Diaphragm laser cutting device

A laser cutting and membrane technology, applied in auxiliary devices, laser welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of waste of copper plate, high production cost, lower product qualification rate, etc., to reduce friction, cutting, etc. The effect of high precision and reduced chance of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0025] The technical scheme of concrete implementation of the present invention is:

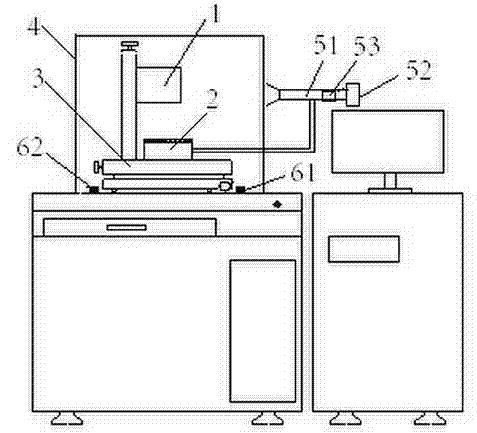

[0026] Such as figure 1 As shown, a diaphragm 8 laser cutting device includes a laser generator 1 for cutting out a diaphragm 9 monomer on the diaphragm 8, a positioning tool 2 for fixing the diaphragm 8, and a positioning tool for adjusting 2 a position adjustment mechanism 3 relative to the laser generator 1;

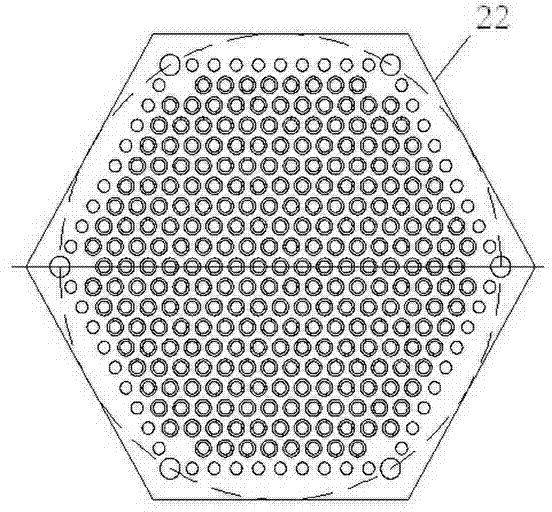

[0027] The positioning tool 2 includes a bin body 21 with an open top and a flat carrier plate 22 that closes the top opening of the bin body 21; Dimple 23, the bottom surface of the dimple 23 is provided with a through hole 24 connected to the lower surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com