Magnetohydrodynamic micropump

A technology of fluid mechanics and micropumps, which is applied in pumps, liquid variable displacement machines, machines/engines, etc., and can solve the problems of high manufacturing cost of MHD micropumps, large size of MHD micropumps, and three-dimensional electromagnet processing. Complicated problems, to achieve good suction efficiency, reduce processing and manufacturing costs, and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

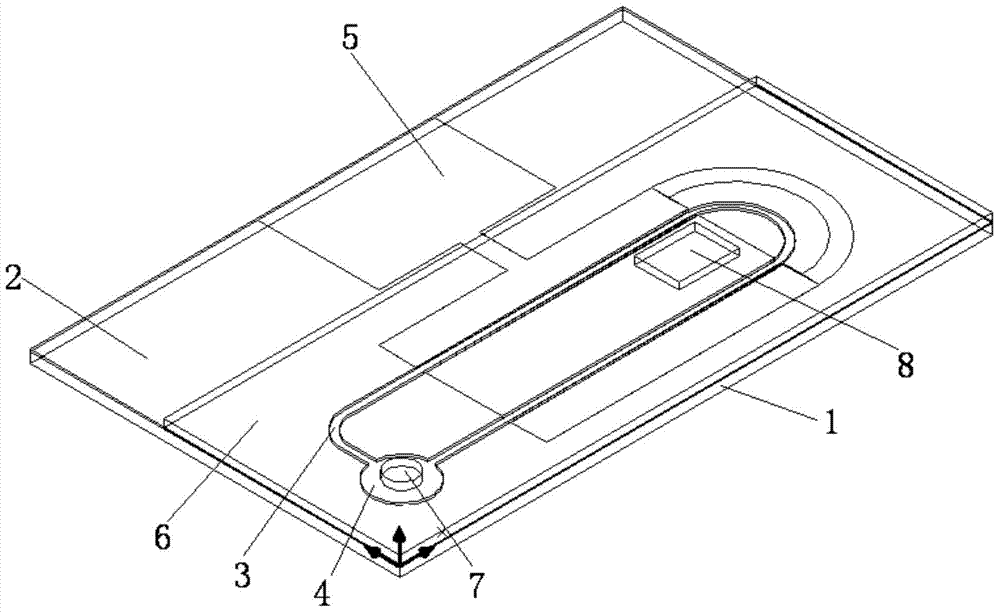

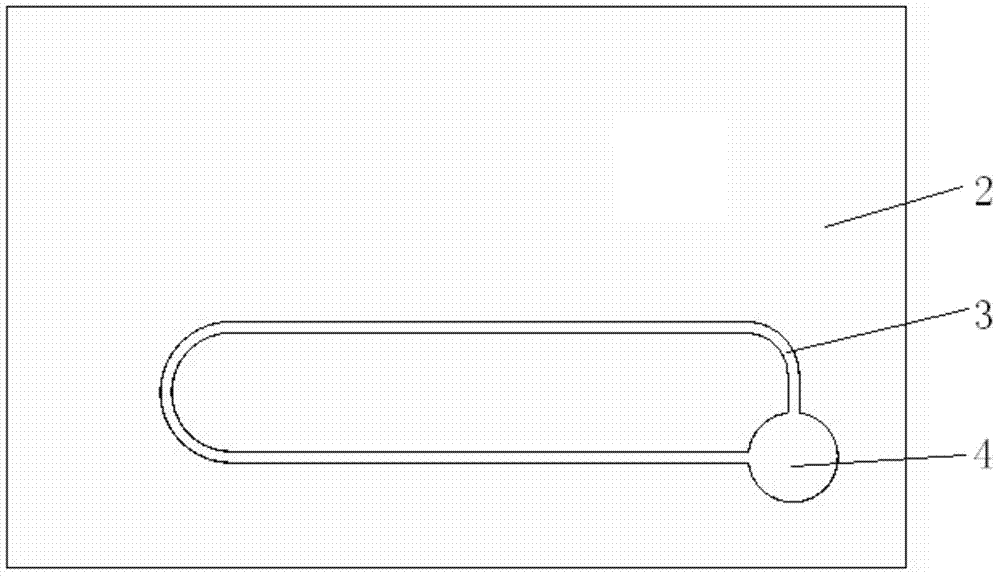

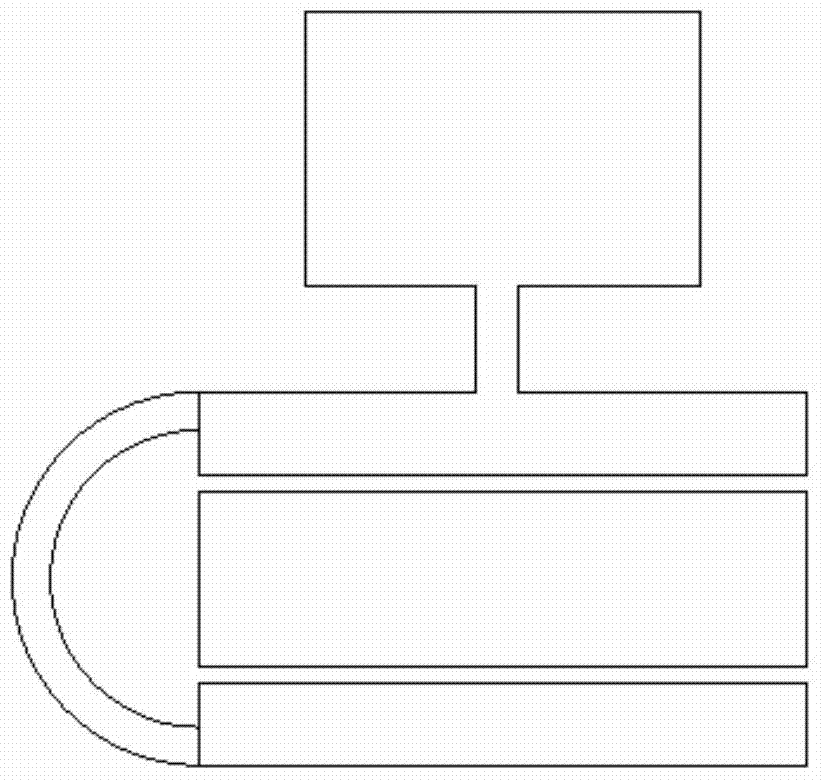

[0025] like Figures 1 to 6 As shown, the magnetohydrodynamic micropump includes a substrate 1, the lower surface of the substrate 1 is provided with a planar electromagnet, the upper surface of the substrate 1 is provided with a substrate 2, and microchannels are etched on the substrate 2. 3 and a reservoir 4 communicating with the microchannel 3, electrodes 5 are arranged on both sides of the microchannel 3, and the electrodes 5 are sputtered on the upper surface of the substrate 2, and an encapsulation layer for sealing the microchannel 3 is also included 6. The packaging layer 6 is provided with a liquid injection port 7 and an electrode access hole 8 for injecting liquid into the liquid reservoir 4 . The magnetohydrodynamic micropump adopts a planar electromagnet to generate a magnetic field instead of the existing three-dimensional el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com