Guardrail column with article insertion function

A technology of guardrail columns and guardrails, which is applied in the direction of fences, building structures, roads, etc., can solve the problems of relatively single installation location restrictions, inconvenient installation and removal, etc., and achieve the effect of satisfying aesthetics and practicality, large expansion and contraction deformation, and flexible location installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

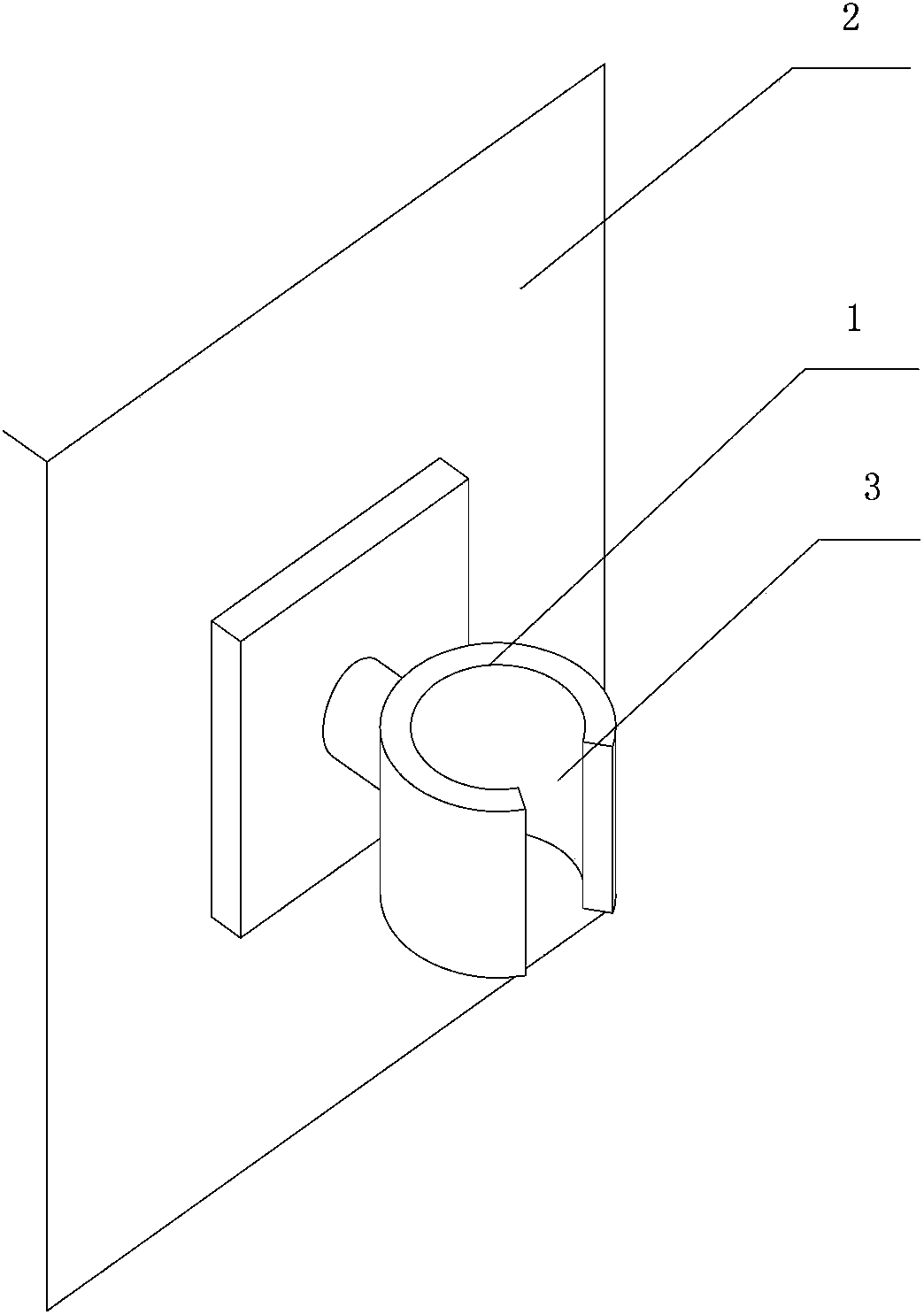

[0015] See figure 1 , the present invention provides an insertable guardrail column, which has a column body 2, and the column body 2 of the column of the guardrail has at least two elastically deformable clamping parts 1 that can be inserted. The cross-section of the clamping part 1 is an inverted U shape, and the top of the inverted U-shaped clamping part has an opening 3 facing outwards for insertion. The body 2 is fixedly connected.

[0016] Furthermore, the connection between the lower end of the side sections of the inverted U-shaped clamping member 1 and the column body 2 is very firm, stable in structure, and practical.

[0017] Further, the at least two clamping parts 1 are small and light, flexible in location and installation, and meet the requirements of aesthetics and practicality.

[0018] The further insertable clamping part 1 is made of elastic material, with large expansion and contraction deformation, which can meet the disassembly and installation requirem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com