Feeder assembly with rough and fine feeding channels

A technology of feeding channels and feeders, which is applied in the direction of solid materials, packaging, and types of packaging items, can solve problems such as difficulty in ensuring accuracy, unadjustable feeding speed, and affecting packaging quality and company benefits, so as to maintain reputation and benefit, improve the quality of packaging, the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

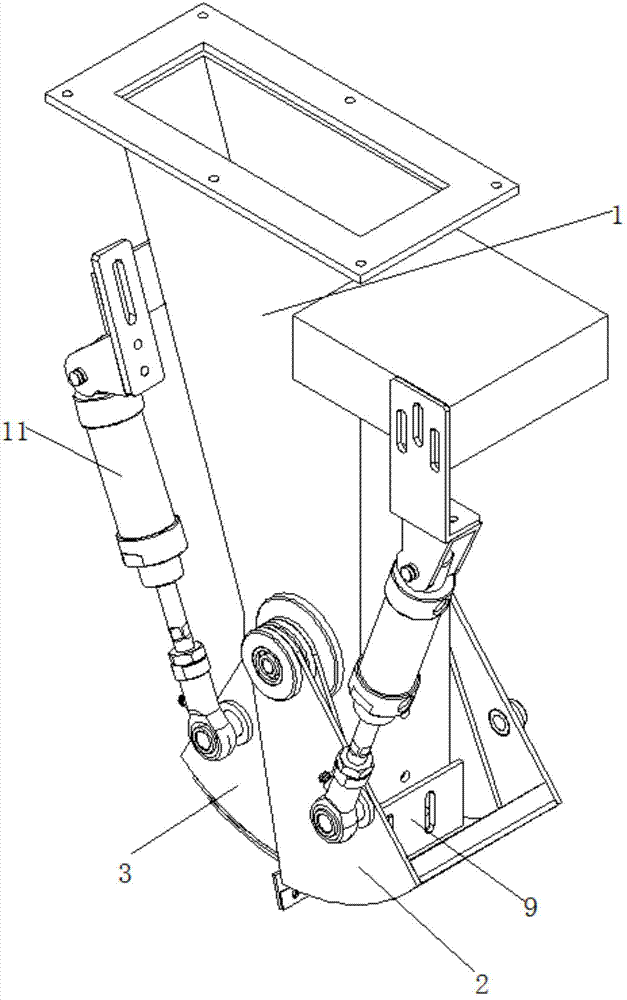

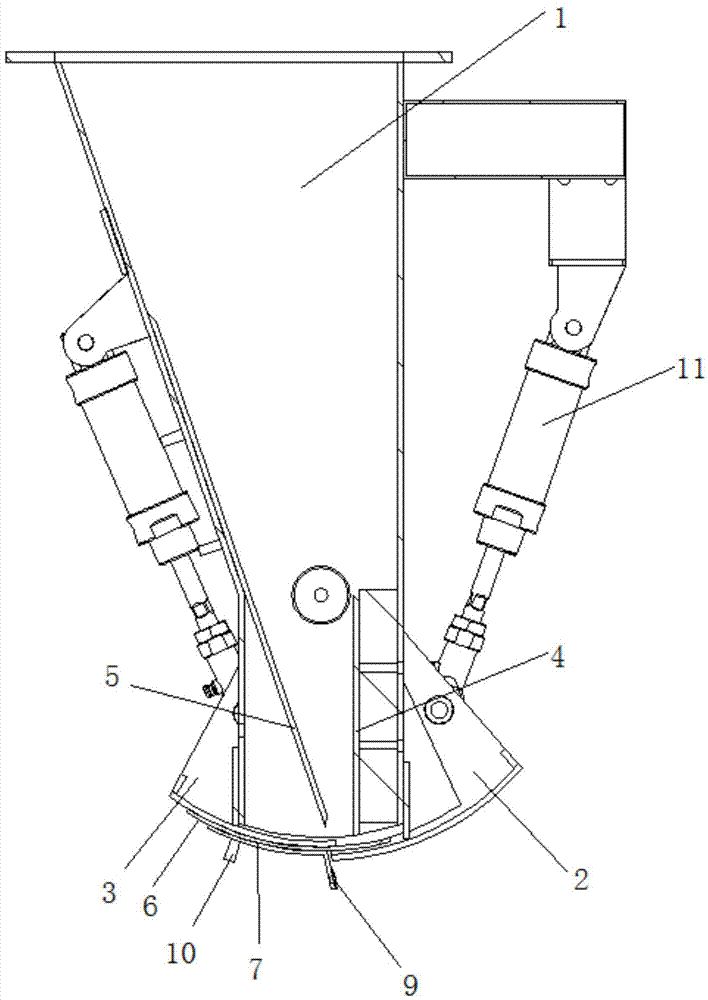

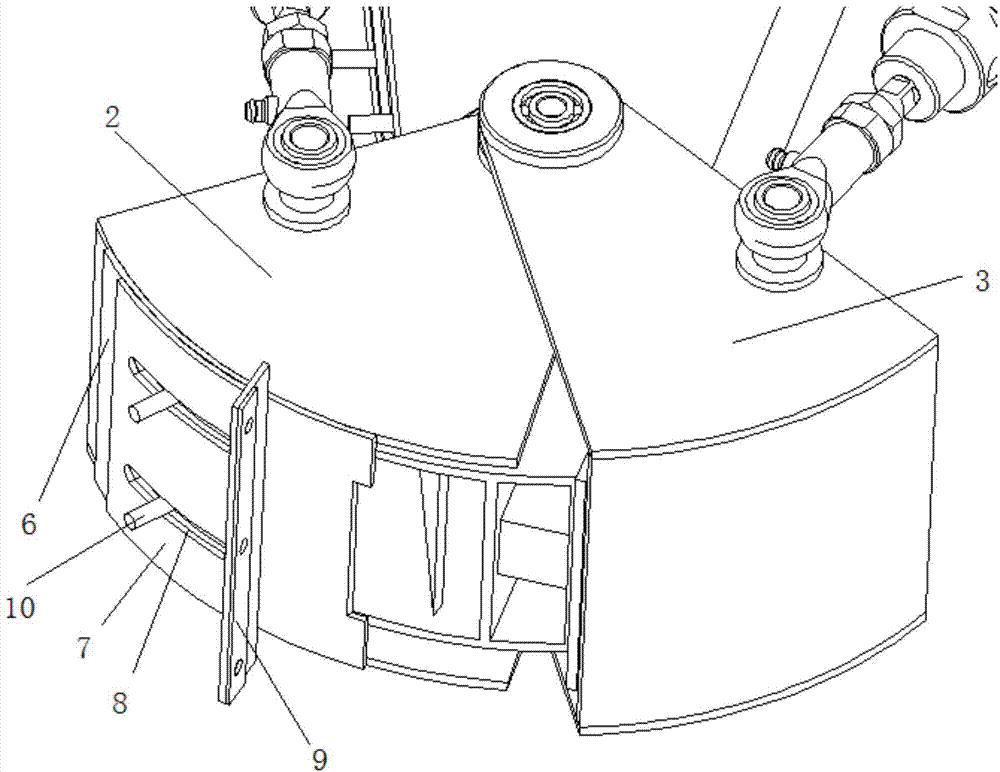

[0014] Referring to the accompanying drawings, a feeder assembly with a thick and thin feed channel includes a discharge pipe 1, and the bottom end of the discharge pipe 1 is installed with a coarse feed gate 2 and a fine feed gate 2 that are aligned with each other through a rotating shaft. The gate 3 and the fine feed gate 3 are located on the outside of the coarse feed gate 2, and the fine feed gate 3 is provided with a partition 4 in the discharge pipeline 1 above it, and the coarse feed gate 2 corresponds to the discharge pipe above it. The pipeline 1 is equipped with a coarse feeding adjustment plate 5, which is installed on the side wall of the discharge pipeline 1 through bolts and can be tilted and adjustable. The fine feed pipe adjustment plate 6 at the mouth, the fine feed pipe adjustment plate 6 is an arc plate, the fine feed pipe adjustment plate 6 is provided with a fixed plate 7, and the fixed plate 7 is provided with a waist-shaped adjustment hole 8 and a limit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com