A spheroidizing device for hollow microspheres

A hollow microbead and spheroidization technology, applied in glass molding, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of uneven compressive strength and uneven inner wall, achieve uniform compressive strength, improve physical properties, The effect of the spheroidization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

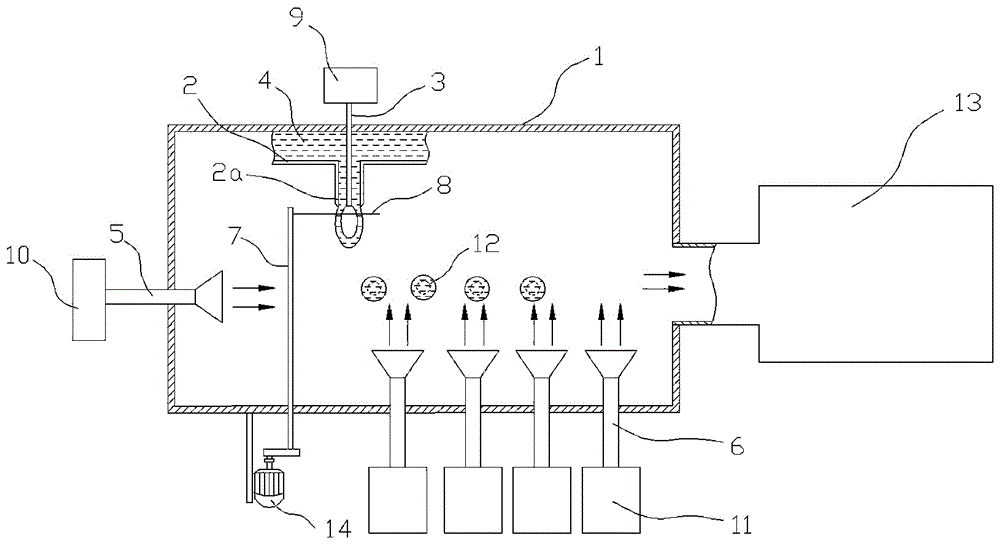

[0013] Such as figure 1 As shown, the spheroidization device of a kind of hollow microsphere provided by the present invention comprises a spheroidization chamber 1, a solution tank 2 is arranged on the inside of the spheroidization chamber 1, and an outlet 2a is provided below the solution tank 2, and an outlet 2a is arranged on the solution tank 2. Melt liquid 4 is provided in the tank, and an air intake pipe 3 is also provided in the solution tank 2. One end of the air intake pipe 3 is matched with the outlet 2a, and the other end is connected with the upper air source 9 arranged outside the spheroidizing chamber. One side of the chemical chamber 1 is also matched with a collector 13, which is characterized in that:

[0014] a. A rotating shaft 7 is vertically connected in the spheroidizing chamber 1. A through hole is arranged on the upper end of the rotating shaft 7, and a cutter 8 is inserted in the through hole. The rotating shaft 7 and the cutter 8 are locked by screws...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com