Material selecting and manufacturing method of integral baling steel wire knot

A technology of packing steel wire and one-piece type, which is applied in the field of metal product manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

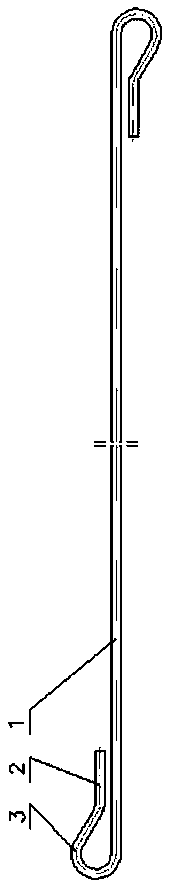

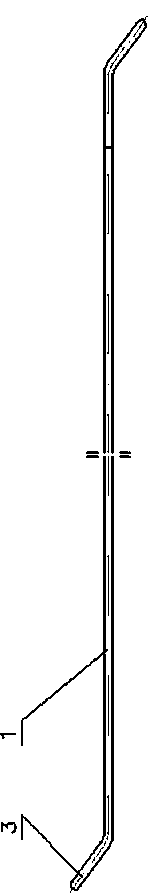

[0008] The selection model is: 72B, the specification is the alloy spring steel coil wire rod of ¢6.5mm as the manufacturing material of the present invention. According to the processing process: 72B specification wire coils are pickled, phosphating, cold drawn, galvanized, and then attached figure 1 and 2 For the buckle shape and bending angle shown, the buckle 3 and the buckle tail 2 at both ends of the steel wire body 1 are bent and formed, and the final inspection→packaging→storage can be done.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com