Shaped aluminum object for manufacturing integrally injection-molded aluminum/resin article, integrally injection-molded aluminum/resin article using same, and method for manufacturing shaped aluminum object and article

A manufacturing method and technology of formed products, applied in the direction of coating, etc., can solve the problems of pollution, crushing, fracture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

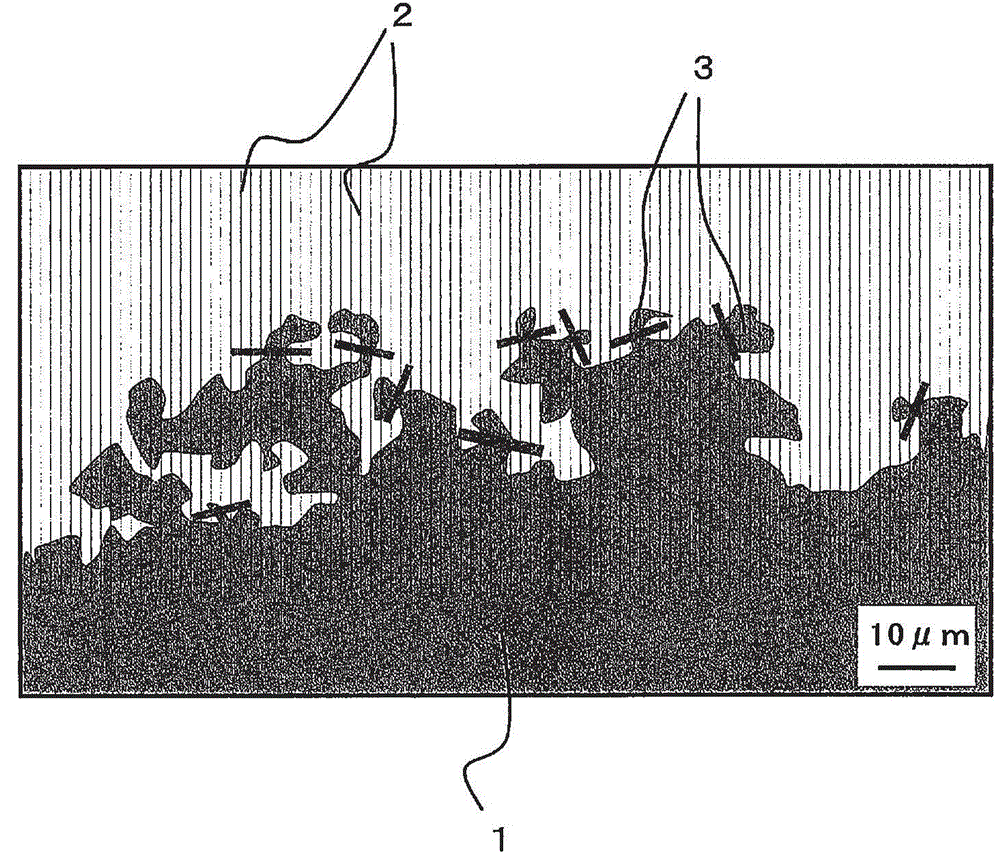

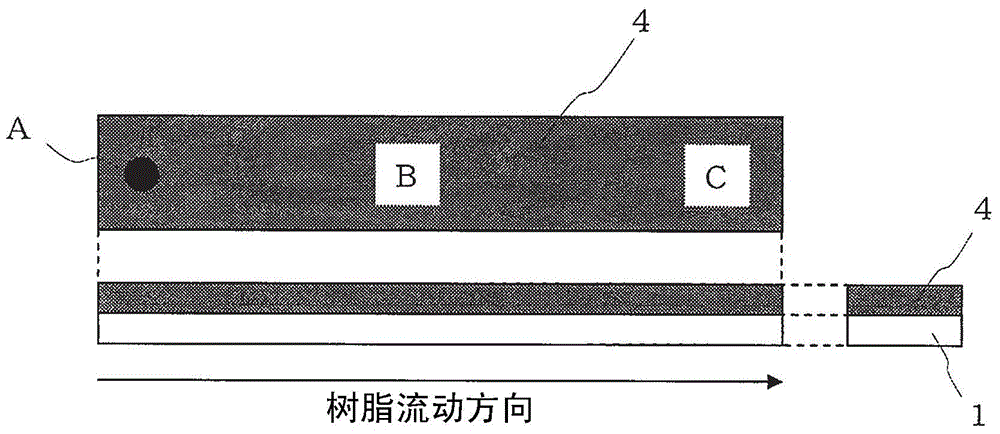

[0060] [Preparation of Aluminum Shaped Body]

[0061] Cut out an aluminum test piece with a size of 10mm×150mm from an aluminum alloy (JISA5052-H34) plate with a thickness of 2mm, and perform pretreatment on it: first, immerse the aluminum test piece in 30% by weight of nitric acid aqueous solution at room temperature for 5 minutes After that, it was fully washed with ion-exchanged water, then immersed in 5% by weight sodium hydroxide solution at 50° C. for 1 minute, then washed with water, and then immersed in 30% by weight of nitric acid aqueous solution at room temperature for 3 minutes, then washed with water.

[0062] Next, an etching treatment is carried out, that is, adding 54 g / L aluminum chloride hexahydrate (AlCl 3 ·6H 2 O) washing after immersion in the prepared etching solution (chloride ion concentration: 48g / L) for 4 minutes; then, the main treatment: immersion in 30% by weight nitric acid aqueous solution at room temperature for 3 minutes and then washing.

[...

Embodiment 2

[0077] It carried out similarly to Example 1 except having replaced the aluminum flake removal process with the process of immersing in 1 g / L sodium hydroxide solution for 0.5 minute at 40 degreeC. The results are shown in Table 1.

Embodiment 3

[0079] It carried out similarly to Example 1 except having replaced the aluminum flake removal process with the process of immersing in 10 g / L sodium hydroxide solution for 2 minutes at 40 degreeC. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion amount | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com