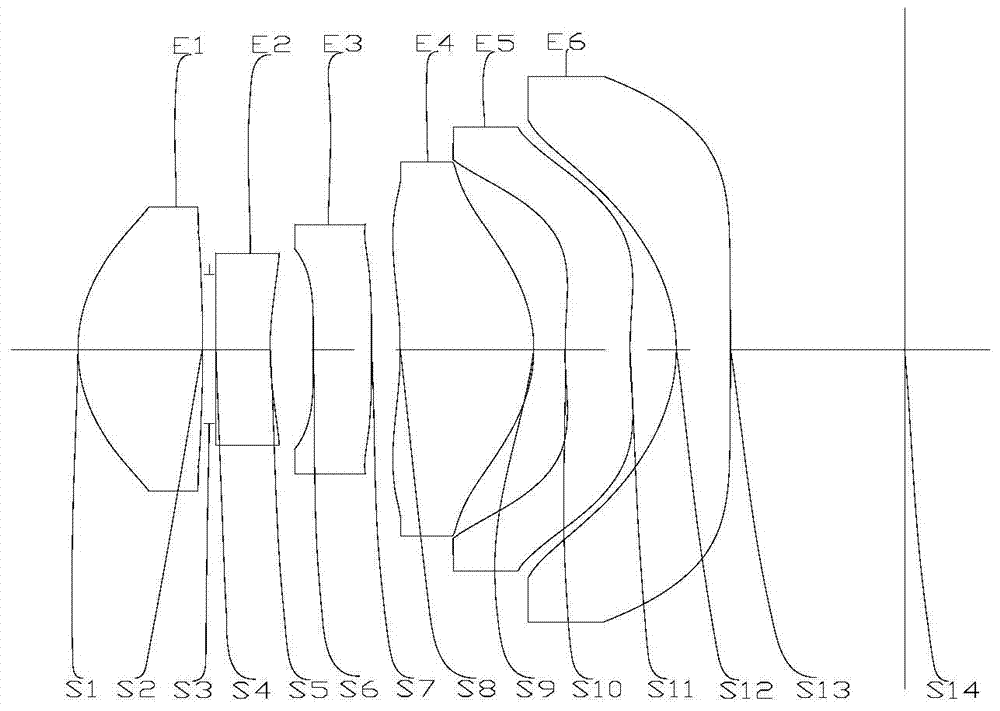

Image

Examples

Embodiment 1

[0035] The parameters of the camera lens in Example 1 are as follows: TTL=3.801; f1=2.278; f2=-4.565; f3=∞; f4=3.377; f5=-614.01; f6=-2.896; f=3.151;

[0036] Also satisfy: f4 / CT4=5.496; f2 / f4=-1.352; Yc41 / SD41=0.66,

[0037] Wherein, f4 is the focal length of the fourth lens; CT4 is the central thickness of the fourth lens on the optical axis; f2 is the focal length of the second lens; Yc41 is the inflection point on the object side surface of the fourth lens and the perpendicular to the optical axis distance; SD41 is the effective radius of the object-side surface of the fourth lens.

[0038] System parameters: 1 / 4" photosensitive device aperture value 2.4

[0039] Table 1

[0040] surface type Radius of curvature thickness Material Effective diameter Conic factor spherical endless endless Aspherical 1.3036 0.5725 1.544,56.11 1.8221 -0.2490 Aspherical -23.3857 0.0300 1.5191 -50.0000 spherical endless 0.03...

Embodiment 2

[0046] The parameters of the camera lens in Example 2 are as follows: TTL=3.81; f1=2.257; f2=-4.235; f3=136.48; f4=3.141; f5=-31.011; f6=-2.849; f=3.183;

[0047] Also satisfy: f4 / CT4=4.515; f2 / f4=-1.39; Yc41 / SD41=0.53,

[0048] Wherein, f4 is the focal length of the fourth lens; CT4 is the central thickness of the fourth lens on the optical axis; f2 is the focal length of the second lens; Yc41 is the inflection point on the object side surface of the fourth lens and the perpendicular to the optical axis distance; SD41 is the effective radius of the object-side surface of the fourth lens.

[0049] System parameters: 1 / 4" photosensitive device aperture value 1.9

[0050] table 3

[0051] surface type Radius of curvature thickness Material Effective diameter Conic factor spherical endless endless Aspherical 1.2427 0.4510 1.54,56.11 1.3264 0.2027 Aspherical -146.6670 0.0428 1.3438 -50.0000 Aspherical -102.8932 ...

Embodiment 3

[0058] The parameters of the camera lens in Example 3 are as follows: TTL=3.801; f1=2.471; f2=-3.321; f3=6.401; f4=3.418; f5=-85.018; f6=-2.796; f=3.117;

[0059] Also satisfy: f4 / CT4=4.986; f2 / f4=-0.972; Yc41 / SD41=0.672,

[0060] Wherein, f4 is the focal length of the fourth lens; CT4 is the central thickness of the fourth lens on the optical axis; f2 is the focal length of the second lens; Yc41 is the inflection point on the object side surface of the fourth lens and the perpendicular to the optical axis distance; SD41 is the effective radius of the object-side surface of the fourth lens.

[0061] System parameters: 1 / 4" photosensitive device aperture value 1.9

[0062] table 5

[0063]

[0064]

[0065] The following table is the aspheric high-order coefficients A4, A6, A8, A10, A12 of the aspheric lens,

[0066] Table 6

[0067]

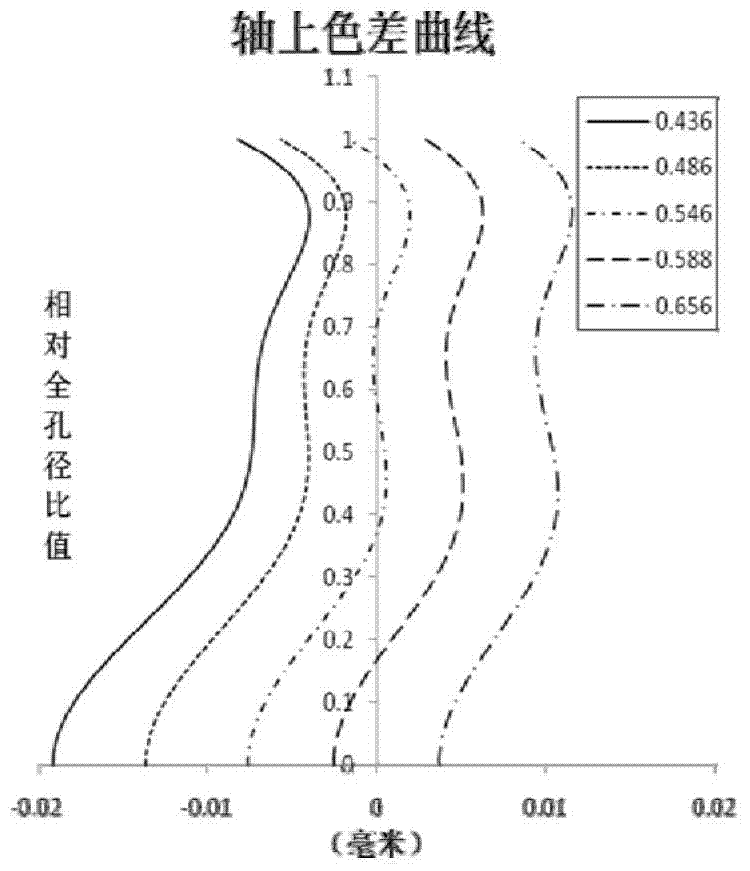

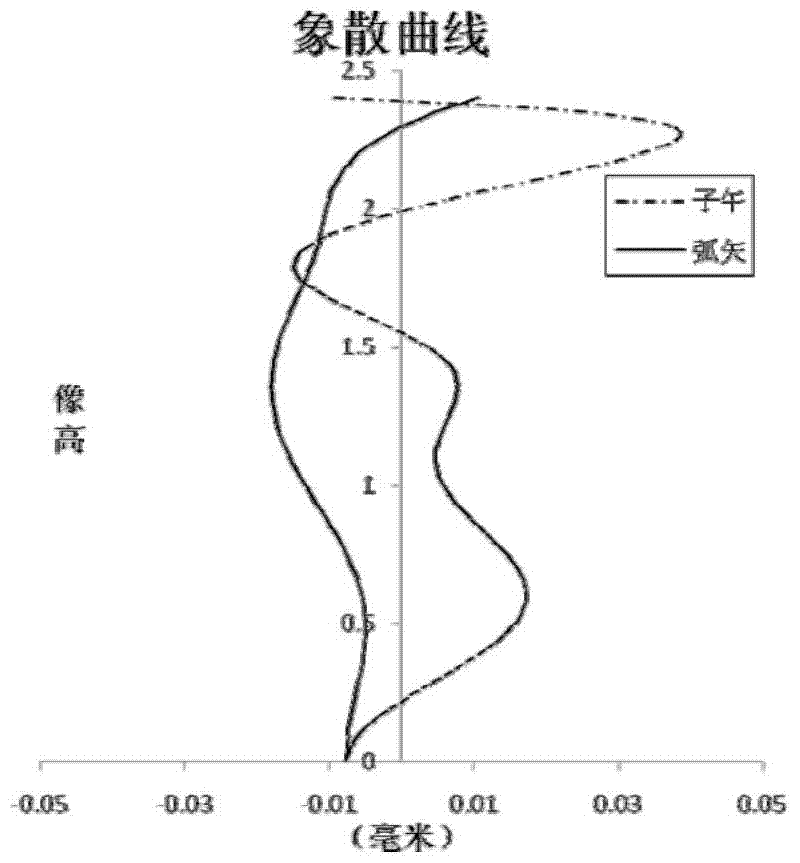

[0068] figure 2 , image 3 , Figure 4 and Figure 5 are the on-axis chromatic aberration diagram, astigmatism diagram, disto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com