Vertical type winding machine for metal wires

A metal wire, winder technology, applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of reducing production efficiency, unstable work, increasing unloading time, etc. Ease of work effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

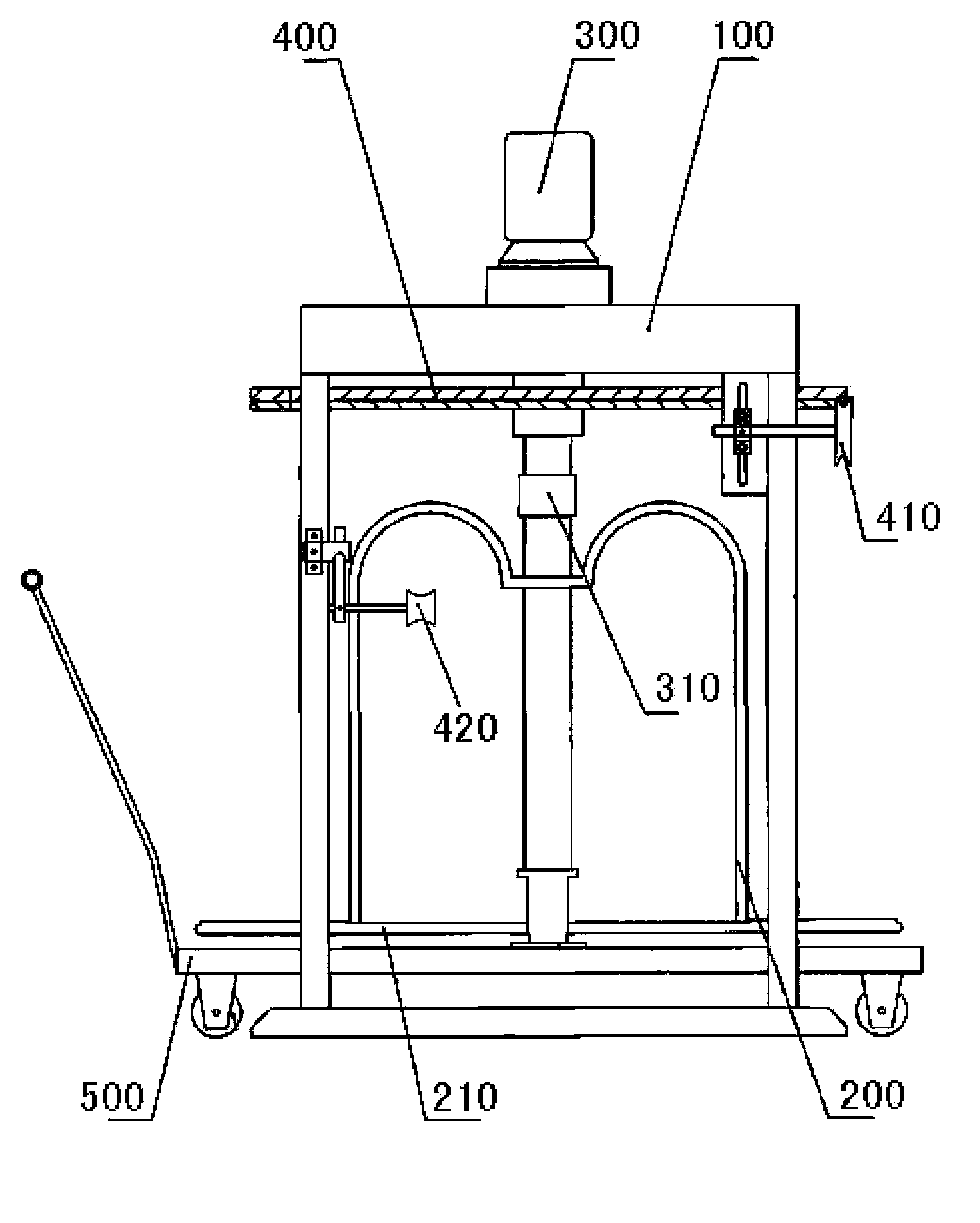

[0014] see figure 1 , a vertical winding machine for metal wire, including a bracket 100 and a winding reel 200, a driving mechanism 300, a guide plate 400 and a trolley 500, the driving mechanism 300 is arranged on the bracket 100, and the guide plate 400 is arranged on the driving mechanism 300 On the output shaft of the drive mechanism 300, a looper coupling 310 is arranged on the top of the output shaft of the driving mechanism 300, and the winding reel 200 is connected with the output shaft of the driving mechanism 300 through the looper coupling 310, and the winding reel 200 is arranged on the cart 500 on.

[0015] The driving mechanism 300 includes a torque motor and a reducer, the torque motor is connected to the reducer, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com