System and method for remote fault diagnosis of conveying belt

A technology for fault remote diagnosis and conveyor belt, which is applied in the direction of conveyor objects, conveyor control devices, transportation and packaging, etc. It can solve problems such as fault diagnosis, long processing time, affecting the normal operation of the conveyor belt, and paper company losses, etc., to achieve Effect of Shortening Troubleshooting Time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

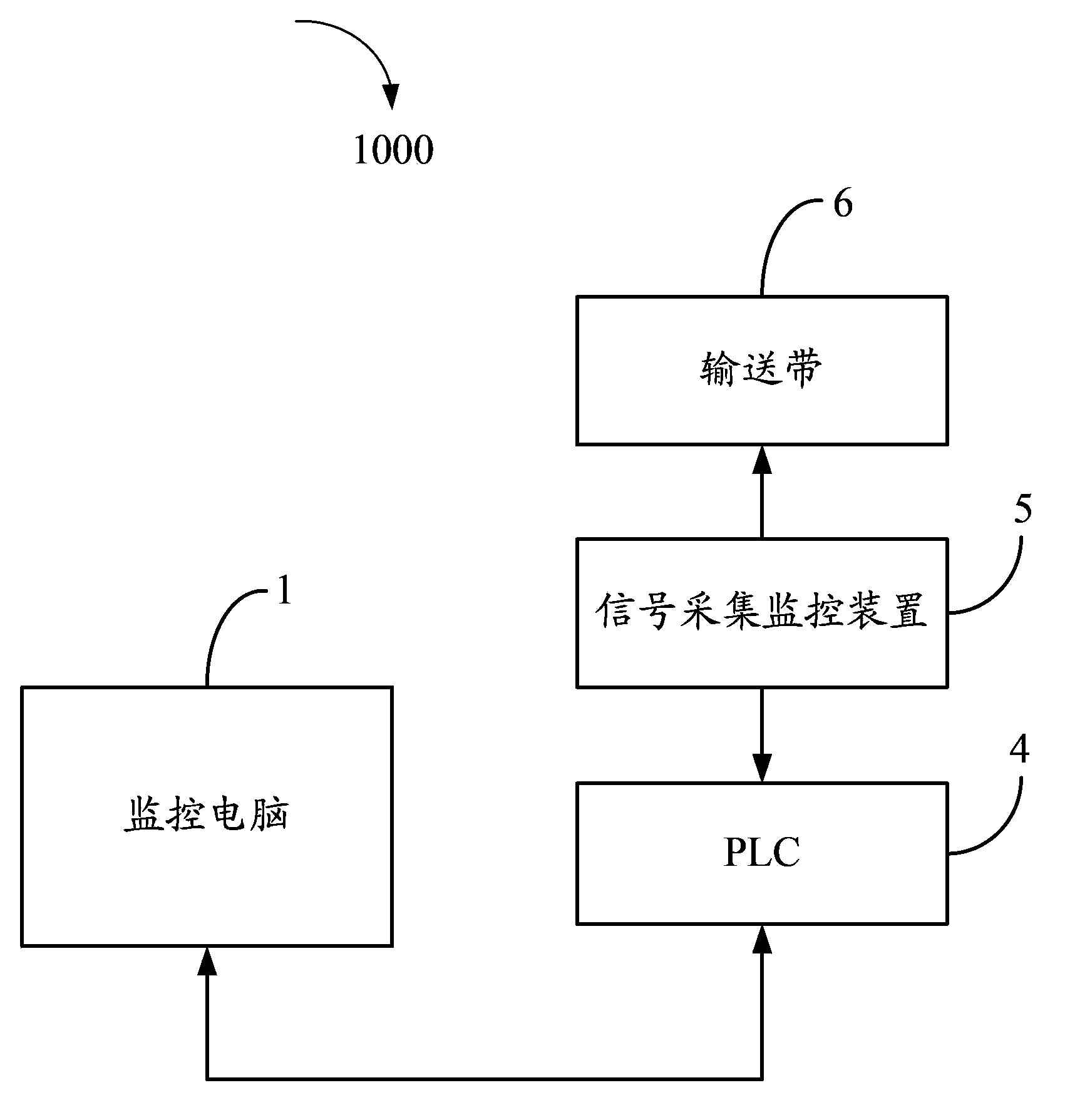

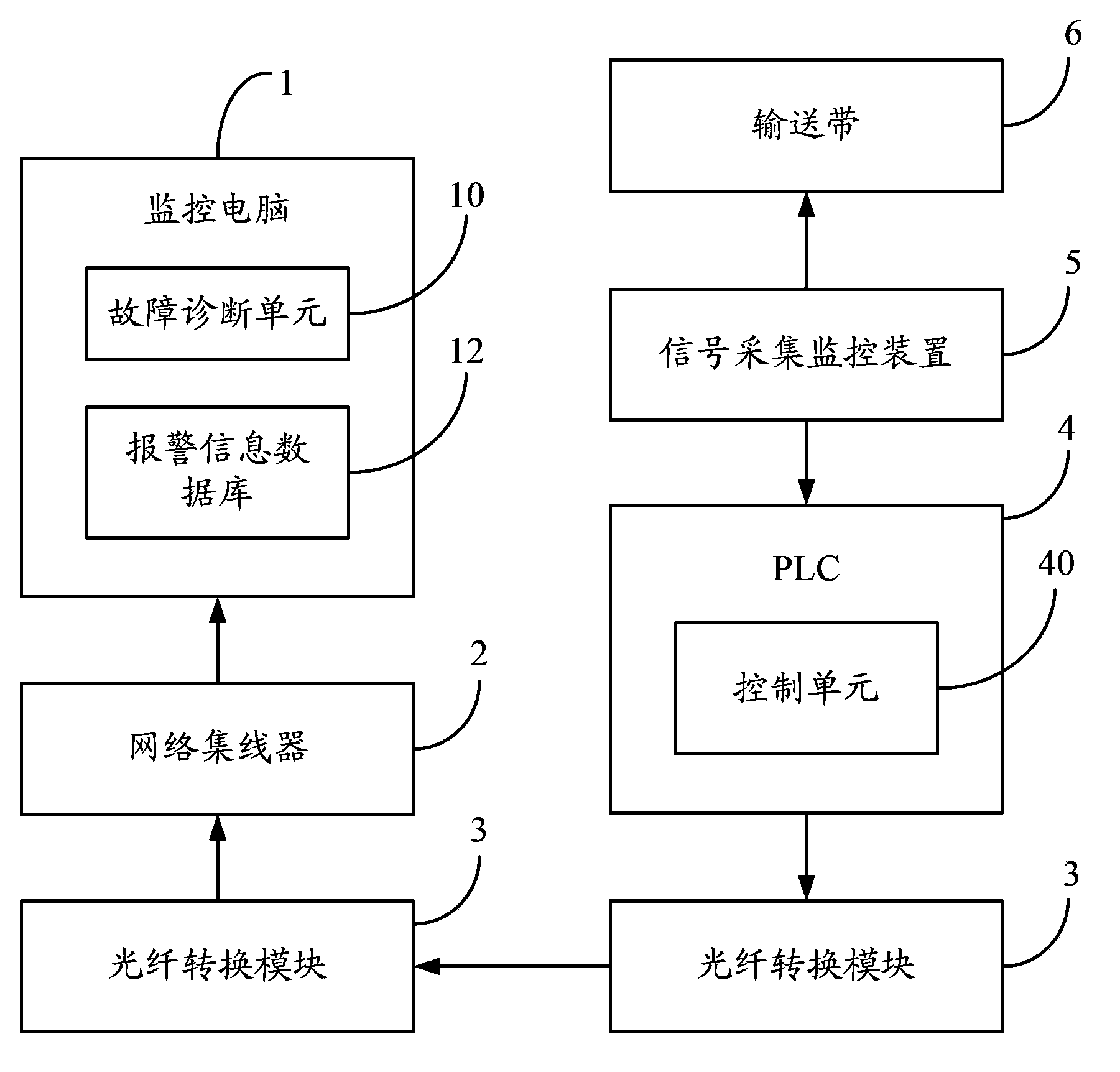

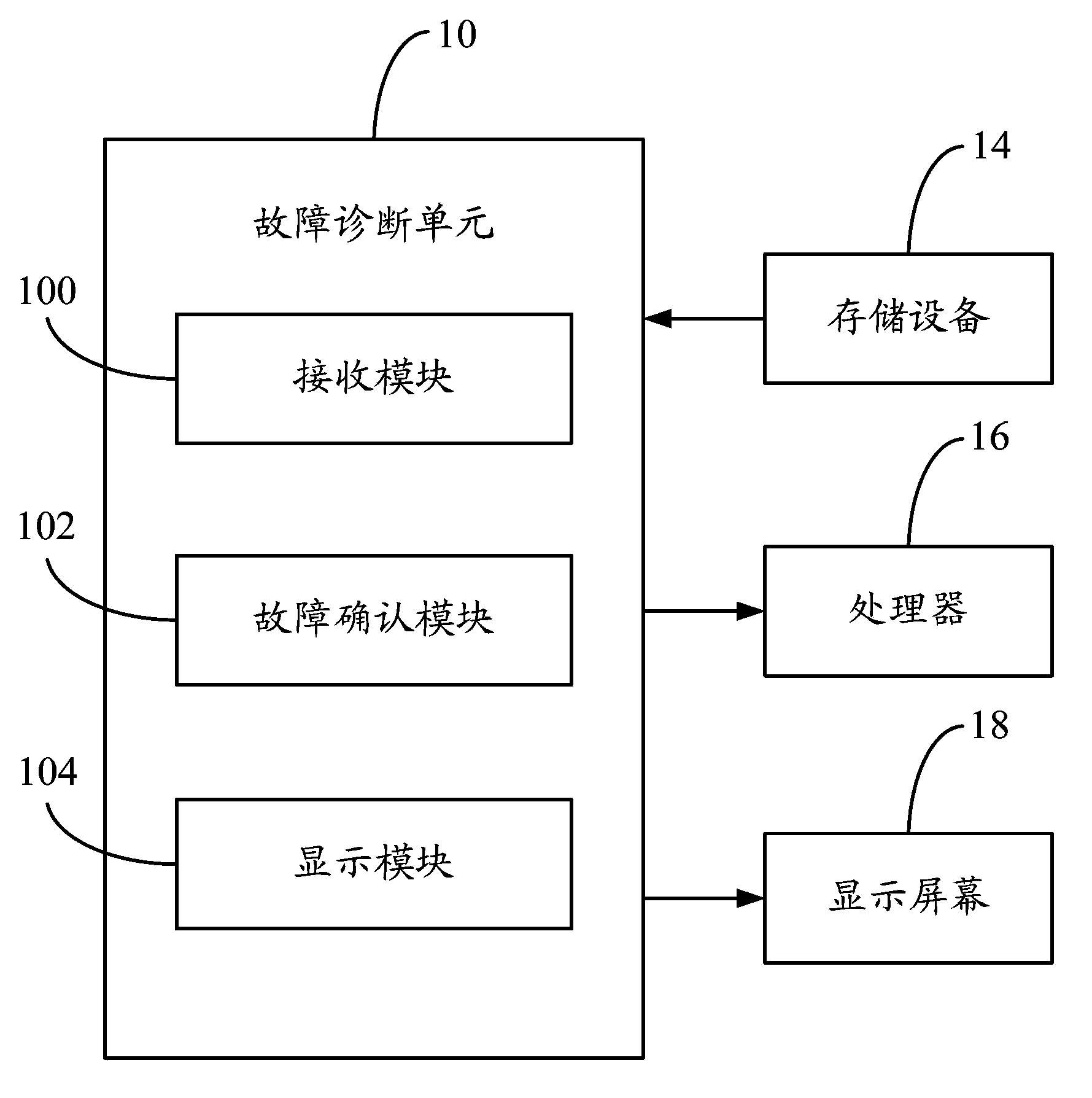

[0016] Such as figure 1 As shown, it is a structural schematic diagram of the conveyor belt fault remote diagnosis system 1000 of the present invention. The conveyor belt fault remote diagnosis system 1000 includes a monitoring computer 1 , a programmable logic controller (programmable logic controller, PLC) 4 (hereinafter collectively referred to as “PLC4”) and a signal acquisition and monitoring device 5 . The PLC4 is used to control the operation of the conveyor belt 6 . The signal collection and monitoring device 5 is used to monitor the running state of the conveyor belt 6, and collect the running state signal of the conveyor belt 6, such as collecting the running signal and / or output signal of each hardware related to the operation of the conveyor belt 6, the Hardware includes sensors, frequency converters, bus communication modules, contactors and relays. The monitoring computer 1 is used for remote diagnosis of the location and cause of the failure of the conveyor be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com