A method for macro-scale preparation of graphene and two-dimensional boron nitride crystal materials

A two-dimensional crystal and graphene technology, applied in graphene, chemical instruments and methods, nitrogen compounds, etc., can solve problems such as difficult preparation of two-dimensional boron nitride nanomaterials, and achieve high product purity, promotion of stripping, and low price cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh 0.1 g of flake graphite and 0.05 g of ammonia borane (NH 3 BH 3 ) in a ball mill jar, and milled on a planetary ball mill at 50°C, the medium balls are steel balls, the mass ratio of balls to materials during the milling process is 50:1, the rotational speed is 200 rpm, and the milling time is 1 hour. The obtained product is fully washed with ethanol, the obtained suspension is filtered, and then dried at 50 degrees to obtain the graphene material. Ethanol was distilled off from the filtrate under reduced pressure to recover white ammonia borane solid.

Embodiment 2

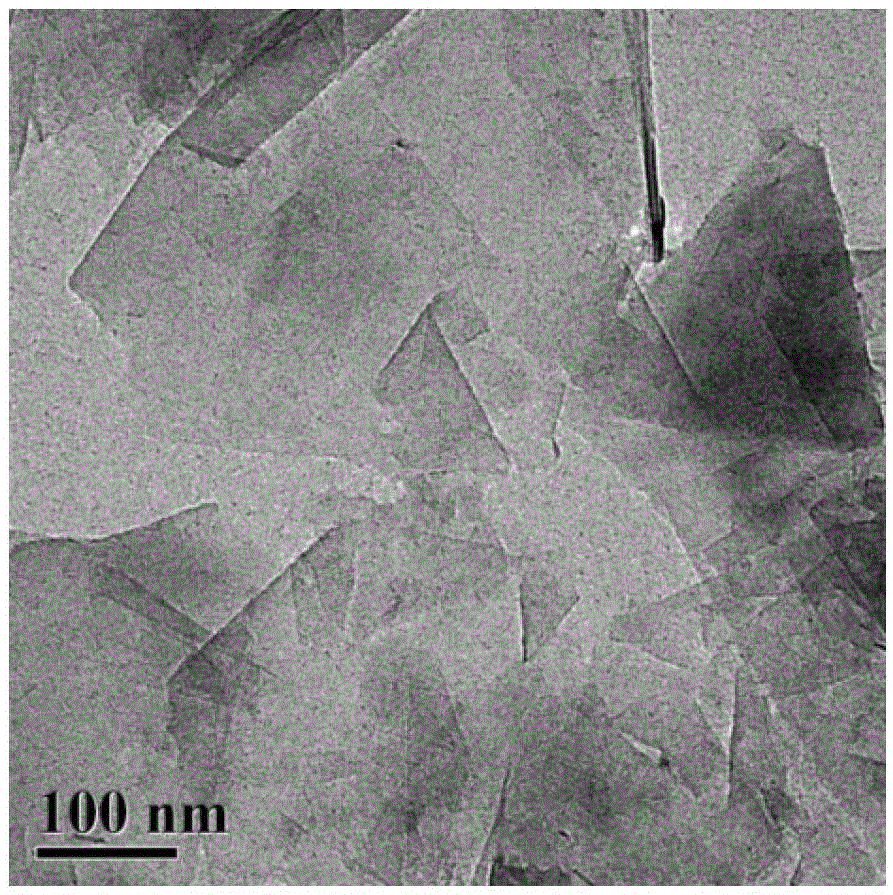

[0034] Weigh 0.1 g of expandable graphite and 0.1 g of ammonia borane (NH 3 BH 3) in a ball mill jar, and milled on a planetary ball mill at room temperature, the medium balls are steel balls, the mass ratio of balls to materials during the milling process is 500:1, the rotational speed is 150 rpm, and the milling time is 4 hours. The obtained product is fully washed with methanol, and the obtained suspension is filtered and then dried at 60 degrees to obtain a graphene material, and its transmission electron microscope photo is as follows: figure 1 shown. The filtrate is distilled off under reduced pressure to remove methanol, and the white ammonia borane solid can be recovered.

Embodiment 3

[0036] Weigh 0.1 g of expanded graphite and 0.3 g of ammonia borane (NH 3 BH 3 ) in a ball mill jar, and milled on a planetary ball mill at room temperature, the medium balls are steel balls, the mass ratio of balls to materials during the milling process is 200:1, the rotational speed is 150 rpm, and the milling time is 4 hours. The obtained product is fully washed with deionized water, the obtained suspension is filtered, and then dried at 60 degrees to obtain a graphene material. The filtrate is distilled off under reduced pressure to remove deionized water, and the white ammonia borane solid can be recovered. Raman spectroscopy results show that the obtained graphene material has a wavenumber of 2696cm -1 The G' peak, the symmetrical peak shape shows that the obtained graphene is of good quality. High-resolution transmission electron microscopy test results show that the obtained graphene has single-layer graphene and multi-layer graphene. The number of multi-layer grap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com