A method for reducing the temperature rise of half-speed high-current collector ring device

A slip ring, high current technology, applied in electromechanical devices, cooling/ventilation devices, electrical components, etc., can solve the problem of increased slip ring surface temperature rise, increased collector ring electrical loss, reduced centrifugal fan cooling effect, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the present invention more obvious and understandable, the present invention will be further described with preferred embodiments.

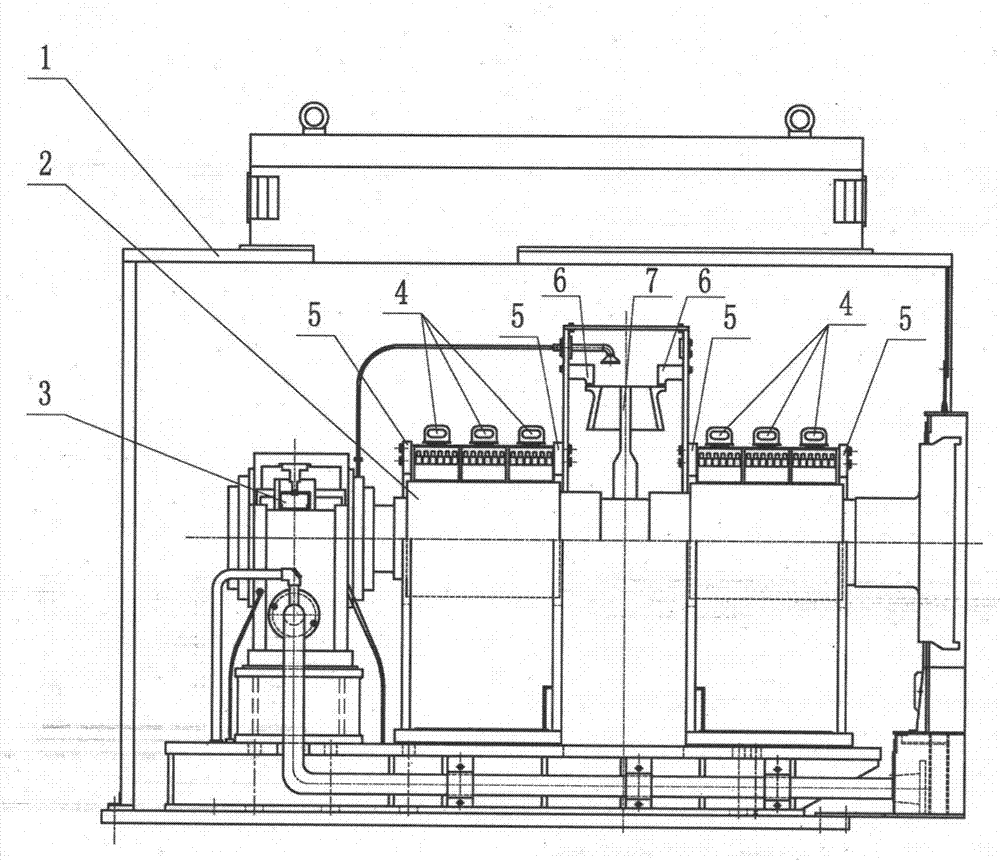

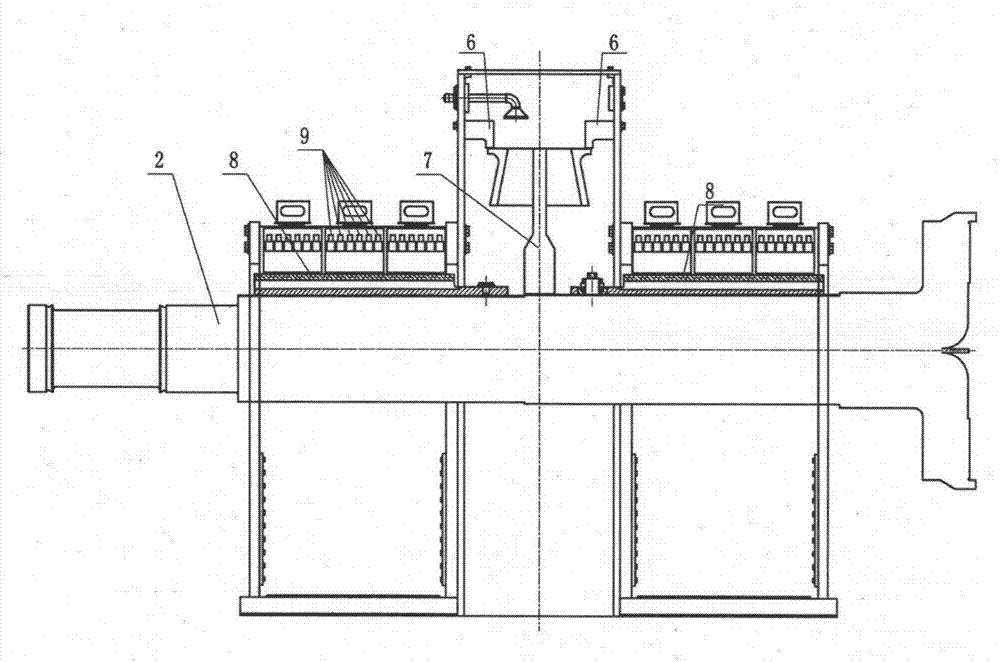

[0020] combine Figure 1 to Figure 3 , the invention provides a method for reducing the temperature rise of a half-speed high-current slip ring device, the steps of which are:

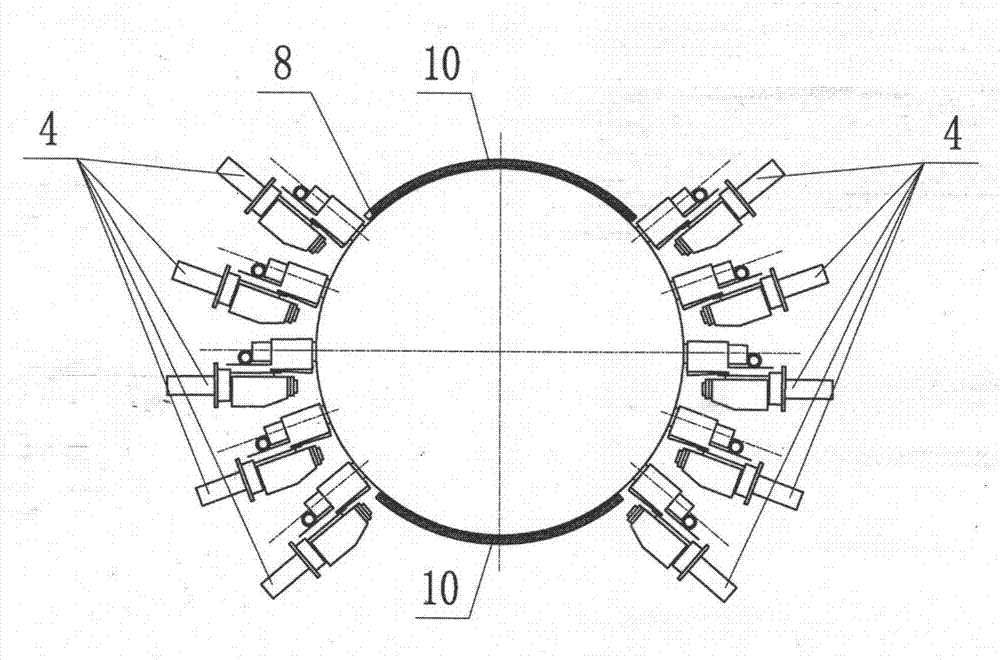

[0021] Step 1. Increase the diameter of the collector ring 2 to 450mm, increase the number of carbon brushes 9 to 360, optimize the arrangement of the carbon brushes 9 on the collector ring 2, reduce the current density of each carbon brush, and prevent local overheat. Each slip ring 8 assembled on the collector ring 2 is equipped with 3 rows in the axial direction, and each row has 10 combined brush holders 4 in the circumferential direction, and each combined brush holder 4 is equipped with 6 carbon brushes 9 .

[0022] Step 2. Increase the diameter of the centrifugal fan 7 located between a pair of slip rings 8 to 1200mm to make up for the los...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com