Cross flow guide type stirring paddle applied to fermentation tank

A cross-flow oriented, impeller technology, used in bioreactor/fermenter combinations, specific-purpose bioreactors/fermenters, mixer accessories, etc., can solve shear damage, microbial growth and normal metabolism. Influence and other problems, to achieve the effect of small shear damage, favorable for gas-liquid two-phase dispersion, and enhanced heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

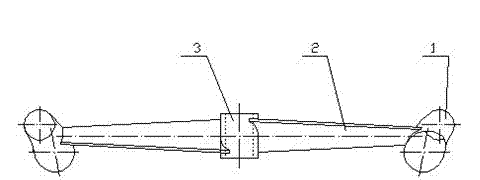

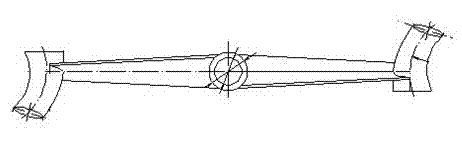

[0022] The cross-flow guiding impeller includes a hub 3, an arc-shaped inclined blade paddle 2 and a cross-flow guiding pipe 1, as shown in the attached Figure 1-2 shown. The hub 3 has a diameter of 35mm and a height of 40mm, and the diameter of the entire stirring paddle is 390mm (from the outer end of the guide tube of one of the two symmetrical blades to the outer end of the guide tube of the other), the arc-shaped inclined blade paddle 2 has a diameter of 330mm (from the inner end of the guide tube of one of the two symmetrical blades to the inner end of the guide tube of the other), the root section size of the arc-shaped inclined blade paddle is (radius R50mm, arc 45o), and the end section size For (radius R50mm, arc 23o). The inlet of the cross-flow guide pipe 1 faces downward and the outlet faces upward, the installation surface of the cross-flow guide pipe and the rotation plane of the stirring paddle form an included angle of 25°, the inlet plane of the cross-flow ...

Embodiment 2

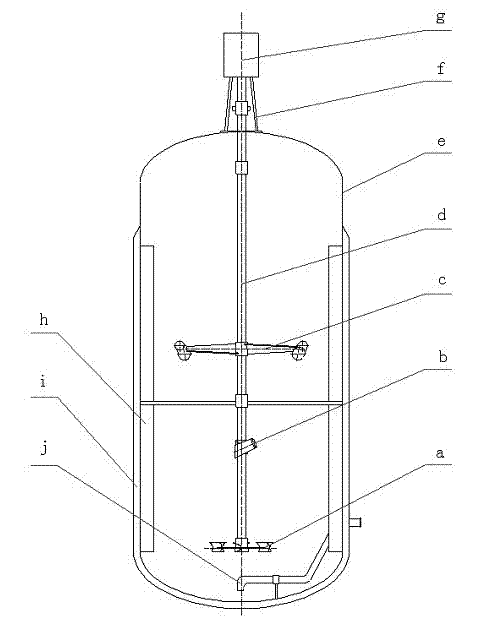

[0024] The cross-flow guiding stirring paddle can be applied in the ventilation fermenter, as attached image 3 shown. The fermenter system mainly includes: a, Chemineer BT-6 stirring paddle; b, cross-flow-guided stirring paddle; c, cross-flow-guided stirring paddle; d, shaft; e, fermentation tank container; f, frame; g, Motor; h, baffle; i, jacket; j, intake pipe. The upper two impellers are cross-flow oriented impellers, and the bottom impellers are Chemineer BT-6 or zigzag symmetrical oblique blade impellers (Chinese patent 200820237972.2). The combined agitation system can be applied to high-viscosity ventilation fermentation process. The bottom paddle diameter (d1) is 1 / 3 of the diameter D of the fermenter, and the distance from the bottom paddle to the bottom of the fermenter is 1.0 d1; the upper two-layer paddle adopts the cross-flow guiding paddle described in the present invention, and the diameter (d2) of the paddle is 2 / 3 of the diameter of the fermentation tank D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com