Welding source output control method

A welding power source and output control technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of unable to reduce output, long arc period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

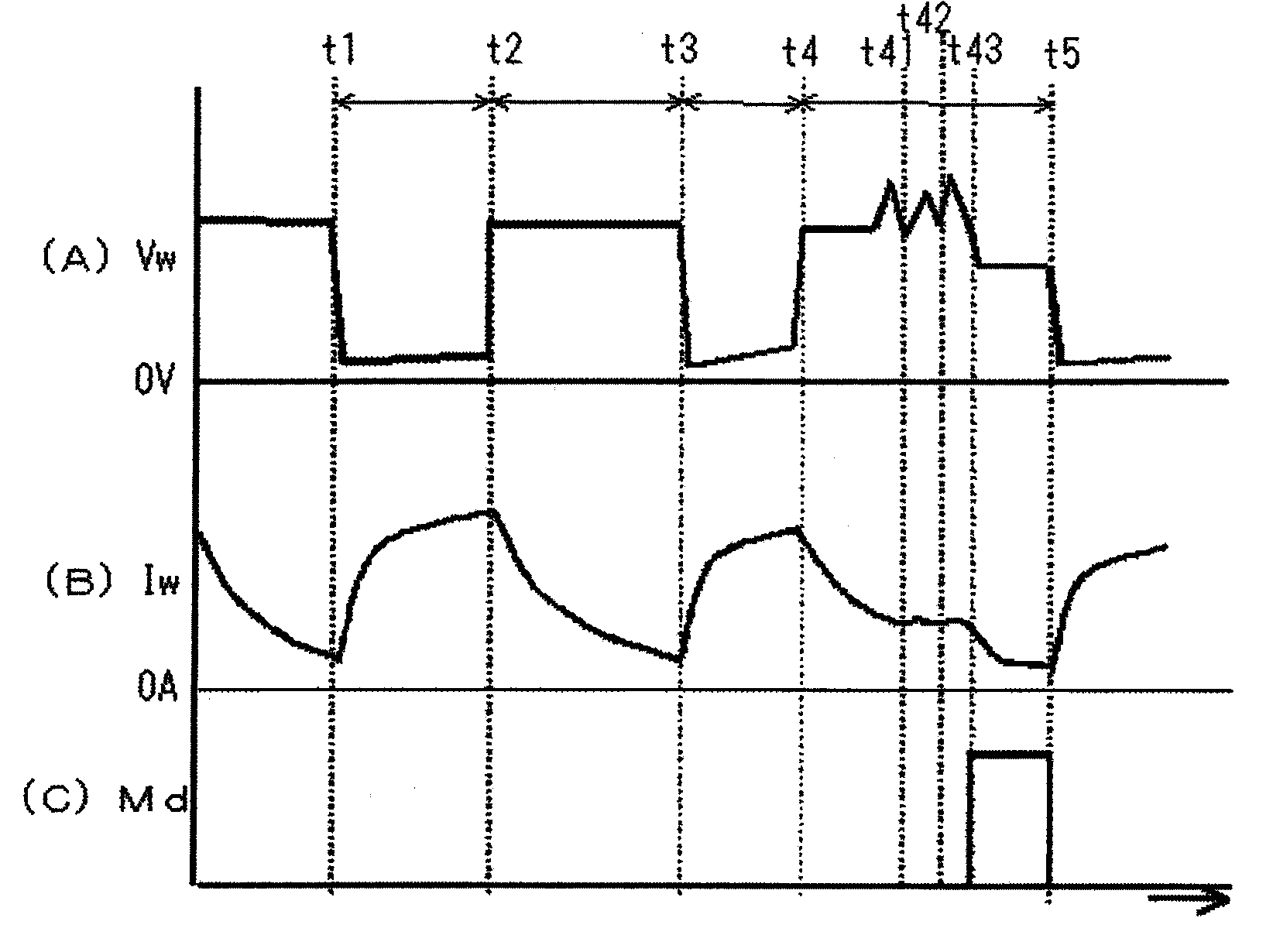

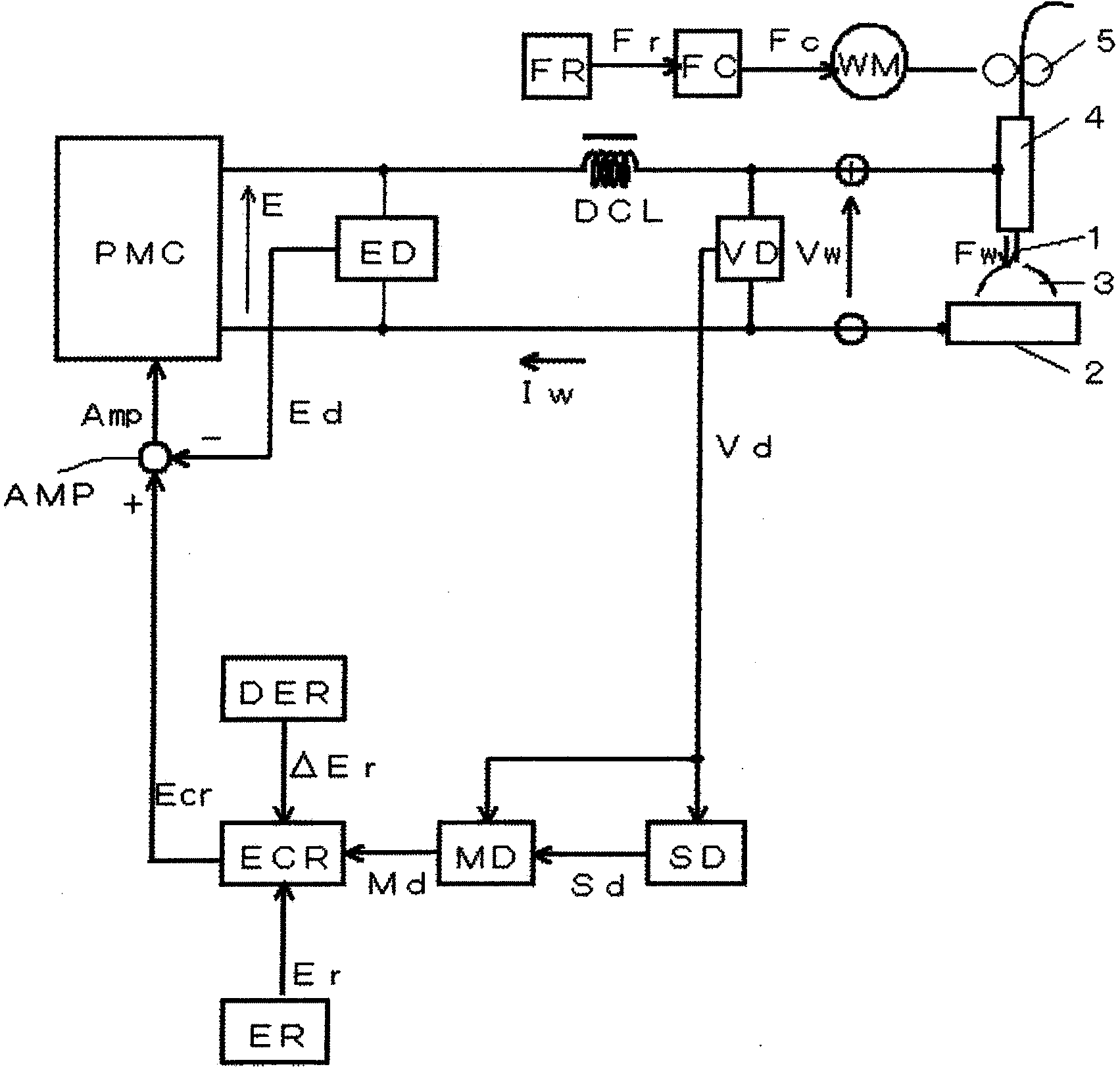

[0062] figure 1 It is a voltage / current waveform diagram which shows the output control method of the welding power supply concerning Embodiment 1 of this invention. figure 1 (A) represents the waveform of the welding voltage Vw, figure 1 (B) represents the waveform of the welding current Iw, figure 1 (C) shows the waveform of the droplet state determination signal Md. figure 1 corresponding to the above Figure 5 , is the case of carbon dioxide arc welding with an average welding current of 230A. figure 1 Indicates a 2-cycle waveform. During the period from time t1 to t3, there is no gas ejection from the molten pool, and the welding state is stable, and during the period from time t3 to t5, gas ejection from the molten pool occurs. The above-mentioned droplet state determination signal Md is a signal that becomes High level when it is determined that the droplet is in a state of being pushed upward. exist figure 1 In , the feeding speed of the welding wire is al...

Embodiment approach 2

[0080] In the invention of the second embodiment, the feeding speed of the welding wire is increased in synchronization with the reduction of the welding current of the first embodiment.

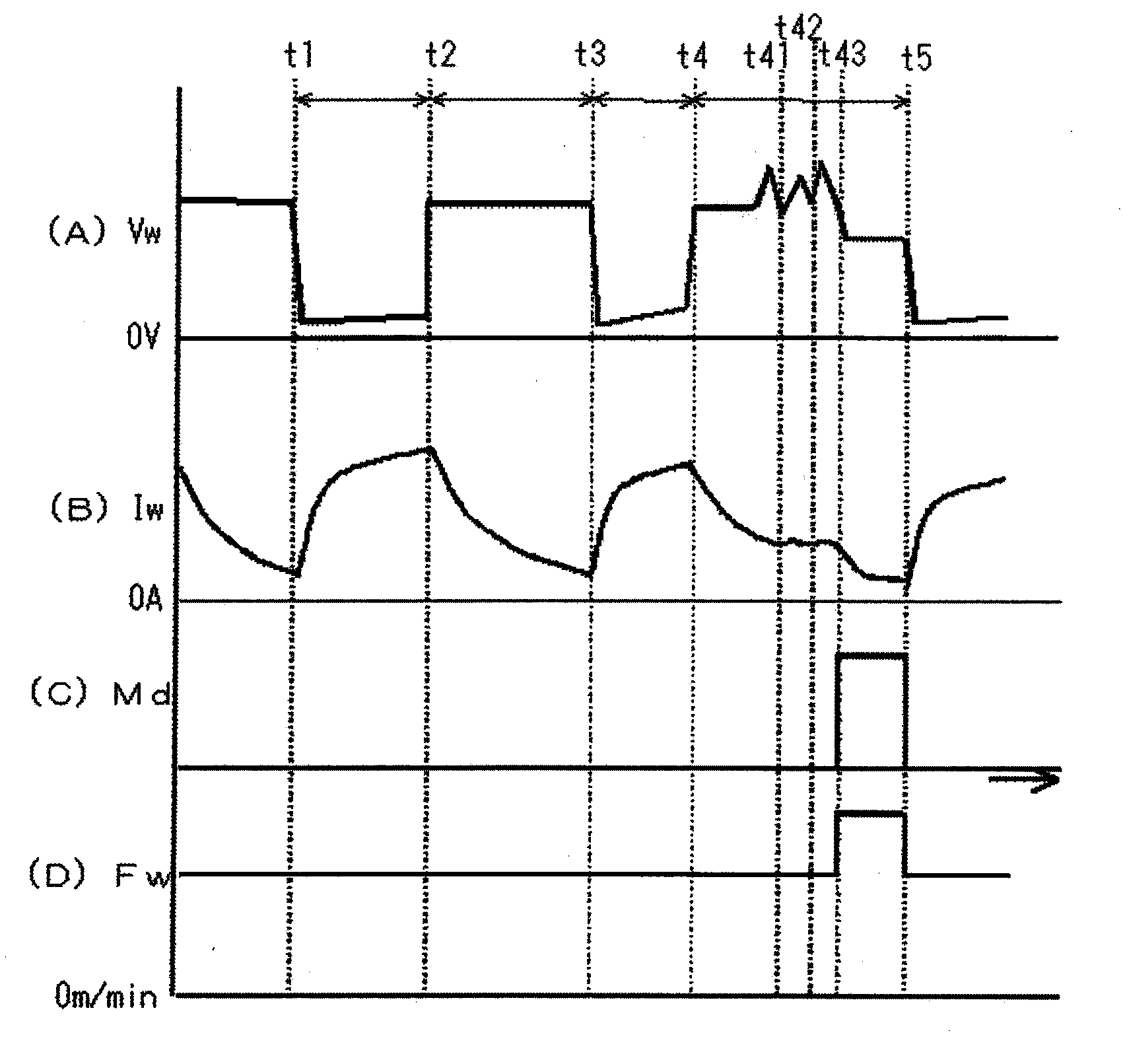

[0081] image 3 It is a voltage / current waveform diagram which shows the output control method of the welding power supply concerning Embodiment 2 of this invention. image 3 (A) represents the waveform of the welding voltage Vw, image 3 (B) represents the waveform of the welding current Iw, image 3 (C) shows the waveform of the droplet state determination signal Md, image 3 (D) shows the waveform of the feed rate Fw. image 3 It is carbon dioxide arc welding with an average welding current of 230A. image 3 Indicates a 2-cycle waveform. During the period from time t1 to t3, there is no gas ejection from the molten pool, so the welding state is stable, and gas ejection from the molten pool occurs during the period from time t3 to t5. image 3 corresponding to the above figure 1 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com